PDF Publication Title:

Text from PDF Page: 029

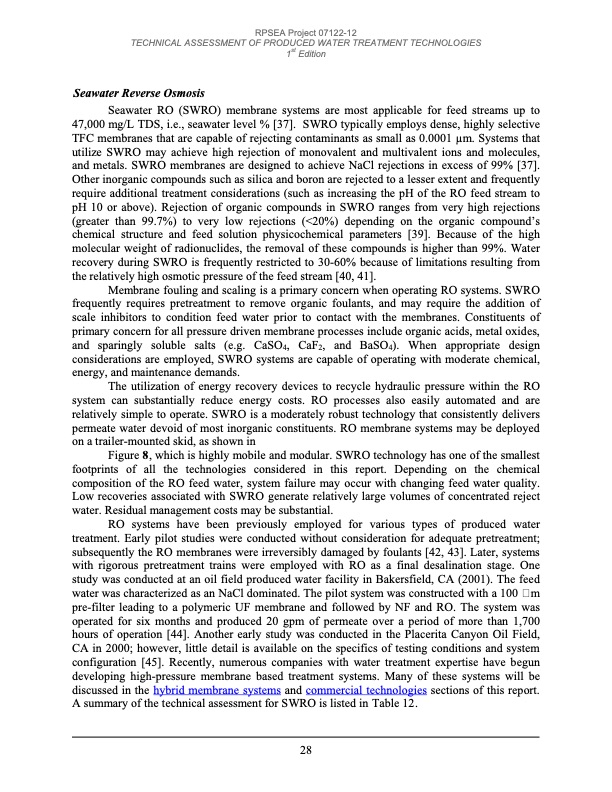

RPSEA Project 07122-12 TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES 1st Edition Seawater Reverse Osmosis Seawater RO (SWRO) membrane systems are most applicable for feed streams up to 47,000 mg/L TDS, i.e., seawater level % [37]. SWRO typically employs dense, highly selective TFC membranes that are capable of rejecting contaminants as small as 0.0001 μm. Systems that utilize SWRO may achieve high rejection of monovalent and multivalent ions and molecules, and metals. SWRO membranes are designed to achieve NaCl rejections in excess of 99% [37]. Other inorganic compounds such as silica and boron are rejected to a lesser extent and frequently require additional treatment considerations (such as increasing the pH of the RO feed stream to pH 10 or above). Rejection of organic compounds in SWRO ranges from very high rejections (greater than 99.7%) to very low rejections (<20%) depending on the organic compound’s chemical structure and feed solution physicochemical parameters [39]. Because of the high molecular weight of radionuclides, the removal of these compounds is higher than 99%. Water recovery during SWRO is frequently restricted to 30-60% because of limitations resulting from the relatively high osmotic pressure of the feed stream [40, 41]. Membrane fouling and scaling is a primary concern when operating RO systems. SWRO frequently requires pretreatment to remove organic foulants, and may require the addition of scale inhibitors to condition feed water prior to contact with the membranes. Constituents of primary concern for all pressure driven membrane processes include organic acids, metal oxides, and sparingly soluble salts (e.g. CaSO4, CaF2, and BaSO4). When appropriate design considerations are employed, SWRO systems are capable of operating with moderate chemical, energy, and maintenance demands. The utilization of energy recovery devices to recycle hydraulic pressure within the RO system can substantially reduce energy costs. RO processes also easily automated and are relatively simple to operate. SWRO is a moderately robust technology that consistently delivers permeate water devoid of most inorganic constituents. RO membrane systems may be deployed on a trailer-mounted skid, as shown in Figure 8, which is highly mobile and modular. SWRO technology has one of the smallest footprints of all the technologies considered in this report. Depending on the chemical composition of the RO feed water, system failure may occur with changing feed water quality. Low recoveries associated with SWRO generate relatively large volumes of concentrated reject water. Residual management costs may be substantial. RO systems have been previously employed for various types of produced water treatment. Early pilot studies were conducted without consideration for adequate pretreatment; subsequently the RO membranes were irreversibly damaged by foulants [42, 43]. Later, systems with rigorous pretreatment trains were employed with RO as a final desalination stage. One study was conducted at an oil field produced water facility in Bakersfield, CA (2001). The feed water was characterized as an NaCl dominated. The pilot system was constructed with a 100 �m pre-filter leading to a polymeric UF membrane and followed by NF and RO. The system was operated for six months and produced 20 gpm of permeate over a period of more than 1,700 hours of operation [44]. Another early study was conducted in the Placerita Canyon Oil Field, CA in 2000; however, little detail is available on the specifics of testing conditions and system configuration [45]. Recently, numerous companies with water treatment expertise have begun developing high-pressure membrane based treatment systems. Many of these systems will be discussed in the hybrid membrane systems and commercial technologies sections of this report. A summary of the technical assessment for SWRO is listed in Table 12. 28PDF Image | TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES

PDF Search Title:

TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIESOriginal File Name Searched:

Tech_Assessment_PW_Treatment_Tech.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |