PDF Publication Title:

Text from PDF Page: 111

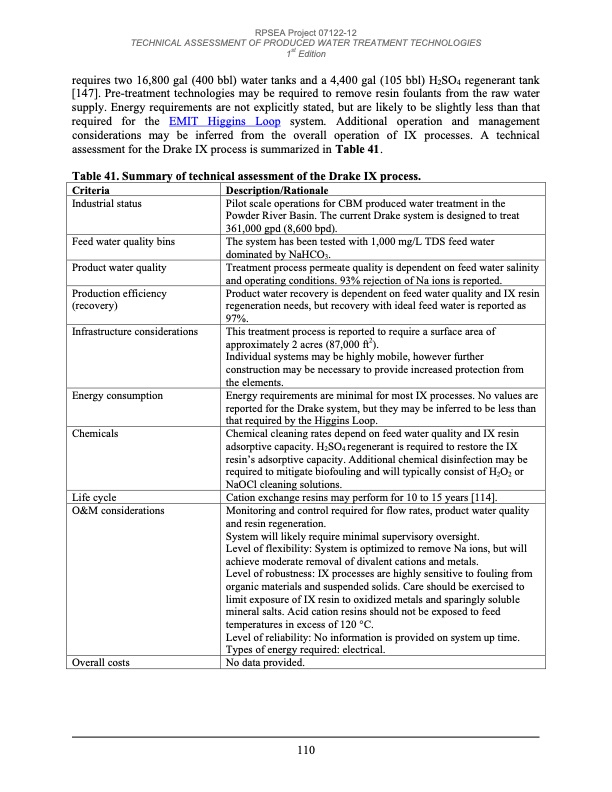

RPSEA Project 07122-12 TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES 1st Edition requires two 16,800 gal (400 bbl) water tanks and a 4,400 gal (105 bbl) H2SO4 regenerant tank [147]. Pre-treatment technologies may be required to remove resin foulants from the raw water supply. Energy requirements are not explicitly stated, but are likely to be slightly less than that required for the EMIT Higgins Loop system. Additional operation and management considerations may be inferred from the overall operation of IX processes. A technical assessment for the Drake IX process is summarized in Table 41. Table 41. Summary of technical assessment of the Drake IX process. Criteria Industrial status Feed water quality bins Product water quality Production efficiency (recovery) Energy consumption Life cycle Description/Rationale Pilot scale operations for CBM produced water treatment in the Powder River Basin. The current Drake system is designed to treat 361,000 gpd (8,600 bpd). The system has been tested with 1,000 mg/L TDS feed water dominated by NaHCO3. Treatment process permeate quality is dependent on feed water salinity and operating conditions. 93% rejection of Na ions is reported. Product water recovery is dependent on feed water quality and IX resin regeneration needs, but recovery with ideal feed water is reported as 97%. Energy requirements are minimal for most IX processes. No values are reported for the Drake system, but they may be inferred to be less than that required by the Higgins Loop. Cation exchange resins may perform for 10 to 15 years [114]. Infrastructure considerations This treatment process is reported to require a surface area of approximately 2 acres (87,000 ft2). Individual systems may be highly mobile, however further construction may be necessary to provide increased protection from the elements. Chemicals Chemical cleaning rates depend on feed water quality and IX resin adsorptive capacity. H2SO4 regenerant is required to restore the IX resin’s adsorptive capacity. Additional chemical disinfection may be required to mitigate biofouling and will typically consist of H2O2 or NaOCl cleaning solutions. O&M considerations Monitoring and control required for flow rates, product water quality and resin regeneration. System will likely require minimal supervisory oversight. Level of flexibility: System is optimized to remove Na ions, but will achieve moderate removal of divalent cations and metals. Level of robustness: IX processes are highly sensitive to fouling from organic materials and suspended solids. Care should be exercised to limit exposure of IX resin to oxidized metals and sparingly soluble mineral salts. Acid cation resins should not be exposed to feed temperatures in excess of 120 °C. Level of reliability: No information is provided on system up time. Types of energy required: electrical. Overall costs No data provided. 110PDF Image | TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES

PDF Search Title:

TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIESOriginal File Name Searched:

Tech_Assessment_PW_Treatment_Tech.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |