PDF Publication Title:

Text from PDF Page: 007

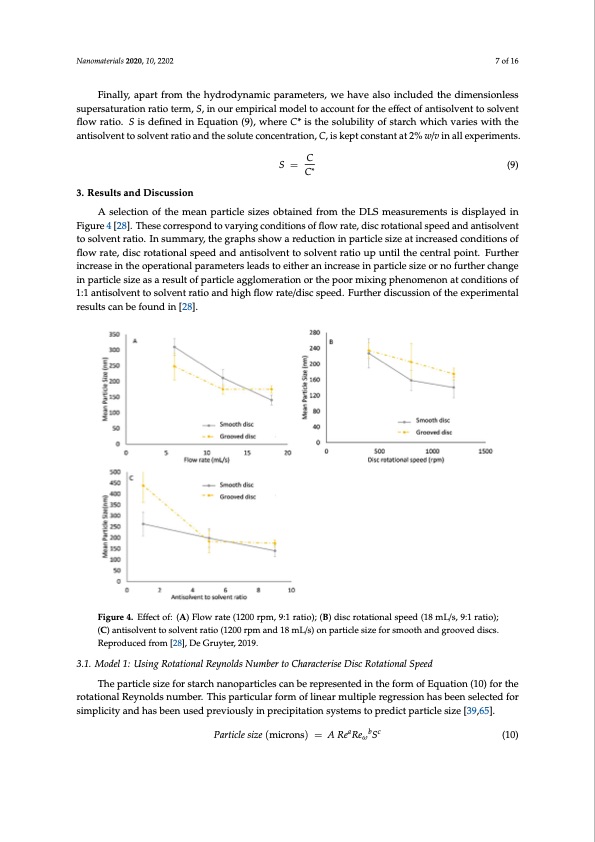

Nanomaterials 2020, 10, 2202 7 of 16 Finally, apart from the hydrodynamic parameters, we have also included the dimensionless supersaturation ratio term, S, in our empirical model to account for the effect of antisolvent to solvent flow ratio. S is defined in Equation (9), where C* is the solubility of starch which varies with the antisolvent to solvent ratio and the solute concentration, C, is kept constant at 2% w/v in all experiments. S=C (9) C∗ 3. Results and Discussion A selection of the mean particle sizes obtained from the DLS measurements is displayed in Figure 4 [28]. These correspond to varying conditions of flow rate, disc rotational speed and antisolvent to solvent ratio. In summary, the graphs show a reduction in particle size at increased conditions of flow rate, disc rotational speed and antisolvent to solvent ratio up until the central point. Further increase in the operational parameters leads to either an increase in particle size or no further change in particle size as a result of particle agglomeration or the poor mixing phenomenon at conditions of 1:1 antisolvent to solvent ratio and high flow rate/disc speed. Further discussion of the experimental results can be found in [28]. Figure 4. Effect of: (A) Flow rate (1200 rpm, 9:1 ratio); (B) disc rotational speed (18 mL/s, 9:1 ratio); (C) antisolvent to solvent ratio (1200 rpm and 18 mL/s) on particle size for smooth and grooved discs. Reproduced from [28], De Gruyter, 2019. 3.1. Model 1: Using Rotational Reynolds Number to Characterise Disc Rotational Speed The particle size for starch nanoparticles can be represented in the form of Equation (10) for the rotational Reynolds number. This particular form of linear multiple regression has been selected for simplicity and has been used previously in precipitation systems to predict particle size [39,65]. Particle size (microns) = A ReaReωbSc (10)PDF Image | Hydro Starch Nanoparticles Precip Spinning Disc Reactor

PDF Search Title:

Hydro Starch Nanoparticles Precip Spinning Disc ReactorOriginal File Name Searched:

nanomaterials-10-02202-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |