PDF Publication Title:

Text from PDF Page: 011

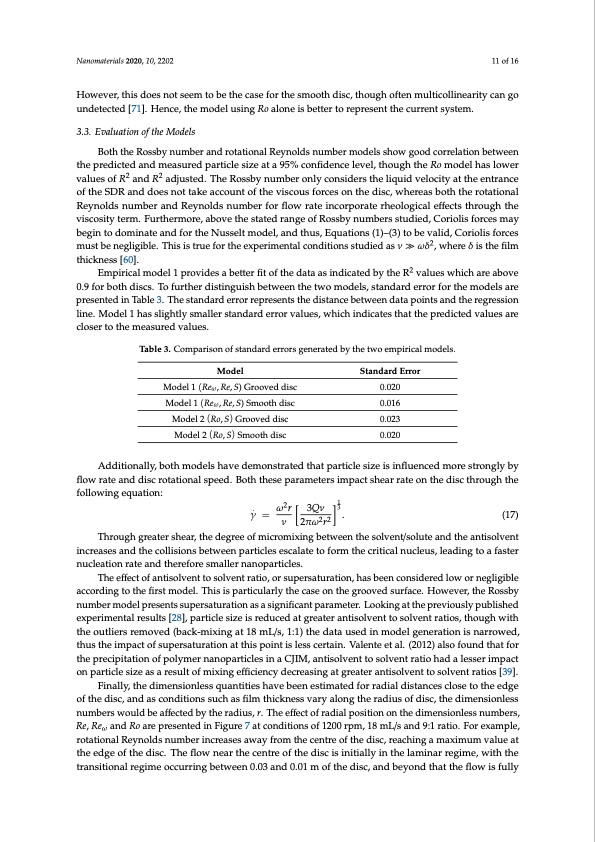

Nanomaterials 2020, 10, 2202 11 of 16 However, this does not seem to be the case for the smooth disc, though often multicollinearity can go undetected [71]. Hence, the model using Ro alone is better to represent the current system. 3.3. Evaluation of the Models Both the Rossby number and rotational Reynolds number models show good correlation between the predicted and measured particle size at a 95% confidence level, though the Ro model has lower values of R2 and R2 adjusted. The Rossby number only considers the liquid velocity at the entrance of the SDR and does not take account of the viscous forces on the disc, whereas both the rotational Reynolds number and Reynolds number for flow rate incorporate rheological effects through the viscosity term. Furthermore, above the stated range of Rossby numbers studied, Coriolis forces may begin to dominate and for the Nusselt model, and thus, Equations (1)–(3) to be valid, Coriolis forces must be negligible. This is true for the experimental conditions studied as ν ≫ ωδ2, where δ is the film thickness [60]. Empirical model 1 provides a better fit of the data as indicated by the R2 values which are above 0.9 for both discs. To further distinguish between the two models, standard error for the models are presented in Table 3. The standard error represents the distance between data points and the regression line. Model 1 has slightly smaller standard error values, which indicates that the predicted values are closer to the measured values. Table 3. Comparison of standard errors generated by the two empirical models. Model Model 1 (Reω, Re, S) Grooved disc Model 1 (Reω, Re, S) Smooth disc Model 2 (Ro, S) Grooved disc Model 2 (Ro, S) Smooth disc Standard Error 0.020 0.016 0.023 0.020 Additionally, both models have demonstrated that particle size is influenced more strongly by flow rate and disc rotational speed. Both these parameters impact shear rate on the disc through the following equation: γ. = ω2r 3Qν 13. (17) ν 2πω2 r2 Through greater shear, the degree of micromixing between the solvent/solute and the antisolvent increases and the collisions between particles escalate to form the critical nucleus, leading to a faster nucleation rate and therefore smaller nanoparticles. The effect of antisolvent to solvent ratio, or supersaturation, has been considered low or negligible according to the first model. This is particularly the case on the grooved surface. However, the Rossby number model presents supersaturation as a significant parameter. Looking at the previously published experimental results [28], particle size is reduced at greater antisolvent to solvent ratios, though with the outliers removed (back-mixing at 18 mL/s, 1:1) the data used in model generation is narrowed, thus the impact of supersaturation at this point is less certain. Valente et al. (2012) also found that for the precipitation of polymer nanoparticles in a CJIM, antisolvent to solvent ratio had a lesser impact on particle size as a result of mixing efficiency decreasing at greater antisolvent to solvent ratios [39]. Finally, the dimensionless quantities have been estimated for radial distances close to the edge of the disc, and as conditions such as film thickness vary along the radius of disc, the dimensionless numbers would be affected by the radius, r. The effect of radial position on the dimensionless numbers, Re, Reω and Ro are presented in Figure 7 at conditions of 1200 rpm, 18 mL/s and 9:1 ratio. For example, rotational Reynolds number increases away from the centre of the disc, reaching a maximum value at the edge of the disc. The flow near the centre of the disc is initially in the laminar regime, with the transitional regime occurring between 0.03 and 0.01 m of the disc, and beyond that the flow is fullyPDF Image | Hydro Starch Nanoparticles Precip Spinning Disc Reactor

PDF Search Title:

Hydro Starch Nanoparticles Precip Spinning Disc ReactorOriginal File Name Searched:

nanomaterials-10-02202-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |