PDF Publication Title:

Text from PDF Page: 006

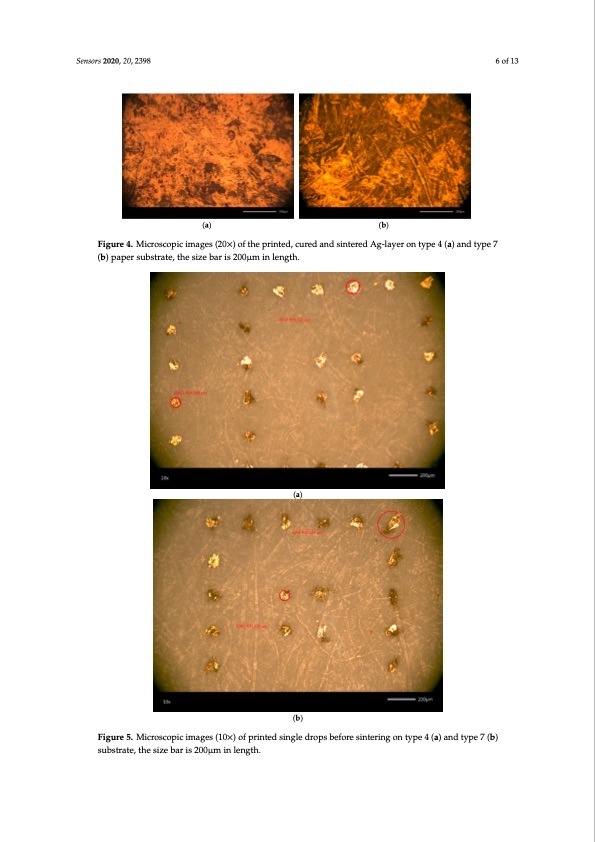

Sensors 2020, 20, 2398 Sensors 2020, 20, x 6 of 13 (b) paper substrate, the size bar is 200μm in length. Sensors 2020, 20, x 7 of 14 (a) (b) Figure 5. Microscopic images (10×) of printed single drops before sintering on type 4 (a) and type 7 (b) substrate, the size bar is 200μm in length. Microscopic images of the cross section perfectly illustrate the different nature of printed layers on non-porous PET substrate (Figure 6a) compared to the porous paper substrate (type 4, Figure 6b). While the Ag-layer on PET is quite homogeneous with an estimated thickness of 2.5 μm, the ink (a) obviously penetrates the fibres of the paper substrate. Hence, an estimation of the layer thickness is not trivial in this case. 6 of 13 (a) Figure 4. Microscopic images (20×) of the printed, cured and sintered Ag-layer on type 4 (a) and type Figure 4. Microscopic images (20×) of the printed, cured and sintered Ag-layer on type 4 (a) and type 7 7 (b) paper substrate, the size bar is 200μm in length. (b) (b) Figure 5. Microscopic images (10×) of printed single drops before sintering on type 4 (a) and type 7 Figure 5. Microscopic images (10×) of printed single drops before sintering on type 4 (a) and type 7 (b) (b) substrate, the size bar is 200μm in length. substrate, the size bar is 200μm in length. Microscopic images of the cross section perfectly illustrate the different nature of printed layers on non-porous PET substrate (Figure 6a) compared to the porous paper substrate (type 4, Figure 6b). While the Ag-layer on PET is quite homogeneous with an estimated thickness of 2.5 μm, the ink obviously penetrates the fibres of the paper substrate. Hence, an estimation of the layer thickness is not trivial in this case.PDF Image | Inkjet-Printed Ag-Layers on Flexible, Uncoated Paper Substrates

PDF Search Title:

Inkjet-Printed Ag-Layers on Flexible, Uncoated Paper SubstratesOriginal File Name Searched:

sensors-20-02398-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |