PDF Publication Title:

Text from PDF Page: 008

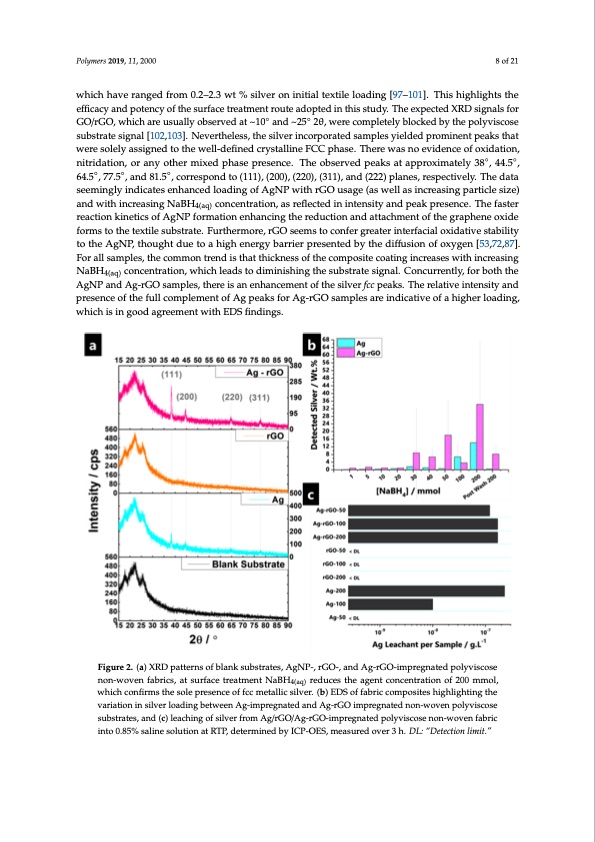

Polymers 2019, 11, 2000 8 of 21 which have ranged from 0.2–2.3 wt % silver on initial textile loading [97–101]. This highlights the efficacy and potency of the surface treatment route adopted in this study. The expected XRD signals for GO/rGO, which are usually observed at ~10◦ and ~25◦ 2θ, were completely blocked by the polyviscose substrate signal [102,103]. Nevertheless, the silver incorporated samples yielded prominent peaks that were solely assigned to the well-defined crystalline FCC phase. There was no evidence of oxidation, nitridation, or any other mixed phase presence. The observed peaks at approximately 38◦, 44.5◦, Polymers 2019, 11, 2000 8 of 21 64.5◦, 77.5◦, and 81.5◦, correspond to (111), (200), (220), (311), and (222) planes, respectively. The data sepelmaninesg,lyreisnpdeicctaivtelsye.nThaendceadtalsoeaedmininggolyf AingdNicPatwesitehnrhGanOceudsalogaed(iansgwoeflAl agsNinPcwreiathsinrGgOpaurstiacgle s(iazse) anwdewlliatshininccrreeaassininggpNaratiBcHlesize)coandcewntirthatinocnr,easirnegflNecateBdHi4n(aqi)nctoencseintytrantidonp,eaaskrepfrlecsteendcein.Tinhtenfsaisttyer 4(aq) reancdtiopneakkinpetriecseonfceA.gTNhePfaosrtmeratrieoancteionnhaknincientgicsthoefrAedguNcPtiofonramnadtiaotntaecnhhmaenncitnogfthegreradpuhcteinoneoaxnide foartmtaschtomtehnettoefxtihlesgurbapsthreante.oFxuirdteheformrmosret,orGthOetsexetmilesstoubcsotnrafeter.gFrueratheerrimntoerefa,crGiaOlosxeidematsivteosctoanbfielirty togtrheaetAergiNntPe,rftahcoiaulgohxtidautievteostaabhilgithy etonethrgeyAbgaNrrPi,etrhpouregshetndteude tboyathiegdhieffnuesrigoynboafrroixerygperense[5n3te,7d2b,8y7]. the diffusion of oxygen [53,72,87]. For all samples, the common trend is that thickness of the For all samples, the common trend is that thickness of the composite coating increases with increasing composite coating increases with increasing NaBH4(aq) concentration, which leads to diminishing the NaBH4(aq) concentration, which leads to diminishing the substrate signal. Concurrently, for both the substrate signal. Concurrently, for both the AgNP and Ag-rGO samples, there is an enhancement of AgNP and Ag-rGO samples, there is an enhancement of the silver fcc peaks. The relative intensity and the silver fcc peaks. The relative intensity and presence of the full complement of Ag peaks for Ag- presence of the full complement of Ag peaks for Ag-rGO samples are indicative of a higher loading, rGO samples are indicative of a higher loading, which is in good agreement with EDS findings. which is in good agreement with EDS findings. Figure 2. (a) XRD patterns of blank substrates, AgNP-, rGO-, and Ag-rGO-impregnated polyviscose Figure 2. (a) XRD patterns of blank substrates, AgNP-, rGO-, and Ag-rGO-impregnated polyviscose non-woven fabrics, at surface treatment NaBH4(aq) reduces the agent concentration of 200 mmol, non-woven fabrics, at surface treatment NaBH4(aq) reduces the agent concentration of 200 mmol, which which confirms the sole presence of fcc metallic silver. (b) EDS of fabric composites highlighting the confirms the sole presence of fcc metallic silver. (b) EDS of fabric composites highlighting the variation in silver loading between Ag-impregnated and Ag-rGO impregnated non-woven polyviscose variation in silver loading between Ag-impregnated and Ag-rGO impregnated non-woven substrates, and (c) leaching of silver from Ag/rGO/Ag-rGO-impregnated polyviscose non-woven fabric polyviscose substrates, and c) leaching of silver from Ag/rGO/Ag-rGO-impregnated polyviscose non- into 0.85% saline solution at RTP, determined by ICP-OES, measured over 3 h. DL: “Detection limit.” woven fabric into 0.85% saline solution at RTP, determined by ICP-OES, measured over 3 h. DL: “Detection limit.” ICP-OES data on leaching studies (ICP-OES provides elemental specificity and high sensitivity – limits of detection in the μg/L range) was used to determine the extent of Ag-species leaching from the polyviscose substrate into the solution (Figure 2c). Use of rGO as an overlay/protective coating allowed for effective adhesion and durability of AgNP, which minimised the aggregation problem of AgNPs and allows higher overall loadings of silver to be achieved, all with long-term protection capability [59]. In both the solely AgNP and Ag-rGO samples, there was a detectable leaching of silverPDF Image | Antimicrobial from Silver-Graphene Coated Medical Textiles

PDF Search Title:

Antimicrobial from Silver-Graphene Coated Medical TextilesOriginal File Name Searched:

polymers-11-02000-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |