PDF Publication Title:

Text from PDF Page: 006

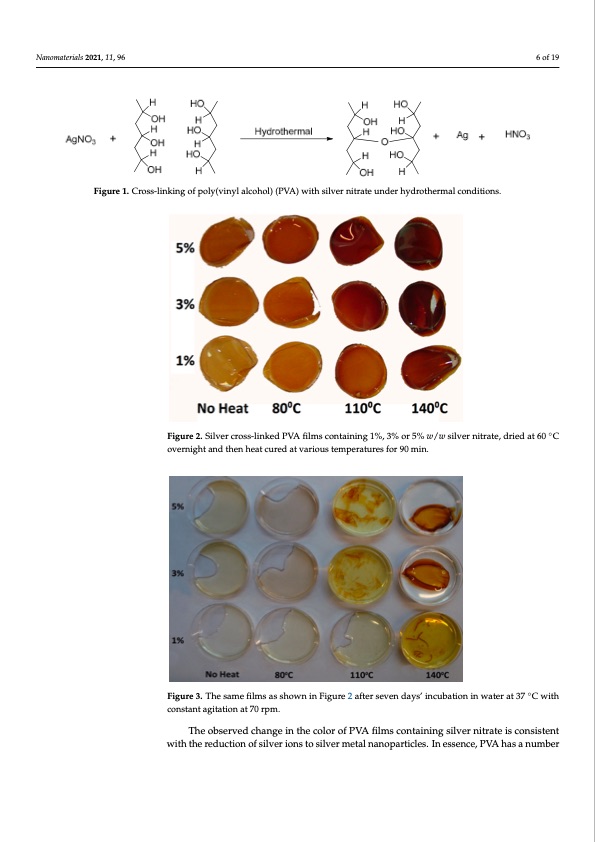

Nanomaterials 2021, 11, 96 Nanomaterials 2021, 11, x FOR PEER REVIEW Nanomaterials 2021, 11, x FOR PEER REVIEW Figure 1. Cross-linking of poly(vinyl alcohol) (PVA) with silver nitrate under hydrothermal conditions. Figure 1. Cross-linking of poly(vinyl alcohol) (PVA) with silver nitrate under hydrothermall condiittiions.. Figure 1. Cross-linking of poly(vinyl alcohol) (PVA) with silver nitrate under hydrothermal conditions. 6 of 19 6 of 20 6 of 20 Figure 2. Silver cross-linked PVA films containing 1%, 3% or 5% w/w silver nitrate, dried at 60 °C overnight and then heat cured at various temperatures for 90 min. The appearance of the same films after immersion in water and constant agitation for one week at 37 °C in an incubator shaker is shown in Figure 3. The films that had only been dried and the films dried and heat cured at 80 °C for 90 min dissolved rapidly in water; however, the films heat cured at 110 °C for 90 min were only partly dissolved after Figure 2. Silver cross-linked PVA films containing 1%, 3% or 5% w/w silver nitrate, dried at 60 °C Foingeurwe e2e. kSilavnerdctrhoses-flilnmkesdhPeVatAcfuilrmesdcaotnt1a4in0i°nCg 1f%or, 39%0 omr i5n%awpp/weasrilevdertnoitreamte,adinrieidntatc6t.0 T°◦Che Figure 2. Silver cross-linked PVA films containing 1%, 3% or 5% w/w silver nitrate, dried at 60 C overnight and then heat cured at various temperatures for 90 min. aovqeurenoiguhst laenadchthaeten fhreoamt cuthredfialtmvsartioouks toenmapeyreatlulorwes fcorlo90urm, iwn.hich was particularly noticea- overnight and then heat cured at various temperatures for 90 min. ble for the films that showed some degree of dissolution in water. The appearance of the same films after immersion in water and constant agitation for The appearance of the same films after immersion in water and constant agitation for one week at 37 °C in an incubator shaker is shown in Figure 3. The films that had only one week at 37 °C in an incubator shaker is shown in Figure 3. The films that had only been dried and the films dried and heat cured at 80 °C for 90 min dissolved rapidly in been dried and the films dried and heat cured at 80 °C for 90 min dissolved rapidly in water; however, the films heat cured at 110 °C for 90 min were only partly dissolved after water; however, the films heat cured at 110 °C for 90 min were only partly dissolved after one week and the films heat cured at 140 °C for 90 min appeared to remain intact. The one week and the films heat cured at 140 °C for 90 min appeared to remain intact. The aqueous leachate from the films took on a yellow colour, which was particularly noticea- aqueous leachate from the films took on a yellow colour, which was particularly noticea- ble for the films that showed some degree of dissolution in water. ble for the films that showed some degree of dissolution in water. Figure 3. The same films as shown in Figure 2 after seven days’ incubation in water at 37 °◦C with Figure 3. The same films as shown in Figure 2 after seven days’ incubation in water at 37 C with constant agitation at 70 rpm. constant agitation at 70 rpm. The observed change in the color of PVA films containing silver nitrate is consistent with the reduction of silver ions to silver metal nanoparticles. In essence, PVA has a number Figure 3. The same films as shown in Figure 2 after seven days’ incubation in water at 37 °C with Figure 3. The same films as shown in Figure 2 after seven days’ incubation in water at 37 °C with constant agitation at 70 rpm. constant agitation at 70 rpm.PDF Image | Hydrogel Forming Dressings Containing Silver Nanoparticles

PDF Search Title:

Hydrogel Forming Dressings Containing Silver NanoparticlesOriginal File Name Searched:

nanomaterials-11-00096.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |