PDF Publication Title:

Text from PDF Page: 071

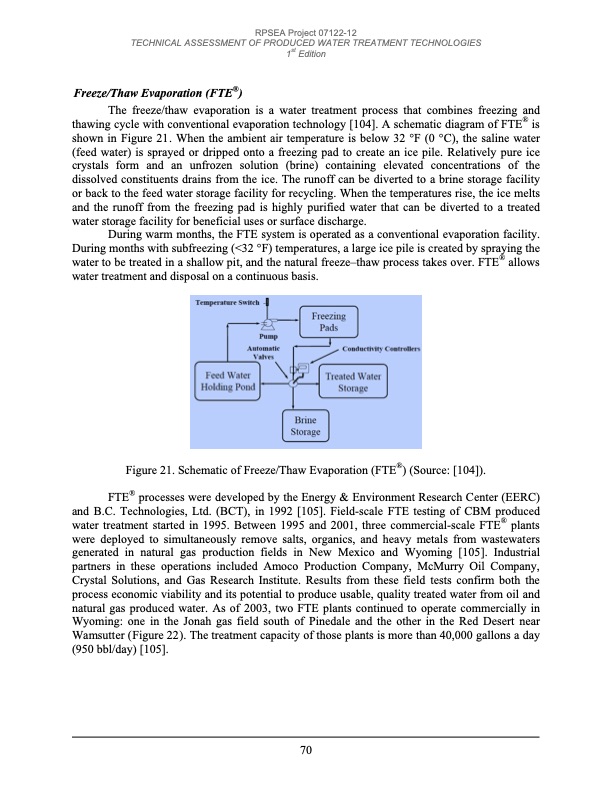

RPSEA Project 07122-12 TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES 1st Edition Freeze/Thaw Evaporation (FTE®) The freeze/thaw evaporation is a water treatment process that combines freezing and thawing cycle with conventional evaporation technology [104]. A schematic diagram of FTE® is shown in Figure 21. When the ambient air temperature is below 32 °F (0 °C), the saline water (feed water) is sprayed or dripped onto a freezing pad to create an ice pile. Relatively pure ice crystals form and an unfrozen solution (brine) containing elevated concentrations of the dissolved constituents drains from the ice. The runoff can be diverted to a brine storage facility or back to the feed water storage facility for recycling. When the temperatures rise, the ice melts and the runoff from the freezing pad is highly purified water that can be diverted to a treated water storage facility for beneficial uses or surface discharge. During warm months, the FTE system is operated as a conventional evaporation facility. During months with subfreezing (<32 °F) temperatures, a large ice pile is created by spraying the water to be treated in a shallow pit, and the natural freeze–thaw process takes over. FTE® allows water treatment and disposal on a continuous basis. Figure 21. Schematic of Freeze/Thaw Evaporation (FTE®) (Source: [104]). FTE® processes were developed by the Energy & Environment Research Center (EERC) and B.C. Technologies, Ltd. (BCT), in 1992 [105]. Field-scale FTE testing of CBM produced water treatment started in 1995. Between 1995 and 2001, three commercial-scale FTE® plants were deployed to simultaneously remove salts, organics, and heavy metals from wastewaters generated in natural gas production fields in New Mexico and Wyoming [105]. Industrial partners in these operations included Amoco Production Company, McMurry Oil Company, Crystal Solutions, and Gas Research Institute. Results from these field tests confirm both the process economic viability and its potential to produce usable, quality treated water from oil and natural gas produced water. As of 2003, two FTE plants continued to operate commercially in Wyoming: one in the Jonah gas field south of Pinedale and the other in the Red Desert near Wamsutter (Figure 22). The treatment capacity of those plants is more than 40,000 gallons a day (950 bbl/day) [105]. 70PDF Image | TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES

PDF Search Title:

TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIESOriginal File Name Searched:

Tech_Assessment_PW_Treatment_Tech.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |