PDF Publication Title:

Text from PDF Page: 017

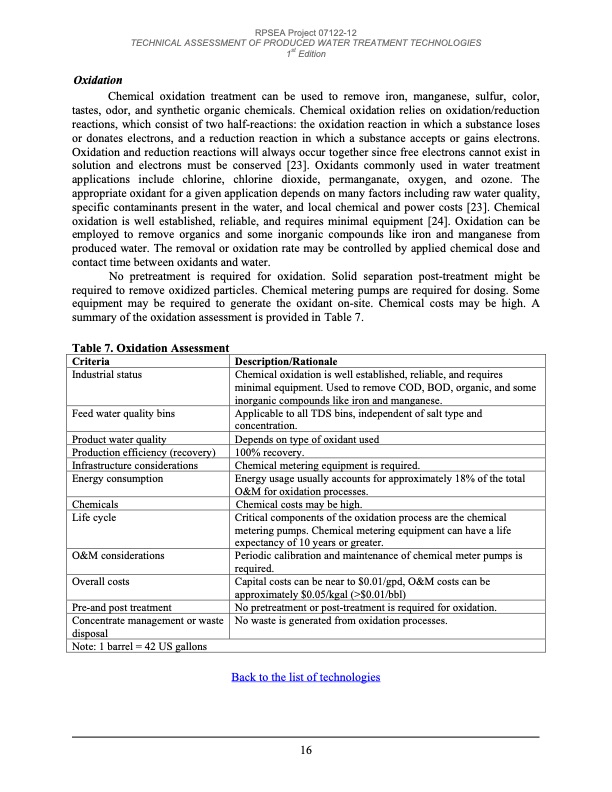

RPSEA Project 07122-12 TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES 1st Edition Oxidation Chemical oxidation treatment can be used to remove iron, manganese, sulfur, color, tastes, odor, and synthetic organic chemicals. Chemical oxidation relies on oxidation/reduction reactions, which consist of two half-reactions: the oxidation reaction in which a substance loses or donates electrons, and a reduction reaction in which a substance accepts or gains electrons. Oxidation and reduction reactions will always occur together since free electrons cannot exist in solution and electrons must be conserved [23]. Oxidants commonly used in water treatment applications include chlorine, chlorine dioxide, permanganate, oxygen, and ozone. The appropriate oxidant for a given application depends on many factors including raw water quality, specific contaminants present in the water, and local chemical and power costs [23]. Chemical oxidation is well established, reliable, and requires minimal equipment [24]. Oxidation can be employed to remove organics and some inorganic compounds like iron and manganese from produced water. The removal or oxidation rate may be controlled by applied chemical dose and contact time between oxidants and water. No pretreatment is required for oxidation. Solid separation post-treatment might be required to remove oxidized particles. Chemical metering pumps are required for dosing. Some equipment may be required to generate the oxidant on-site. Chemical costs may be high. A summary of the oxidation assessment is provided in Table 7. Table 7. Oxidation Assessment Criteria Industrial status Feed water quality bins Product water quality Production efficiency (recovery) Infrastructure considerations Energy consumption Chemicals Life cycle O&M considerations Overall costs Pre-and post treatment Concentrate management or waste disposal Note: 1 barrel = 42 US gallons Description/Rationale Chemical oxidation is well established, reliable, and requires minimal equipment. Used to remove COD, BOD, organic, and some inorganic compounds like iron and manganese. Applicable to all TDS bins, independent of salt type and concentration. Depends on type of oxidant used 100% recovery. Chemical metering equipment is required. Energy usage usually accounts for approximately 18% of the total O&M for oxidation processes. Chemical costs may be high. Critical components of the oxidation process are the chemical metering pumps. Chemical metering equipment can have a life expectancy of 10 years or greater. Periodic calibration and maintenance of chemical meter pumps is required. Capital costs can be near to $0.01/gpd, O&M costs can be approximately $0.05/kgal (>$0.01/bbl) No pretreatment or post-treatment is required for oxidation. No waste is generated from oxidation processes. Back to the list of technologies 16PDF Image | TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES

PDF Search Title:

TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIESOriginal File Name Searched:

Tech_Assessment_PW_Treatment_Tech.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |