PDF Publication Title:

Text from PDF Page: 073

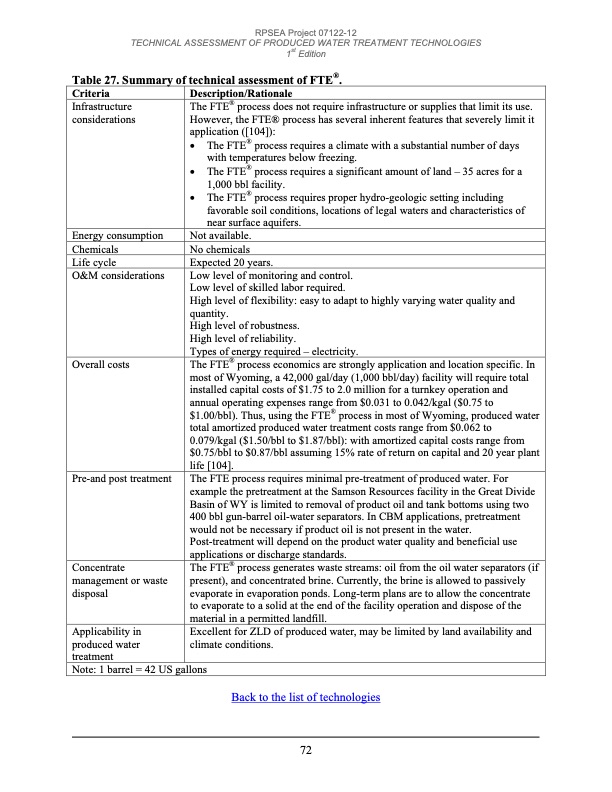

RPSEA Project 07122-12 TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES 1st Edition Table 27. Summary of technical assessment of FTE®. Criteria Description/Rationale Infrastructure considerations The FTE® process does not require infrastructure or supplies that limit its use. However, the FTE® process has several inherent features that severely limit it application ([104]): The FTE® process requires a climate with a substantial number of days with temperatures below freezing. The FTE® process requires a significant amount of land – 35 acres for a 1,000 bbl facility. The FTE® process requires proper hydro-geologic setting including favorable soil conditions, locations of legal waters and characteristics of near surface aquifers. Energy consumption Chemicals Life cycle Not available. No chemicals Expected 20 years. O&M considerations Low level of monitoring and control. Low level of skilled labor required. High level of flexibility: easy to adapt to highly varying water quality and quantity. High level of robustness. High level of reliability. Types of energy required – electricity. Overall costs The FTE® process economics are strongly application and location specific. In most of Wyoming, a 42,000 gal/day (1,000 bbl/day) facility will require total installed capital costs of $1.75 to 2.0 million for a turnkey operation and annual operating expenses range from $0.031 to 0.042/kgal ($0.75 to $1.00/bbl). Thus, using the FTE® process in most of Wyoming, produced water total amortized produced water treatment costs range from $0.062 to 0.079/kgal ($1.50/bbl to $1.87/bbl): with amortized capital costs range from $0.75/bbl to $0.87/bbl assuming 15% rate of return on capital and 20 year plant life [104]. Pre-and post treatment The FTE process requires minimal pre-treatment of produced water. For example the pretreatment at the Samson Resources facility in the Great Divide Basin of WY is limited to removal of product oil and tank bottoms using two 400 bbl gun-barrel oil-water separators. In CBM applications, pretreatment would not be necessary if product oil is not present in the water. Post-treatment will depend on the product water quality and beneficial use applications or discharge standards. Concentrate management or waste disposal The FTE® process generates waste streams: oil from the oil water separators (if present), and concentrated brine. Currently, the brine is allowed to passively evaporate in evaporation ponds. Long-term plans are to allow the concentrate to evaporate to a solid at the end of the facility operation and dispose of the material in a permitted landfill. Applicability in produced water treatment Note: 1 barrel = 42 US gallons Excellent for ZLD of produced water, may be limited by land availability and climate conditions. Back to the list of technologies 72PDF Image | TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES

PDF Search Title:

TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIESOriginal File Name Searched:

Tech_Assessment_PW_Treatment_Tech.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |