PDF Publication Title:

Text from PDF Page: 019

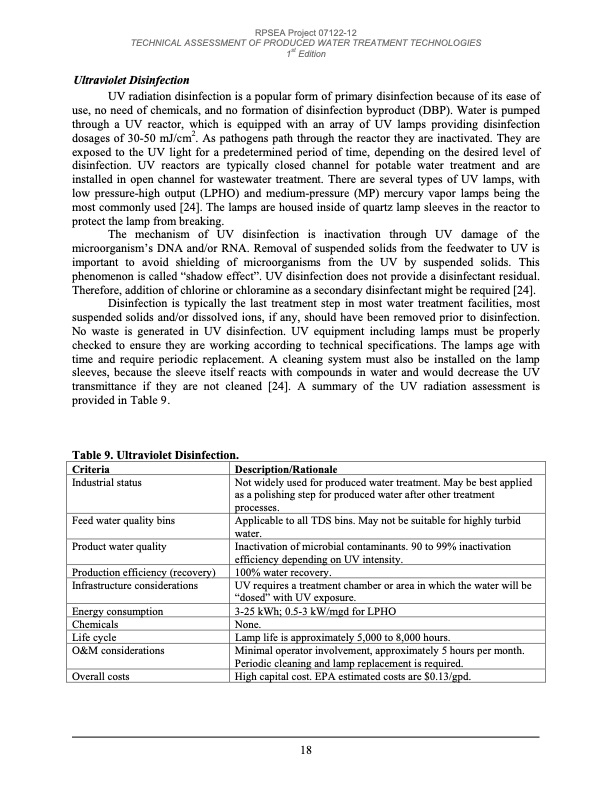

RPSEA Project 07122-12 TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES 1st Edition Ultraviolet Disinfection UV radiation disinfection is a popular form of primary disinfection because of its ease of use, no need of chemicals, and no formation of disinfection byproduct (DBP). Water is pumped through a UV reactor, which is equipped with an array of UV lamps providing disinfection dosages of 30-50 mJ/cm2. As pathogens path through the reactor they are inactivated. They are exposed to the UV light for a predetermined period of time, depending on the desired level of disinfection. UV reactors are typically closed channel for potable water treatment and are installed in open channel for wastewater treatment. There are several types of UV lamps, with low pressure-high output (LPHO) and medium-pressure (MP) mercury vapor lamps being the most commonly used [24]. The lamps are housed inside of quartz lamp sleeves in the reactor to protect the lamp from breaking. The mechanism of UV disinfection is inactivation through UV damage of the microorganism’s DNA and/or RNA. Removal of suspended solids from the feedwater to UV is important to avoid shielding of microorganisms from the UV by suspended solids. This phenomenon is called “shadow effect”. UV disinfection does not provide a disinfectant residual. Therefore, addition of chlorine or chloramine as a secondary disinfectant might be required [24]. Disinfection is typically the last treatment step in most water treatment facilities, most suspended solids and/or dissolved ions, if any, should have been removed prior to disinfection. No waste is generated in UV disinfection. UV equipment including lamps must be properly checked to ensure they are working according to technical specifications. The lamps age with time and require periodic replacement. A cleaning system must also be installed on the lamp sleeves, because the sleeve itself reacts with compounds in water and would decrease the UV transmittance if they are not cleaned [24]. A summary of the UV radiation assessment is provided in Table 9. Table 9. Ultraviolet Disinfection. Criteria Industrial status Feed water quality bins Product water quality Production efficiency (recovery) Infrastructure considerations Energy consumption Chemicals Life cycle O&M considerations Overall costs Description/Rationale Not widely used for produced water treatment. May be best applied as a polishing step for produced water after other treatment processes. Applicable to all TDS bins. May not be suitable for highly turbid water. Inactivation of microbial contaminants. 90 to 99% inactivation efficiency depending on UV intensity. 100% water recovery. UV requires a treatment chamber or area in which the water will be “dosed” with UV exposure. 3-25 kWh; 0.5-3 kW/mgd for LPHO None. Lamp life is approximately 5,000 to 8,000 hours. Minimal operator involvement, approximately 5 hours per month. Periodic cleaning and lamp replacement is required. High capital cost. EPA estimated costs are $0.13/gpd. 18PDF Image | TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES

PDF Search Title:

TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIESOriginal File Name Searched:

Tech_Assessment_PW_Treatment_Tech.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |