PDF Publication Title:

Text from PDF Page: 024

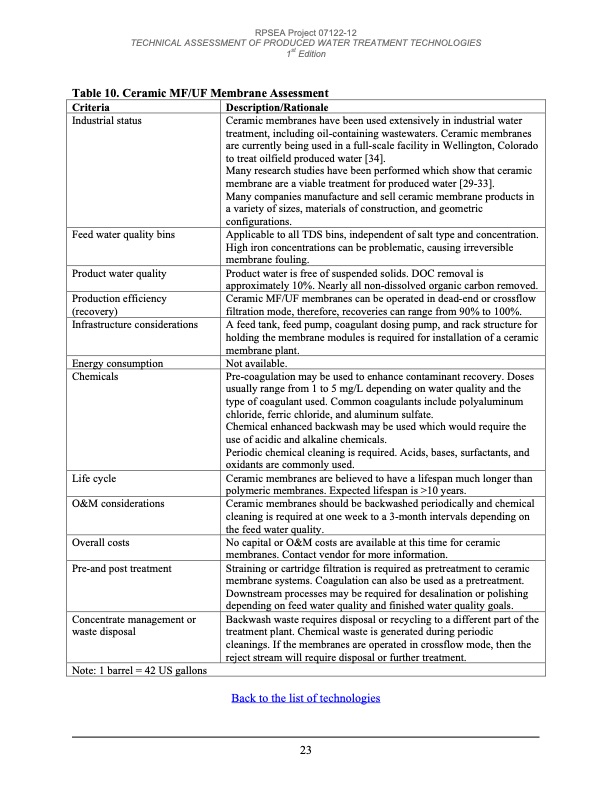

RPSEA Project 07122-12 TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES 1st Edition Table 10. Ceramic MF/UF Membrane Assessment Criteria Feed water quality bins Product water quality Production efficiency (recovery) Infrastructure considerations Energy consumption Life cycle O&M considerations Overall costs Note: 1 barrel = 42 US gallons Description/Rationale Applicable to all TDS bins, independent of salt type and concentration. High iron concentrations can be problematic, causing irreversible membrane fouling. Product water is free of suspended solids. DOC removal is approximately 10%. Nearly all non-dissolved organic carbon removed. Ceramic MF/UF membranes can be operated in dead-end or crossflow filtration mode, therefore, recoveries can range from 90% to 100%. A feed tank, feed pump, coagulant dosing pump, and rack structure for holding the membrane modules is required for installation of a ceramic membrane plant. Not available. Ceramic membranes are believed to have a lifespan much longer than polymeric membranes. Expected lifespan is >10 years. Ceramic membranes should be backwashed periodically and chemical cleaning is required at one week to a 3-month intervals depending on the feed water quality. No capital or O&M costs are available at this time for ceramic membranes. Contact vendor for more information. Industrial status Ceramic membranes have been used extensively in industrial water treatment, including oil-containing wastewaters. Ceramic membranes are currently being used in a full-scale facility in Wellington, Colorado to treat oilfield produced water [34]. Many research studies have been performed which show that ceramic membrane are a viable treatment for produced water [29-33]. Many companies manufacture and sell ceramic membrane products in a variety of sizes, materials of construction, and geometric configurations. Chemicals Pre-coagulation may be used to enhance contaminant recovery. Doses usually range from 1 to 5 mg/L depending on water quality and the type of coagulant used. Common coagulants include polyaluminum chloride, ferric chloride, and aluminum sulfate. Chemical enhanced backwash may be used which would require the use of acidic and alkaline chemicals. Periodic chemical cleaning is required. Acids, bases, surfactants, and oxidants are commonly used. Pre-and post treatment Straining or cartridge filtration is required as pretreatment to ceramic membrane systems. Coagulation can also be used as a pretreatment. Downstream processes may be required for desalination or polishing depending on feed water quality and finished water quality goals. Concentrate management or waste disposal Backwash waste requires disposal or recycling to a different part of the treatment plant. Chemical waste is generated during periodic cleanings. If the membranes are operated in crossflow mode, then the reject stream will require disposal or further treatment. Back to the list of technologies 23PDF Image | TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES

PDF Search Title:

TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIESOriginal File Name Searched:

Tech_Assessment_PW_Treatment_Tech.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |