PDF Publication Title:

Text from PDF Page: 023

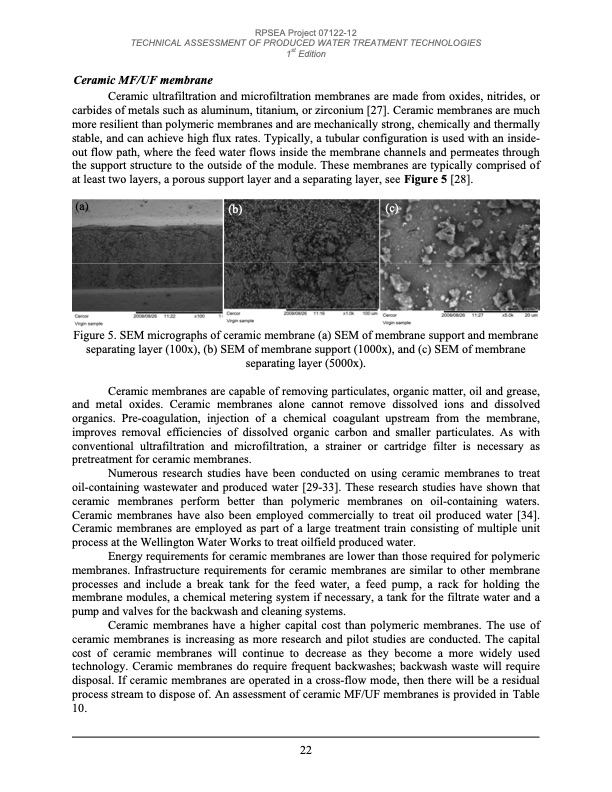

RPSEA Project 07122-12 TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES 1st Edition Ceramic MF/UF membrane Ceramic ultrafiltration and microfiltration membranes are made from oxides, nitrides, or carbides of metals such as aluminum, titanium, or zirconium [27]. Ceramic membranes are much more resilient than polymeric membranes and are mechanically strong, chemically and thermally stable, and can achieve high flux rates. Typically, a tubular configuration is used with an inside- out flow path, where the feed water flows inside the membrane channels and permeates through the support structure to the outside of the module. These membranes are typically comprised of at least two layers, a porous support layer and a separating layer, see Figure 5 [28]. (a) (b) (c) Figure 5. SEM micrographs of ceramic membrane (a) SEM of membrane support and membrane separating layer (100x), (b) SEM of membrane support (1000x), and (c) SEM of membrane separating layer (5000x). Ceramic membranes are capable of removing particulates, organic matter, oil and grease, and metal oxides. Ceramic membranes alone cannot remove dissolved ions and dissolved organics. Pre-coagulation, injection of a chemical coagulant upstream from the membrane, improves removal efficiencies of dissolved organic carbon and smaller particulates. As with conventional ultrafiltration and microfiltration, a strainer or cartridge filter is necessary as pretreatment for ceramic membranes. Numerous research studies have been conducted on using ceramic membranes to treat oil-containing wastewater and produced water [29-33]. These research studies have shown that ceramic membranes perform better than polymeric membranes on oil-containing waters. Ceramic membranes have also been employed commercially to treat oil produced water [34]. Ceramic membranes are employed as part of a large treatment train consisting of multiple unit process at the Wellington Water Works to treat oilfield produced water. Energy requirements for ceramic membranes are lower than those required for polymeric membranes. Infrastructure requirements for ceramic membranes are similar to other membrane processes and include a break tank for the feed water, a feed pump, a rack for holding the membrane modules, a chemical metering system if necessary, a tank for the filtrate water and a pump and valves for the backwash and cleaning systems. Ceramic membranes have a higher capital cost than polymeric membranes. The use of ceramic membranes is increasing as more research and pilot studies are conducted. The capital cost of ceramic membranes will continue to decrease as they become a more widely used technology. Ceramic membranes do require frequent backwashes; backwash waste will require disposal. If ceramic membranes are operated in a cross-flow mode, then there will be a residual process stream to dispose of. An assessment of ceramic MF/UF membranes is provided in Table 10. 22PDF Image | TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES

PDF Search Title:

TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIESOriginal File Name Searched:

Tech_Assessment_PW_Treatment_Tech.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |