PDF Publication Title:

Text from PDF Page: 005

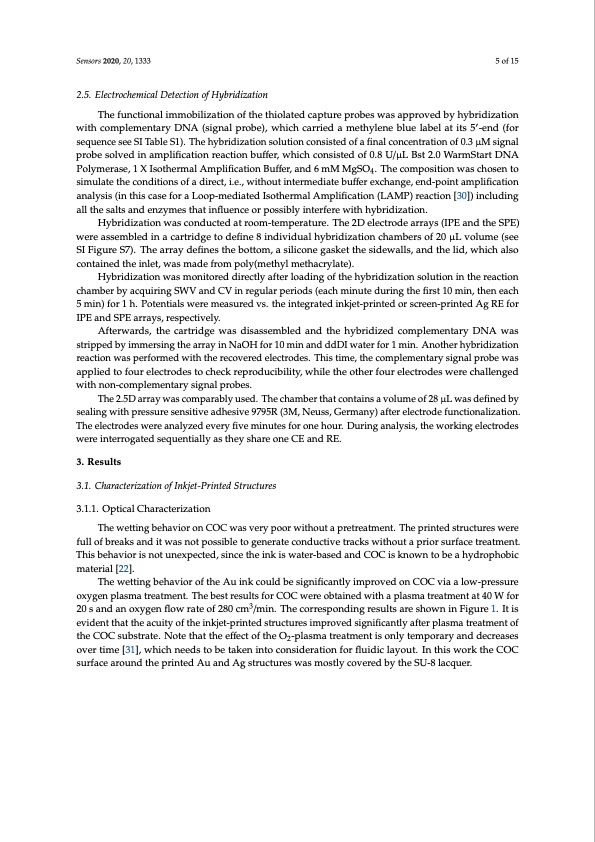

Sensors 2020, 20, 1333 5 of 15 2.5. Electrochemical Detection of Hybridization The functional immobilization of the thiolated capture probes was approved by hybridization with complementary DNA (signal probe), which carried a methylene blue label at its 5′-end (for sequence see SI Table S1). The hybridization solution consisted of a final concentration of 0.3 μM signal probe solved in amplification reaction buffer, which consisted of 0.8 U/μL Bst 2.0 WarmStart DNA Polymerase, 1 X Isothermal Amplification Buffer, and 6 mM MgSO4. The composition was chosen to simulate the conditions of a direct, i.e., without intermediate buffer exchange, end-point amplification analysis (in this case for a Loop-mediated Isothermal Amplification (LAMP) reaction [30]) including all the salts and enzymes that influence or possibly interfere with hybridization. Hybridization was conducted at room-temperature. The 2D electrode arrays (IPE and the SPE) were assembled in a cartridge to define 8 individual hybridization chambers of 20 μL volume (see SI Figure S7). The array defines the bottom, a silicone gasket the sidewalls, and the lid, which also contained the inlet, was made from poly(methyl methacrylate). Hybridization was monitored directly after loading of the hybridization solution in the reaction chamber by acquiring SWV and CV in regular periods (each minute during the first 10 min, then each 5 min) for 1 h. Potentials were measured vs. the integrated inkjet-printed or screen-printed Ag RE for IPE and SPE arrays, respectively. Afterwards, the cartridge was disassembled and the hybridized complementary DNA was stripped by immersing the array in NaOH for 10 min and ddDI water for 1 min. Another hybridization reaction was performed with the recovered electrodes. This time, the complementary signal probe was applied to four electrodes to check reproducibility, while the other four electrodes were challenged with non-complementary signal probes. The 2.5D array was comparably used. The chamber that contains a volume of 28 μL was defined by sealing with pressure sensitive adhesive 9795R (3M, Neuss, Germany) after electrode functionalization. The electrodes were analyzed every five minutes for one hour. During analysis, the working electrodes were interrogated sequentially as they share one CE and RE. 3. Results 3.1. Characterization of Inkjet-Printed Structures 3.1.1. Optical Characterization The wetting behavior on COC was very poor without a pretreatment. The printed structures were full of breaks and it was not possible to generate conductive tracks without a prior surface treatment. This behavior is not unexpected, since the ink is water-based and COC is known to be a hydrophobic material [22]. The wetting behavior of the Au ink could be significantly improved on COC via a low-pressure oxygen plasma treatment. The best results for COC were obtained with a plasma treatment at 40 W for 20 s and an oxygen flow rate of 280 cm3/min. The corresponding results are shown in Figure 1. It is evident that the acuity of the inkjet-printed structures improved significantly after plasma treatment of the COC substrate. Note that the effect of the O2-plasma treatment is only temporary and decreases over time [31], which needs to be taken into consideration for fluidic layout. In this work the COC surface around the printed Au and Ag structures was mostly covered by the SU-8 lacquer.PDF Image | Inkjet-Printing Nanoparticle Gold Silver Ink Cyclic Olefin

PDF Search Title:

Inkjet-Printing Nanoparticle Gold Silver Ink Cyclic OlefinOriginal File Name Searched:

sensors-20-01333-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |