PDF Publication Title:

Text from PDF Page: 016

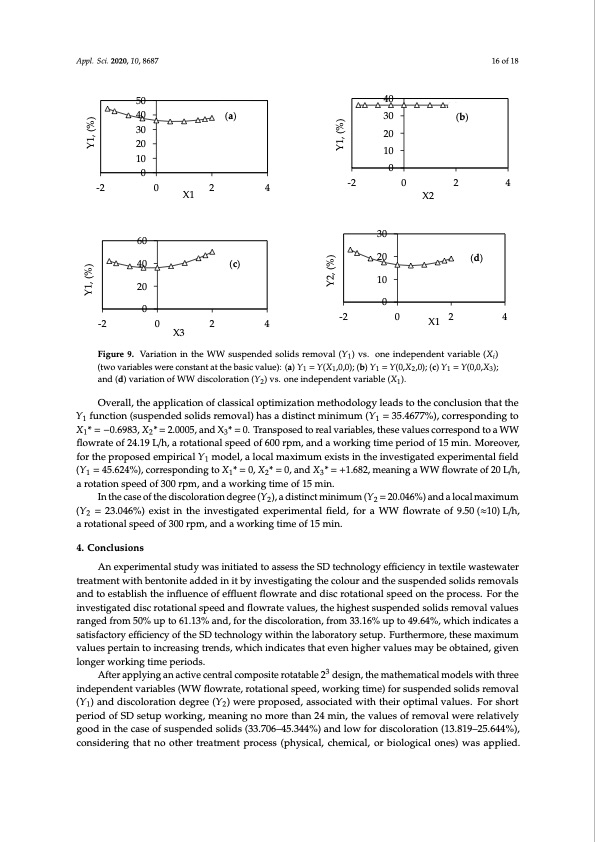

Appl. Sci. 2020, 10, x FOR PEER REVIEW 16 of 19 Appl. Sci. 2020, 10, 8687 16 of 18 50 40 30 20 10 0 ‐2 0X12 4 (a) 40 30 20 10 0 ‐2 0 2 4 X2 (b) 60 40 20 0 ‐2 0 2 4 X3 (c) 30 20 10 0 ‐2 0 X12 4 (d) Figure 9. Variation in the WW suspended solids removal (Y1) vs. one independent variable (Xi) Figur(etw9.oVvarriiatbiolensiwnetrheecWonWstasnutsaptetnhdeebdasioclvidaslure)m: (oav)aYl (Y=1Y) v(Xs. ,o0n,0e);in(bd)eYpen=dYen(0t,Xva,r0ia);b(lce)(YXi)=(tYw(0o,0,X ); variabalneds w(de)rveacroiantsitoanotfatWthWedbaiscioclvoaralutieo)n: ((aY) Y)1v=s.Yo(nXe1,i0n,0d)e;p(ben)dYe1n=tYv(a0r,iXa2b,0le);(X(c))Y. 1 = Y(0,0,X3); and 21 (d) variation of WW discoloration (Y2) vs. one independent variable (X1). Overall, the application of classical optimization methodology leads to the conclusion that the TYhefuvnacrtiaiotinon(suinsptheendsuedspseonldidesdrseomliodvsarle)mhaosvald(Yis1t)inwcittmh tinhieminucmrea(Yse i=nt3h5e.4W67W7%fl)o, wcorarteesp(Xo1n)dising to 11 obvioXus*i=nF−i0g.u69re839,aX.O*n=e2c.a0n00o5b,saenrdveXa*m=in0.imTruamnsopfosuedspteonrdeaeldvsaorliiadbslerse,mthoevsaelv(aYl1u=es35co.4r6r7es%p)ofnodrtXo1*aWW 123 =0.69fl8o4warnadteaolfo2c4a.l19mLa/xhim,aurmota(Ytio1=na4l4s.3p5e1e%d)ofo6r00arWpmW,falnodwarawteoorkfi2n4g.1t9imLe/hp,eariroodtaotfio1n5amlsipn.eeMdoorfeover, 300 rpfomr,thaendpraopwoosrekdinegmtpimiriecainltYervmalodofel1,5amloicna.lTmhaexdimepuemndeexnisctesoinf thesinuvspesetnigdaetdedsoelxidpseriemeonvtalfield 4. Conclusions 1 * (Y1)o(nYth=e4ro5t.6a2ti4o%na),lcsopreredsp(oXn2d)ingditcoaXtes*a=c0o,nXsta*n=tv0a,aluned(XY1*==36+.19.608%2),mfoeranllinXg2avWaluWesfl(oFwigruarteo9bf)2.0L/h, 1123 The vaaroiatatitoionnisnpYe1ewdiothf 3a0n0 rinpcmre,asnedianwthoerkwinogrktimnge toifm1e5 (mXi3n).indicates a minimum removal (Y1 = 36.777%) fIonrthXe3*ca=se+0o.f2t6h5e9d(iasclolcoarlamtioinidmeugrmeef(oYr a),falodwisrtiantcetomfi2n0imLu/hm, a(Yro=ta2ti0o.0n4a6l%sp)eaendoaflo3c0a0lmrpamxi,mum 22 and a(nY op=er2a3t.i0n4g6t%im) exoifs1t 6i.n33thmeinin(vFeigstuigreat9ecd). experimental field, for a WW flowrate of 9.50 (≈10) L/h, 2 Oanroetacatinonoablsseprveedthoefe3x0i0strepnmce,aonfdamawinoimrkuinmgdtiimsceolofr1a5tiomnind.egree(Y2=16.054%)forX1*=0.5025 and also of a local maximum (Y2 = 23.046%) for X1* = −1.75 in the investigated experimental field. Overall, the application of classical optimization methodology leads to the conclusion that the Y1 function (suspended solids removal) has a distinct minimum (Y1 = 35.4677%), corresponding to X1* An experimental study was initiated to assess the SD technology efficiency in textile wastewater = −0.6983, X2* = 2.0005, and X3* = 0. Transposed to real variables, these values correspond to a WW treatment with bentonite added in it by investigating the colour and the suspended solids removals flowrate of 24.19 L/h, a rotational speed of 600 rpm, and a working time period of 15 min. Moreover, and to establish the influence of effluent flowrate and disc rotational speed on the process. For the for the proposed empirical Y1 model, a local maximum exists in the investigated experimental field investigated disc rotational speed and flowrate values, the highest suspended solids removal values (Y1 = 45.624%), corresponding to X1* = 0, X2* = 0, and X3* = +1.682, meaning a WW flowrate of 20 L/h, ranged from 50% up to 61.13% and, for the discoloration, from 33.16% up to 49.64%, which indicates a a rotation speed of 300 rpm, and a working time of 15 min. satisfactory efficiency of the SD technology within the laboratory setup. Furthermore, these maximum In the case of the discoloration degree (Y2), a distinct minimum (Y2 = 20.046%) and a local values pertain to increasing trends, which indicates that even higher values may be obtained, given maximum (Y2 = 23.046%) exist in the investigated experimental field, for a WW flowrate of 9.50 (≈10) longer working time periods. L/h, a rotational speed of 300 rpm, and a working time of 15 min. After applying an active central composite rotatable 23 design, the mathematical models with three independent variables (WW flowrate, rotational speed, working time) for suspended solids removal 4. Conclusions (Y1) and discoloration degree (Y2) were proposed, associated with their optimal values. For short period of SD setup working, meaning no more than 24 min, the values of removal were relatively An experimental study was initiated to assess the SD technology efficiency in textile wastewater good in the case of suspended solids (33.706–45.344%) and low for discoloration (13.819–25.644%), treatment with bentonite added in it by investigating the colour and the suspended solids removals considering that no other treatment process (physical, chemical, or biological ones) was applied. and to establish the influence of effluent flowrate and disc rotational speed on the process. For the investigated disc rotational speed and flowrate values, the highest suspended solids removal values ranged from 50% up to 61.13% and, for the discoloration, from 33.16% up to 49.64%, which indicates 111213 Y1, (%) Y1, (%) Y2, (%) Y1, (%)PDF Image | Textile Wastewater Treatment on a Spinning Disc Reactor

PDF Search Title:

Textile Wastewater Treatment on a Spinning Disc ReactorOriginal File Name Searched:

applsci-10-08687.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |