PDF Publication Title:

Text from PDF Page: 044

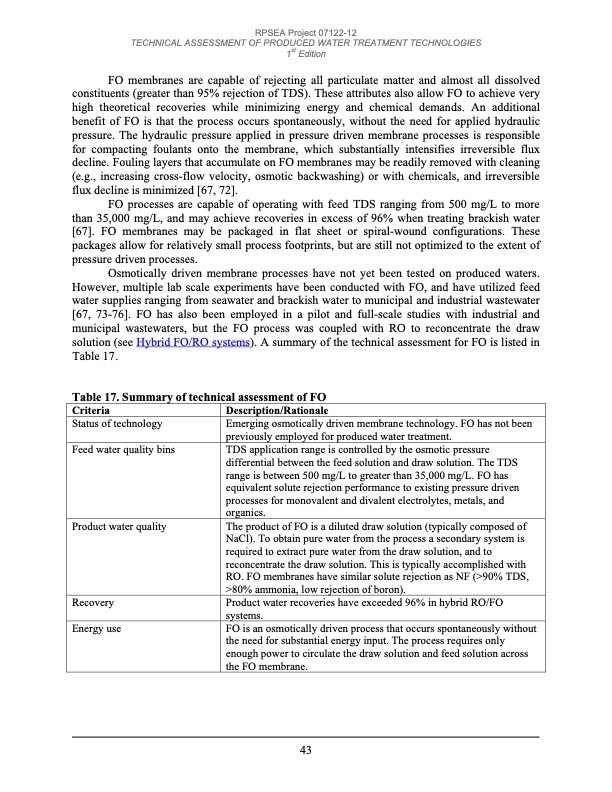

RPSEA Project 07122-12 TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES 1st Edition FO membranes are capable of rejecting all particulate matter and almost all dissolved constituents (greater than 95% rejection of TDS). These attributes also allow FO to achieve very high theoretical recoveries while minimizing energy and chemical demands. An additional benefit of FO is that the process occurs spontaneously, without the need for applied hydraulic pressure. The hydraulic pressure applied in pressure driven membrane processes is responsible for compacting foulants onto the membrane, which substantially intensifies irreversible flux decline. Fouling layers that accumulate on FO membranes may be readily removed with cleaning (e.g., increasing cross-flow velocity, osmotic backwashing) or with chemicals, and irreversible flux decline is minimized [67, 72]. FO processes are capable of operating with feed TDS ranging from 500 mg/L to more than 35,000 mg/L, and may achieve recoveries in excess of 96% when treating brackish water [67]. FO membranes may be packaged in flat sheet or spiral-wound configurations. These packages allow for relatively small process footprints, but are still not optimized to the extent of pressure driven processes. Osmotically driven membrane processes have not yet been tested on produced waters. However, multiple lab scale experiments have been conducted with FO, and have utilized feed water supplies ranging from seawater and brackish water to municipal and industrial wastewater [67, 73-76]. FO has also been employed in a pilot and full-scale studies with industrial and municipal wastewaters, but the FO process was coupled with RO to reconcentrate the draw solution (see Hybrid FO/RO systems). A summary of the technical assessment for FO is listed in Table 17. Table 17. Summary of technical assessment of FO Criteria Status of technology Description/Rationale Emerging osmotically driven membrane technology. FO has not been previously employed for produced water treatment. Feed water quality bins TDS application range is controlled by the osmotic pressure differential between the feed solution and draw solution. The TDS range is between 500 mg/L to greater than 35,000 mg/L. FO has equivalent solute rejection performance to existing pressure driven processes for monovalent and divalent electrolytes, metals, and organics. Product water quality The product of FO is a diluted draw solution (typically composed of NaCl). To obtain pure water from the process a secondary system is required to extract pure water from the draw solution, and to reconcentrate the draw solution. This is typically accomplished with RO. FO membranes have similar solute rejection as NF (>90% TDS, >80% ammonia, low rejection of boron). Recovery Product water recoveries have exceeded 96% in hybrid RO/FO systems. Energy use FO is an osmotically driven process that occurs spontaneously without the need for substantial energy input. The process requires only enough power to circulate the draw solution and feed solution across the FO membrane. 43PDF Image | TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES

PDF Search Title:

TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIESOriginal File Name Searched:

Tech_Assessment_PW_Treatment_Tech.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |