PDF Publication Title:

Text from PDF Page: 005

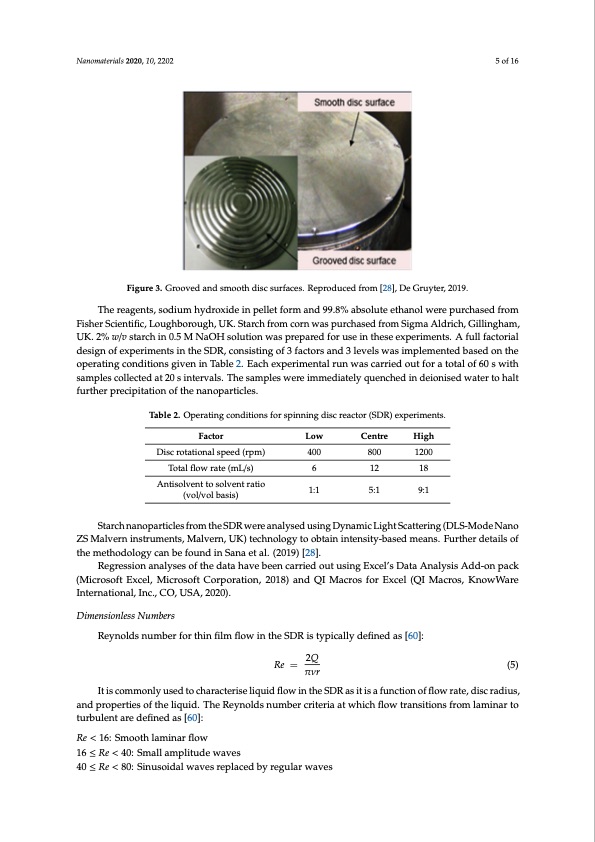

Nanomaterials 2020, 10, 2202 5 of 16 Figure 3. Grooved and smooth disc surfaces. Reproduced from [28], De Gruyter, 2019. The reagents, sodium hydroxide in pellet form and 99.8% absolute ethanol were purchased from Fisher Scientific, Loughborough, UK. Starch from corn was purchased from Sigma Aldrich, Gillingham, UK. 2% w/v starch in 0.5 M NaOH solution was prepared for use in these experiments. A full factorial design of experiments in the SDR, consisting of 3 factors and 3 levels was implemented based on the operating conditions given in Table 2. Each experimental run was carried out for a total of 60 s with samples collected at 20 s intervals. The samples were immediately quenched in deionised water to halt further precipitation of the nanoparticles. Table 2. Operating conditions for spinning disc reactor (SDR) experiments. Factor Disc rotational speed (rpm) Total flow rate (mL/s) Antisolvent to solvent ratio (vol/vol basis) Low Centre High 400 800 1200 6 12 18 1:1 5:1 9:1 Starch nanoparticles from the SDR were analysed using Dynamic Light Scattering (DLS-Mode Nano ZS Malvern instruments, Malvern, UK) technology to obtain intensity-based means. Further details of the methodology can be found in Sana et al. (2019) [28]. Regression analyses of the data have been carried out using Excel’s Data Analysis Add-on pack (Microsoft Excel, Microsoft Corporation, 2018) and QI Macros for Excel (QI Macros, KnowWare International, Inc., CO, USA, 2020). Dimensionless Numbers Reynolds number for thin film flow in the SDR is typically defined as [60]: Re = 2Q (5) πνr It is commonly used to characterise liquid flow in the SDR as it is a function of flow rate, disc radius, and properties of the liquid. The Reynolds number criteria at which flow transitions from laminar to turbulent are defined as [60]: Re < 16: Smooth laminar flow 16 ≤ Re < 40: Small amplitude waves 40 ≤ Re < 80: Sinusoidal waves replaced by regular wavesPDF Image | Hydro Starch Nanoparticles Precip Spinning Disc Reactor

PDF Search Title:

Hydro Starch Nanoparticles Precip Spinning Disc ReactorOriginal File Name Searched:

nanomaterials-10-02202-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |