PDF Publication Title:

Text from PDF Page: 004

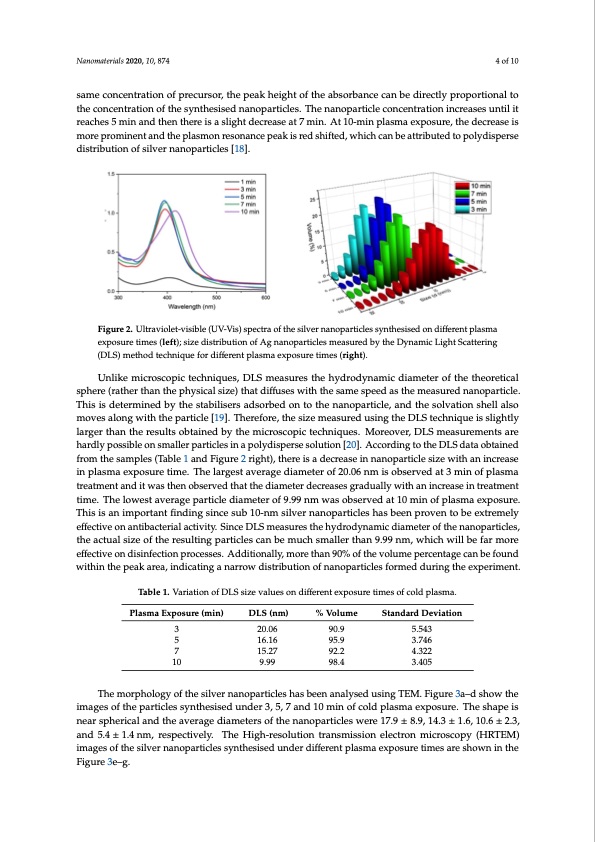

The colour of the precursor solution changed to yellow after a few minutes of the plasma treatment, indicating the formation of the nanoparticles. All the samples present the characteristic surface plasmon resonance peak of silver nanoparticles (Figure 2). A slight but significant peak was observable for 1 min of plasma exposure, but this later became more prominent. The width of the Nanomaterials 2020, 10, 874 4 of 10 each plasmon is related to the size distribution of the nanoparticles. The 3‐min, 5‐min and 7‐min samples produced peaks at 369 nm, 394 nm and 396 nm, respectively. The 1‐min and 10‐min samples have their surface plasmon peaks at 404 nm and 416 nm, respectively. Since equal volumes of samples same concentration of precursor, the peak height of the absorbance can be directly proportional to reacted using the same concentration of precursor, the peak height of the absorbance can be directly the concentration of the synthesised nanoparticles. The nanoparticle concentration increases until it proportional to the concentration of the synthesised nanoparticles. The nanoparticle concentration reaches 5 min and then there is a slight decrease at 7 min. At 10-min plasma exposure, the decrease is increases until it reaches 5 min and then there is a slight decrease at 7 min. At 10‐min plasma more prominent and the plasmon resonance peak is red shifted, which can be attributed to polydisperse exposure, the decrease is more prominent and the plasmon resonance peak is red shifted, which can distribution of silver nanoparticles [18]. be attributed to polydisperse distribution of silver nanoparticles [18]. Figure2. Ultraviolet‐-visible(UV-‐Vis)sspeeccttrraooffththeesilsvilevrenranaonpoapratirctlieclsesysnytnhtehseiseisdedonodniffdeirffeenrtepntlasma pexlapsomsuarextpiomseusre(lteifmt)e;ssi(zleftd);istirziebudtiisotrnibouftAiognnoafnAogpanratnicolpesarmticelaesumreedasbuyrethdebDyythneamDiycnLaimghictLSicgahttering Scattering (DLS) method technique for different plasma exposure times (right). (DLS) method technique for different plasma exposure times (right). Unlikemiiccrroossccooppicictetcehcnhinqiuqeuse,sD,LDSLmSemaseuarseusrethsetheydhryodryondaymniacmdicamdieatemreotferthoeftheortheteicoarletical sphere (rather than the physical size) that diffuses with the same speed as the measured nanoparticle. sphere (rather than the physical size) that diffuses with the same speed as the measured nanoparticle. This is determined by the stabilisers adsorbed on to the nanoparticle, and the solvation shell also This is determined by the stabilisers adsorbed on to the nanoparticle, and the solvation shell also moves along with the particle [19]. Therefore, the size measured using the DLS technique is slightly moves along with the particle [19]. Therefore, the size measured using the DLS technique is slightly larger than the results obtained by the microscopic techniques. Moreover, DLS measurements are larger than the results obtained by the microscopic techniques. Moreover, DLS measurements are hardly possible on smaller particles in a polydisperse solution [20]. According to the DLS data hardly possible on smaller particles in a polydisperse solution [20]. According to the DLS data obtained obtained from the samples (Table 1 and Figure 2 right), there is a decrease in nanoparticle size with from the samples (Table 1 and Figure 2 right), there is a decrease in nanoparticle size with an increase an increase in plasma exposure time. The largest average diameter of 20.06 nm is observed at 3 min in plasma exposure time. The largest average diameter of 20.06 nm is observed at 3 min of plasma of plasma treatment and it was then observed that the diameter decreases gradually with an increase treatment and it was then observed that the diameter decreases gradually with an increase in treatment in treatment time. The lowest average particle diameter of 9.99 nm was observed at 10 min of plasma time. The lowest average particle diameter of 9.99 nm was observed at 10 min of plasma exposure. exposure. This is an important finding since sub 10‐nm silver nanoparticles has been proven to be This is an important finding since sub 10-nm silver nanoparticles has been proven to be extremely extremely effective on antibacterial activity. Since DLS measures the hydrodynamic diameter of the effective on antibacterial activity. Since DLS measures the hydrodynamic diameter of the nanoparticles, nanoparticles, the actual size of the resulting particles can be much smaller than 9.99 nm, which will the actual size of the resulting particles can be much smaller than 9.99 nm, which will be far more be far more effective on disinfection processes. Additionally, more than 90% of the volume effective on disinfection processes. Additionally, more than 90% of the volume percentage can be found percentage can be found within the peak area, indicating a narrow distribution of nanoparticles within the peak area, indicating a narrow distribution of nanoparticles formed during the experiment. formed during the experiment. Table 1. Variation of DLS size values on different exposure times of cold plasma. Table 1. Variation of DLS size values on different exposure times of cold plasma. Plasma Exposure (min) % Volume 20.06 90.9 Standard DSteavniadtaiordn Plasma Exposure (min) DLS (nm) % Volume 3 5 7 20.06 90.9 5.543 DLS (nm) Deviation 3 5 7 10 5.543 16.16 95.9 15.2716.16 92.2 95.9 3.746 9.99 98.4 3.405 15.27 92.2 4.322 4.3223.746 The morphology of the silver nanoparticles has been analysed using TEM. Figure 3a–d show the images of the particles synthesised under 3, 5, 7 and 10 min of cold plasma exposure. The shape is near spherical and the average diameters of the nanoparticles were 17.9 ± 8.9, 14.3 ± 1.6, 10.6 ± 2.3, and 5.4 ± 1.4 nm, respectively. The High-resolution transmission electron microscopy (HRTEM) images of the silver nanoparticles synthesised under different plasma exposure times are shown in the Figure 3e–g.PDF Image | Bactericidal Silver Nanoparticles by Plasma Processing

PDF Search Title:

Bactericidal Silver Nanoparticles by Plasma ProcessingOriginal File Name Searched:

nanomaterials-10-00874.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |