PDF Publication Title:

Text from PDF Page: 091

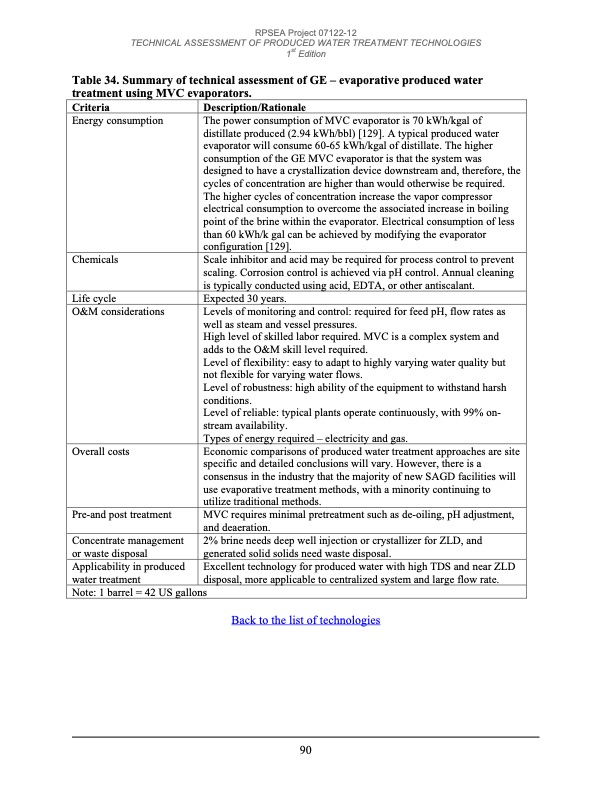

RPSEA Project 07122-12 TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES 1st Edition Table 34. Summary of technical assessment of GE – evaporative produced water treatment using MVC evaporators. Criteria Description/Rationale Energy consumption The power consumption of MVC evaporator is 70 kWh/kgal of distillate produced (2.94 kWh/bbl) [129]. A typical produced water evaporator will consume 60-65 kWh/kgal of distillate. The higher consumption of the GE MVC evaporator is that the system was designed to have a crystallization device downstream and, therefore, the cycles of concentration are higher than would otherwise be required. The higher cycles of concentration increase the vapor compressor electrical consumption to overcome the associated increase in boiling point of the brine within the evaporator. Electrical consumption of less than 60 kWh/k gal can be achieved by modifying the evaporator configuration [129]. Chemicals Life cycle Scale inhibitor and acid may be required for process control to prevent scaling. Corrosion control is achieved via pH control. Annual cleaning is typically conducted using acid, EDTA, or other antiscalant. Expected 30 years. O&M considerations Levels of monitoring and control: required for feed pH, flow rates as well as steam and vessel pressures. High level of skilled labor required. MVC is a complex system and adds to the O&M skill level required. Level of flexibility: easy to adapt to highly varying water quality but not flexible for varying water flows. Level of robustness: high ability of the equipment to withstand harsh conditions. Level of reliable: typical plants operate continuously, with 99% on- stream availability. Types of energy required – electricity and gas. Overall costs Economic comparisons of produced water treatment approaches are site specific and detailed conclusions will vary. However, there is a consensus in the industry that the majority of new SAGD facilities will use evaporative treatment methods, with a minority continuing to utilize traditional methods. Pre-and post treatment Concentrate management or waste disposal Applicability in produced water treatment MVC requires minimal pretreatment such as de-oiling, pH adjustment, and deaeration. 2% brine needs deep well injection or crystallizer for ZLD, and generated solid solids need waste disposal. Excellent technology for produced water with high TDS and near ZLD disposal, more applicable to centralized system and large flow rate. Note: 1 barrel = 42 US gallons Back to the list of technologies 90PDF Image | TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES

PDF Search Title:

TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIESOriginal File Name Searched:

Tech_Assessment_PW_Treatment_Tech.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |