PDF Publication Title:

Text from PDF Page: 011

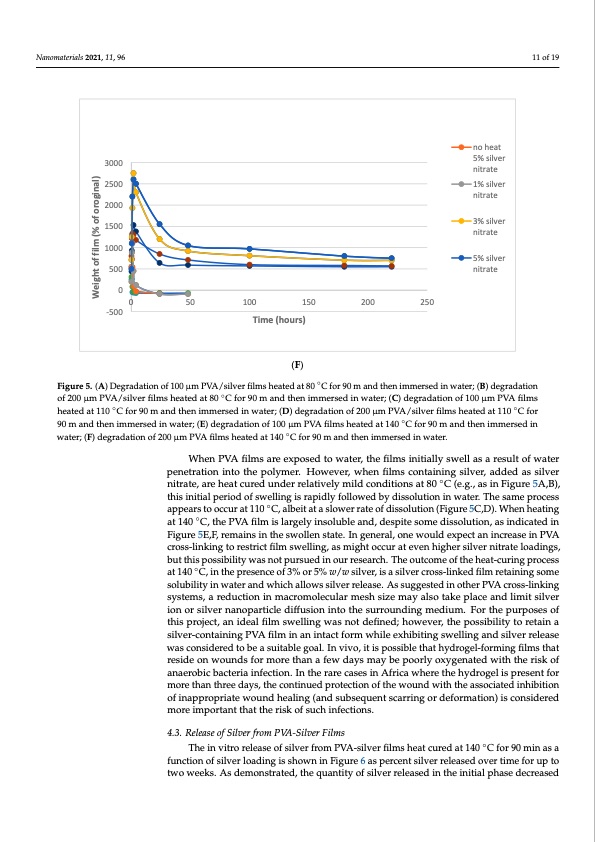

Nanomaterials 2021, 11, x FOR PEER REVIEW Nanomaterials 2021, 11, 96 11 of 20 (F) Figure 5. (A) Degradation of 100 μm PVA/silver films heated at 80 °◦C for 90 m and then immersed in water; (B) degradation Figure 5. (A) Degradation of 100 μm PVA/silver films heated at 80 C for 90 m and then immersed in water; (B) degradation of 200 μm PVA/silver films heated at 80 °◦C for 90 m and then immersed in water; (C) degradation of 100 μm PVA films of 200 μm PVA/silver films heated at 80 C for 90 m and then immersed in water; (C) degradation of 100 μm PVA films heated at 110 °C for 90 m and then immersed in water; (D) degradation of 200 μm PVA/silver films heated at 110 °C for heated at 110 ◦C for 90 m and then immersed in water; (D) degradation of 200 μm PVA/silver films heated at 110 ◦C for 90 m and then immersed in water; (E) degradation of 100 μm PVA films heated at 140 °C for 90 m and then immersed in 90 m and then immersed in water; (E) degradation of 100 μm PVA films heated at 140 ◦C for 90 m and then immersed in water; (F) degradation of 200 μm PVA films heated at 140 °C for 90 m and then immersed in water. water; (F) degradation of 200 μm PVA films heated at 140 ◦C for 90 m and then immersed in water. When PVA films are exposed to water, the films initially swell as a result of water 11 of 19 3000 2500 2000 1500 1000 500 0 0 50 100 150 200 250 no heat 5% silver nitrate 1% silver nitrate 3% silver nitrate 5% silver nitrate -500 Time (hours) When PVA films are exposed to water, the films initially swell as a result of water penetration into the polymer. However, when films containing silver, added as silver ni- penetration into the polymer. However, when films containing silver, added as silver trate, are heat cured under relatively mild conditions at 80 °C (◦e.g., as in Figure 5A,B), this nitrate, are heat cured under relatively mild conditions at 80 C (e.g., as in Figure 5A,B), initial period of swelling is rapidly followed by dissolution in water. The same process this initial period of swelling is rapidly followed by dissolution in water. The same process appears to occur at 110◦°C, albeit at a slower rate of dissolution (Figure 5C,D). When heat- appearstooccurat110 C,albeitataslowerrateofdissolution(Figure5C,D).Whenheating ing at 1◦40 °C, the PVA film is largely insoluble and, despite some dissolution, as indicated at 140 C, the PVA film is largely insoluble and, despite some dissolution, as indicated in in Figure 5E,F, remains in the swollen state. In general, one would expect an increase in Figure 5E,F, remains in the swollen state. In general, one would expect an increase in PVA PVA cross-linking to restrict film swelling, as might occur at even higher silver nitrate cross-linking to restrict film swelling, as might occur at even higher silver nitrate loadings, loadings, but this possibility was not pursued in our research. The outcome of the heat- but this possibility was not pursued in our research. The outcome of the heat-curing process curing◦process at 140 °C, in the presence of 3% or 5% w/w silver, is a silver cross-linked at140 C,inthepresenceof3%or5%w/wsilver,isasilvercross-linkedfilmretainingsome film retaining some solubility in water and which allows silver release. As suggested in solubility in water and which allows silver release. As suggested in other PVA cross-linking other PVA cross-linking systems, a reduction in macromolecular mesh size may also take systems, a reduction in macromolecular mesh size may also take place and limit silver place and limit silver ion or silver nanoparticle diffusion into the surrounding medium. ion or silver nanoparticle diffusion into the surrounding medium. For the purposes of For the purposes of this project, an ideal film swelling was not defined; however, the pos- this project, an ideal film swelling was not defined; however, the possibility to retain a sibility to retain a silver-containing PVA film in an intact form while exhibiting swelling silver-containing PVA film in an intact form while exhibiting swelling and silver release and silver release was considered to be a suitable goal. In vivo, it is possible that hydrogel- was considered to be a suitable goal. In vivo, it is possible that hydrogel-forming films that froersmidiengonfilwmosutnhdatsrfeosridmeorne wthoaunnadsfefwordmaoyrsemthaaynbaefpewoodrlayysoxmyagyenbaetpedoowrliythoxthyegernisakteodf wanitahertohbeircisbkacotfearniaeinrofebcitciobna.ctIenritaheinrfaerceticoans.eIsnitnheArfarirceacwasheesrientAhefrhicyadwrohgeerleitshperheysednrot gfoerl imsoprestehnatnftohrrmeeodraeytsh,atnhethcroenetidnauyesd,tphreotceocntitoinuoefdthperowtoecutniodnwoifththtehewaosusoncdiawteidthintheibaistison- coifaitnedapipnrhoipbritiiaotne wofouinadphperaolpinrigat(eanwdosunbdseqhueaelnint gsca(arnridngsuorbsdeeqfuoremntatsicoanr)rinsgcoonrsidefroerd- maotrieonim) ipsocrotannsitdtehraetdthmeorrisekimofpsourctahnitntfhecatiothnes.risk of such infections. 4.3. Release of Silver from PVA-Silver Films 4.3. Release of Silver from PVA-Silver Films The in vitro release of silver from PVA-silver films heat cured at 140 ◦C for 90 min as a The in vitro release of silver from PVA-silver films heat cured at 140 °C for 90 min as function of silver loading is shown in Figure 6 as percent silver released over time for up to a function of silver loading is shown in Figure 6 as percent silver released over time for two weeks. As demonstrated, the quantity of silver released in the initial phase decreased Weight of film (% of oroginal)PDF Image | Hydrogel Forming Dressings Containing Silver Nanoparticles

PDF Search Title:

Hydrogel Forming Dressings Containing Silver NanoparticlesOriginal File Name Searched:

nanomaterials-11-00096.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |