PDF Publication Title:

Text from PDF Page: 055

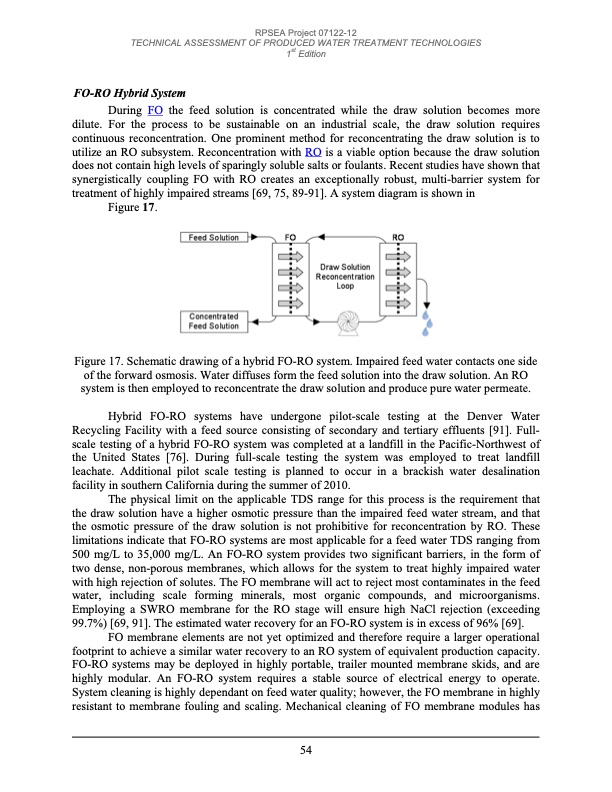

RPSEA Project 07122-12 TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES 1st Edition FO-RO Hybrid System During FO the feed solution is concentrated while the draw solution becomes more dilute. For the process to be sustainable on an industrial scale, the draw solution requires continuous reconcentration. One prominent method for reconcentrating the draw solution is to utilize an RO subsystem. Reconcentration with RO is a viable option because the draw solution does not contain high levels of sparingly soluble salts or foulants. Recent studies have shown that synergistically coupling FO with RO creates an exceptionally robust, multi-barrier system for treatment of highly impaired streams [69, 75, 89-91]. A system diagram is shown in Figure 17. Figure 17. Schematic drawing of a hybrid FO-RO system. Impaired feed water contacts one side of the forward osmosis. Water diffuses form the feed solution into the draw solution. An RO system is then employed to reconcentrate the draw solution and produce pure water permeate. Hybrid FO-RO systems have undergone pilot-scale testing at the Denver Water Recycling Facility with a feed source consisting of secondary and tertiary effluents [91]. Full- scale testing of a hybrid FO-RO system was completed at a landfill in the Pacific-Northwest of the United States [76]. During full-scale testing the system was employed to treat landfill leachate. Additional pilot scale testing is planned to occur in a brackish water desalination facility in southern California during the summer of 2010. The physical limit on the applicable TDS range for this process is the requirement that the draw solution have a higher osmotic pressure than the impaired feed water stream, and that the osmotic pressure of the draw solution is not prohibitive for reconcentration by RO. These limitations indicate that FO-RO systems are most applicable for a feed water TDS ranging from 500 mg/L to 35,000 mg/L. An FO-RO system provides two significant barriers, in the form of two dense, non-porous membranes, which allows for the system to treat highly impaired water with high rejection of solutes. The FO membrane will act to reject most contaminates in the feed water, including scale forming minerals, most organic compounds, and microorganisms. Employing a SWRO membrane for the RO stage will ensure high NaCl rejection (exceeding 99.7%) [69, 91]. The estimated water recovery for an FO-RO system is in excess of 96% [69]. FO membrane elements are not yet optimized and therefore require a larger operational footprint to achieve a similar water recovery to an RO system of equivalent production capacity. FO-RO systems may be deployed in highly portable, trailer mounted membrane skids, and are highly modular. An FO-RO system requires a stable source of electrical energy to operate. System cleaning is highly dependant on feed water quality; however, the FO membrane in highly resistant to membrane fouling and scaling. Mechanical cleaning of FO membrane modules has 54PDF Image | TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES

PDF Search Title:

TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIESOriginal File Name Searched:

Tech_Assessment_PW_Treatment_Tech.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |