PDF Publication Title:

Text from PDF Page: 010

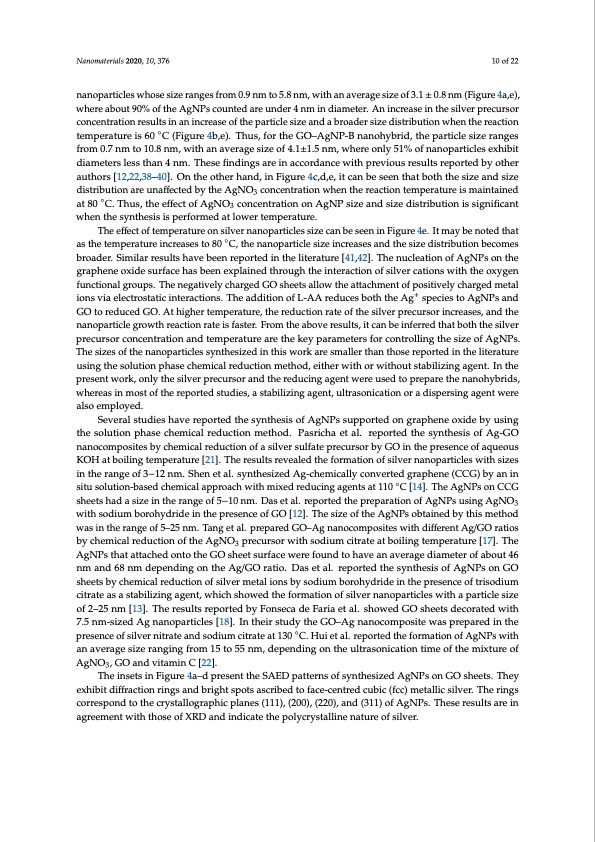

Nanomaterials 2020, 10, 376 10 of 22 nanoparticles whose size ranges from 0.9 nm to 5.8 nm, with an average size of 3.1 ± 0.8 nm (Figure 4a,e), where about 90% of the AgNPs counted are under 4 nm in diameter. An increase in the silver precursor concentration results in an increase of the particle size and a broader size distribution when the reaction temperature is 60 ◦C (Figure 4b,e). Thus, for the GO–AgNP-B nanohybrid, the particle size ranges from 0.7 nm to 10.8 nm, with an average size of 4.1±1.5 nm, where only 51% of nanoparticles exhibit diameters less than 4 nm. These findings are in accordance with previous results reported by other authors [12,22,38–40]. On the other hand, in Figure 4c,d,e, it can be seen that both the size and size distribution are unaffected by the AgNO3 concentration when the reaction temperature is maintained at 80 ◦C. Thus, the effect of AgNO3 concentration on AgNP size and size distribution is significant when the synthesis is performed at lower temperature. The effect of temperature on silver nanoparticles size can be seen in Figure 4e. It may be noted that as the temperature increases to 80 ◦C, the nanoparticle size increases and the size distribution becomes broader. Similar results have been reported in the literature [41,42]. The nucleation of AgNPs on the graphene oxide surface has been explained through the interaction of silver cations with the oxygen functional groups. The negatively charged GO sheets allow the attachment of positively charged metal ions via electrostatic interactions. The addition of L-AA reduces both the Ag+ species to AgNPs and GO to reduced GO. At higher temperature, the reduction rate of the silver precursor increases, and the nanoparticle growth reaction rate is faster. From the above results, it can be inferred that both the silver precursor concentration and temperature are the key parameters for controlling the size of AgNPs. The sizes of the nanoparticles synthesized in this work are smaller than those reported in the literature using the solution phase chemical reduction method, either with or without stabilizing agent. In the present work, only the silver precursor and the reducing agent were used to prepare the nanohybrids, whereas in most of the reported studies, a stabilizing agent, ultrasonication or a dispersing agent were also employed. Several studies have reported the synthesis of AgNPs supported on graphene oxide by using the solution phase chemical reduction method. Pasricha et al. reported the synthesis of Ag-GO nanocomposites by chemical reduction of a silver sulfate precursor by GO in the presence of aqueous KOH at boiling temperature [21]. The results revealed the formation of silver nanoparticles with sizes in the range of 3−12 nm. Shen et al. synthesized Ag-chemically converted graphene (CCG) by an in situ solution-based chemical approach with mixed reducing agents at 110 ◦C [14]. The AgNPs on CCG sheets had a size in the range of 5−10 nm. Das et al. reported the preparation of AgNPs using AgNO3 with sodium borohydride in the presence of GO [12]. The size of the AgNPs obtained by this method was in the range of 5–25 nm. Tang et al. prepared GO–Ag nanocomposites with different Ag/GO ratios by chemical reduction of the AgNO3 precursor with sodium citrate at boiling temperature [17]. The AgNPs that attached onto the GO sheet surface were found to have an average diameter of about 46 nm and 68 nm depending on the Ag/GO ratio. Das et al. reported the synthesis of AgNPs on GO sheets by chemical reduction of silver metal ions by sodium borohydride in the presence of trisodium citrate as a stabilizing agent, which showed the formation of silver nanoparticles with a particle size of 2–25 nm [13]. The results reported by Fonseca de Faria et al. showed GO sheets decorated with 7.5 nm-sized Ag nanoparticles [18]. In their study the GO–Ag nanocomposite was prepared in the presence of silver nitrate and sodium citrate at 130 ◦C. Hui et al. reported the formation of AgNPs with an average size ranging from 15 to 55 nm, depending on the ultrasonication time of the mixture of AgNO3, GO and vitamin C [22]. The insets in Figure 4a–d present the SAED patterns of synthesized AgNPs on GO sheets. They exhibit diffraction rings and bright spots ascribed to face-centred cubic (fcc) metallic silver. The rings correspond to the crystallographic planes (111), (200), (220), and (311) of AgNPs. These results are in agreement with those of XRD and indicate the polycrystalline nature of silver.PDF Image | Graphene Oxide–Silver Nanoparticle Nanohybrids

PDF Search Title:

Graphene Oxide–Silver Nanoparticle NanohybridsOriginal File Name Searched:

nanomaterials-10-00376.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |