PDF Publication Title:

Text from PDF Page: 027

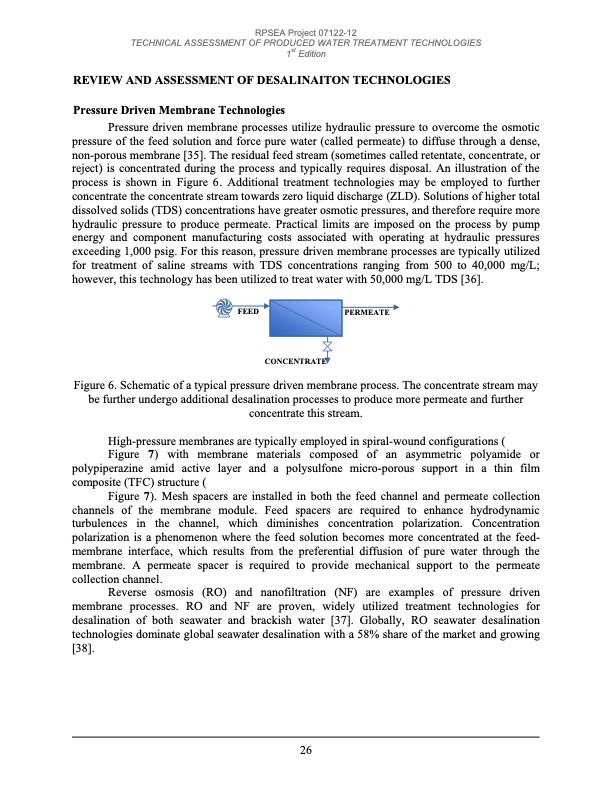

RPSEA Project 07122-12 TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES 1st Edition REVIEW AND ASSESSMENT OF DESALINAITON TECHNOLOGIES Pressure Driven Membrane Technologies Pressure driven membrane processes utilize hydraulic pressure to overcome the osmotic pressure of the feed solution and force pure water (called permeate) to diffuse through a dense, non-porous membrane [35]. The residual feed stream (sometimes called retentate, concentrate, or reject) is concentrated during the process and typically requires disposal. An illustration of the process is shown in Figure 6. Additional treatment technologies may be employed to further concentrate the concentrate stream towards zero liquid discharge (ZLD). Solutions of higher total dissolved solids (TDS) concentrations have greater osmotic pressures, and therefore require more hydraulic pressure to produce permeate. Practical limits are imposed on the process by pump energy and component manufacturing costs associated with operating at hydraulic pressures exceeding 1,000 psig. For this reason, pressure driven membrane processes are typically utilized for treatment of saline streams with TDS concentrations ranging from 500 to 40,000 mg/L; however, this technology has been utilized to treat water with 50,000 mg/L TDS [36]. FEED PERMEATE CONCENTRATE Figure 6. Schematic of a typical pressure driven membrane process. The concentrate stream may be further undergo additional desalination processes to produce more permeate and further concentrate this stream. High-pressure membranes are typically employed in spiral-wound configurations ( Figure 7) with membrane materials composed of an asymmetric polyamide or polypiperazine amid active layer and a polysulfone micro-porous support in a thin film composite (TFC) structure ( Figure 7). Mesh spacers are installed in both the feed channel and permeate collection channels of the membrane module. Feed spacers are required to enhance hydrodynamic turbulences in the channel, which diminishes concentration polarization. Concentration polarization is a phenomenon where the feed solution becomes more concentrated at the feed- membrane interface, which results from the preferential diffusion of pure water through the membrane. A permeate spacer is required to provide mechanical support to the permeate collection channel. Reverse osmosis (RO) and nanofiltration (NF) are examples of pressure driven membrane processes. RO and NF are proven, widely utilized treatment technologies for desalination of both seawater and brackish water [37]. Globally, RO seawater desalination technologies dominate global seawater desalination with a 58% share of the market and growing [38]. 26PDF Image | TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES

PDF Search Title:

TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIESOriginal File Name Searched:

Tech_Assessment_PW_Treatment_Tech.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |