PDF Publication Title:

Text from PDF Page: 063

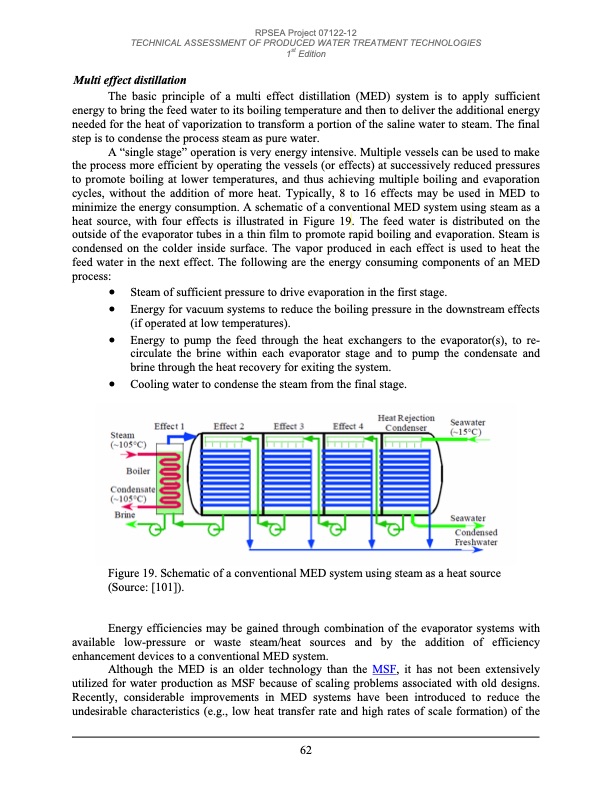

RPSEA Project 07122-12 TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES 1st Edition Multi effect distillation The basic principle of a multi effect distillation (MED) system is to apply sufficient energy to bring the feed water to its boiling temperature and then to deliver the additional energy needed for the heat of vaporization to transform a portion of the saline water to steam. The final step is to condense the process steam as pure water. A “single stage” operation is very energy intensive. Multiple vessels can be used to make the process more efficient by operating the vessels (or effects) at successively reduced pressures to promote boiling at lower temperatures, and thus achieving multiple boiling and evaporation cycles, without the addition of more heat. Typically, 8 to 16 effects may be used in MED to minimize the energy consumption. A schematic of a conventional MED system using steam as a heat source, with four effects is illustrated in Figure 19. The feed water is distributed on the outside of the evaporator tubes in a thin film to promote rapid boiling and evaporation. Steam is condensed on the colder inside surface. The vapor produced in each effect is used to heat the feed water in the next effect. The following are the energy consuming components of an MED process: Steam of sufficient pressure to drive evaporation in the first stage. Energy for vacuum systems to reduce the boiling pressure in the downstream effects (if operated at low temperatures). Energy to pump the feed through the heat exchangers to the evaporator(s), to re- circulate the brine within each evaporator stage and to pump the condensate and brine through the heat recovery for exiting the system. Cooling water to condense the steam from the final stage. Figure 19. Schematic of a conventional MED system using steam as a heat source (Source: [101]). Energy efficiencies may be gained through combination of the evaporator systems with available low-pressure or waste steam/heat sources and by the addition of efficiency enhancement devices to a conventional MED system. Although the MED is an older technology than the MSF, it has not been extensively utilized for water production as MSF because of scaling problems associated with old designs. Recently, considerable improvements in MED systems have been introduced to reduce the undesirable characteristics (e.g., low heat transfer rate and high rates of scale formation) of the 62PDF Image | TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES

PDF Search Title:

TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIESOriginal File Name Searched:

Tech_Assessment_PW_Treatment_Tech.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |