PDF Publication Title:

Text from PDF Page: 061

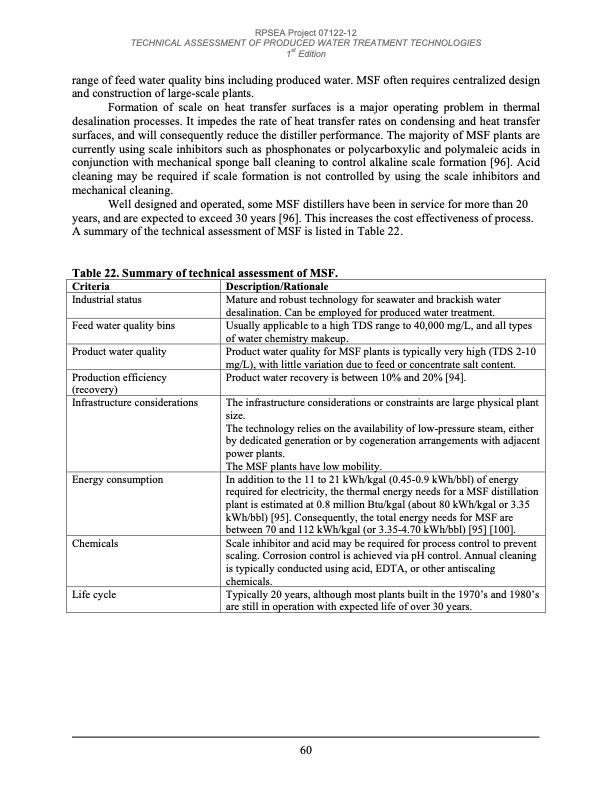

RPSEA Project 07122-12 TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES 1st Edition range of feed water quality bins including produced water. MSF often requires centralized design and construction of large-scale plants. Formation of scale on heat transfer surfaces is a major operating problem in thermal desalination processes. It impedes the rate of heat transfer rates on condensing and heat transfer surfaces, and will consequently reduce the distiller performance. The majority of MSF plants are currently using scale inhibitors such as phosphonates or polycarboxylic and polymaleic acids in conjunction with mechanical sponge ball cleaning to control alkaline scale formation [96]. Acid cleaning may be required if scale formation is not controlled by using the scale inhibitors and mechanical cleaning. Well designed and operated, some MSF distillers have been in service for more than 20 years, and are expected to exceed 30 years [96]. This increases the cost effectiveness of process. A summary of the technical assessment of MSF is listed in Table 22. Table 22. Summary of technical assessment of MSF. Criteria Industrial status Feed water quality bins Product water quality Production efficiency (recovery) Description/Rationale Mature and robust technology for seawater and brackish water desalination. Can be employed for produced water treatment. Usually applicable to a high TDS range to 40,000 mg/L, and all types of water chemistry makeup. Product water quality for MSF plants is typically very high (TDS 2-10 mg/L), with little variation due to feed or concentrate salt content. Product water recovery is between 10% and 20% [94]. Infrastructure considerations The infrastructure considerations or constraints are large physical plant size. The technology relies on the availability of low-pressure steam, either by dedicated generation or by cogeneration arrangements with adjacent power plants. The MSF plants have low mobility. Energy consumption In addition to the 11 to 21 kWh/kgal (0.45-0.9 kWh/bbl) of energy required for electricity, the thermal energy needs for a MSF distillation plant is estimated at 0.8 million Btu/kgal (about 80 kWh/kgal or 3.35 kWh/bbl) [95]. Consequently, the total energy needs for MSF are between 70 and 112 kWh/kgal (or 3.35-4.70 kWh/bbl) [95] [100]. Chemicals Scale inhibitor and acid may be required for process control to prevent scaling. Corrosion control is achieved via pH control. Annual cleaning is typically conducted using acid, EDTA, or other antiscaling chemicals. Life cycle Typically 20 years, although most plants built in the 1970’s and 1980’s are still in operation with expected life of over 30 years. 60PDF Image | TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES

PDF Search Title:

TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIESOriginal File Name Searched:

Tech_Assessment_PW_Treatment_Tech.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |