PDF Publication Title:

Text from PDF Page: 124

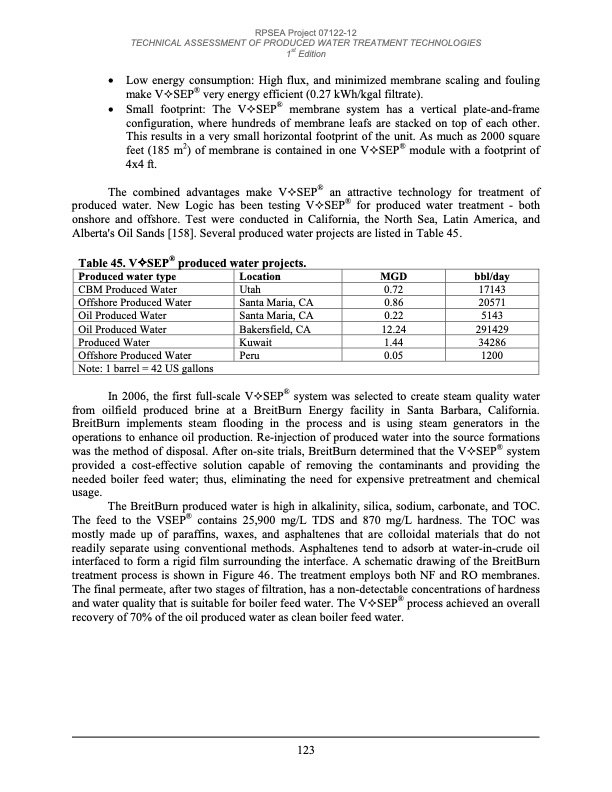

RPSEA Project 07122-12 TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES 1st Edition Low energy consumption: High flux, and minimized membrane scaling and fouling make VSEP® very energy efficient (0.27 kWh/kgal filtrate). Small footprint: The VSEP® membrane system has a vertical plate-and-frame configuration, where hundreds of membrane leafs are stacked on top of each other. This results in a very small horizontal footprint of the unit. As much as 2000 square feet (185 m2) of membrane is contained in one VSEP® module with a footprint of 4x4 ft. The combined advantages make VSEP® an attractive technology for treatment of produced water. New Logic has been testing VSEP® for produced water treatment - both onshore and offshore. Test were conducted in California, the North Sea, Latin America, and Alberta's Oil Sands [158]. Several produced water projects are listed in Table 45. Table 45. VSEP® produced water projects. Produced water type CBM Produced Water Offshore Produced Water Oil Produced Water Oil Produced Water Produced Water Offshore Produced Water Note: 1 barrel = 42 US gallons Location MGD bbl/day Utah 0.72 17143 Santa Maria, CA Santa Maria, CA Bakersfield, CA 0.86 20571 0.22 5143 12.24 291429 Kuwait 1.44 34286 Peru 0.05 1200 In 2006, the first full-scale VSEP® system was selected to create steam quality water from oilfield produced brine at a BreitBurn Energy facility in Santa Barbara, California. BreitBurn implements steam flooding in the process and is using steam generators in the operations to enhance oil production. Re-injection of produced water into the source formations was the method of disposal. After on-site trials, BreitBurn determined that the VSEP® system provided a cost-effective solution capable of removing the contaminants and providing the needed boiler feed water; thus, eliminating the need for expensive pretreatment and chemical usage. The BreitBurn produced water is high in alkalinity, silica, sodium, carbonate, and TOC. The feed to the VSEP® contains 25,900 mg/L TDS and 870 mg/L hardness. The TOC was mostly made up of paraffins, waxes, and asphaltenes that are colloidal materials that do not readily separate using conventional methods. Asphaltenes tend to adsorb at water-in-crude oil interfaced to form a rigid film surrounding the interface. A schematic drawing of the BreitBurn treatment process is shown in Figure 46. The treatment employs both NF and RO membranes. The final permeate, after two stages of filtration, has a non-detectable concentrations of hardness and water quality that is suitable for boiler feed water. The VSEP® process achieved an overall recovery of 70% of the oil produced water as clean boiler feed water. 123PDF Image | TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIES

PDF Search Title:

TECHNICAL ASSESSMENT OF PRODUCED WATER TREATMENT TECHNOLOGIESOriginal File Name Searched:

Tech_Assessment_PW_Treatment_Tech.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |