PDF Publication Title:

Text from PDF Page: 006

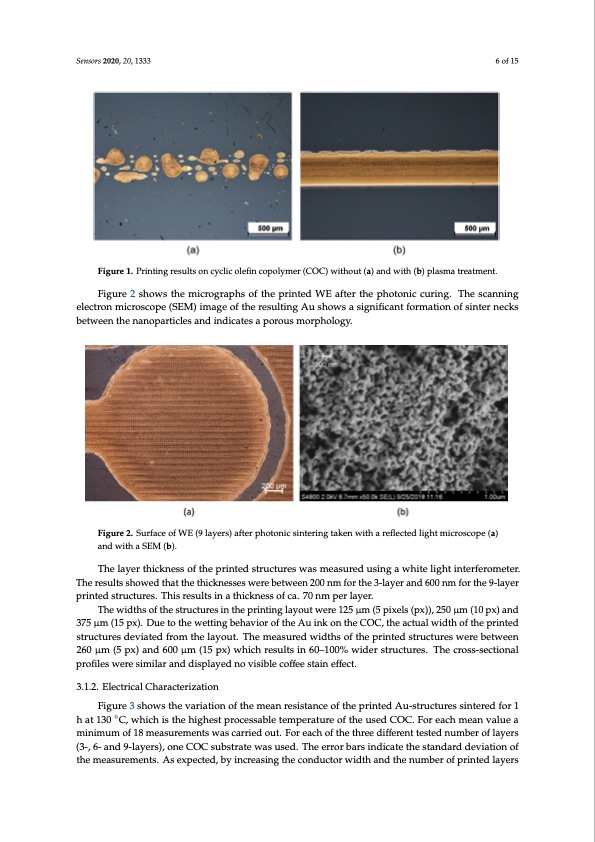

Sensors 2020, 20, 1333 Sensors 2019, 19, x FOR PEER REVIEW 6 of 15 6 of 15 6 of 15 Sensors 2019, 19, x FOR PEER REVIEW Figure 1. Printing results on cyclic olefin copolymer (COC) without (a) and with (b) plasma treatment. Figure 1. Printing results on cyclic olefin copolymer (COC) without (a) and with (b) plasma treatment. Figure 1. Printing results on cyclic olefin copolymer (COC) without (a) and with (b) plasma treatment. Figure 2 shows the micrographs of the printed WE after the photonic curing. The scanning Figure 2 shows the micrographs of the printed WE after the photonic curing. The scanning electron microscope (SEM) image of the resulting Au shows a significant formation of sinter necks electron microscope (SEM) image of the resulting Au shows a significant formation of sinter necks between the nanoparticles and indicates a porous morphology. between the nanoparticles and indicates a porous morphology. Figure 2. Surface of WE (9 layers) after photonic sintering taken with a reflected light microscope (a) Figure 2. Surface of WE (9 layers) after photonic sintering taken with a reflected light microscope (a) and with a SEM (b). and with a SEM (b). Figure 2 shows the micrographs of the printed WE after the photonic curing. The scanning The layer thickness of the printed structures was measured using a white light interferometer. electronTmheiclraoysecrotpheic(kSnEeMss) oimf tahgeporfinthtedresstruultcitnugreAsuwsahsomwesaasusrigedniufisciangt afowrmhaitteiolnigohft sininteterrfenroecmkester. The results showed that the thicknesses were between 200 nm for the 3-layer and 600 nm for the 9- betTwheernestuhletsnsahnowpaedrtitchlaetstahnedthinicdkinceastesessawpeorreobuestwmeoernph20o0longmy.for the 3-layer and 600 nm for the 9-layer layer printed structures. This results in a thickness of ca. 70 nm per layer. printed structures. This results in a thickness of ca. 70 nm per layer. The widths of the structures in the printing layout were 125 μm (5 pixels (px)), 250 μm (10 px) The widths of the structures in the printing layout were 125 μm (5 pixels (px)), 250 μm (10 px) and and 375 μm (15 px). Due to the wetting behavior of the Au ink on the COC, the actual width of the 375 μm (15 px). Due to the wetting behavior of the Au ink on the COC, the actual width of the printed Figure 2. Surface of WE (9 layers) after photonic sintering taken with a reflected light microscope (a) printed structures deviated from the layout. The measured widths of the printed structures were structures deviated from the layout. The measured widths of the printed structures were between and with a SEM (b). between 260 μm (5 px) and 600 μm (15 px) which results in 60%–100% wider structures. The cross- 260 μm (5 px) and 600 μm (15 px) which results in 60–100% wider structures. The cross-sectional sectional profiles were similar and displayed no visible coffee stain effect. profiles were similar and displayed no visible coffee stain effect. The layer thickness of the printed structures was measured using a white light interferometer. The results showed that the thicknesses were between 200 nm for the 3-layer and 600 nm for the 9- 3..1..2. EllecttrriicallCharactteriizattiion layer printed structures. This results in a thickness of ca. 70 nm per layer. Figure3sshowsstthheevvaarriaiatitoionnooffththeemmeaenanrerseisitsatnacneceofotfhteheprpinritnetdedAuA-ust-rsutrcutuctruersesinstinertedrefdorfo1rh1 The widths of the structures in the printing layout were 125 μm (5 pixels (px)), 250 μm (10 px) ◦ minimum of 18 measurements was carried out. Foreachofftthetthrreediifffferent tested number of llayers printed structures deviated from the layout. The measured widths of the printed structures were (3-, 6- and 9-layers), one COC substrate was used. The error bars indicate the standard deviation of between 260 μm (5 px) and 600 μm (15 px) which results in 60%–100% wider structures. The cross- the measurements. As expectted,, by iincreasing the conductor width and the number of printed llayers sectional profiles were similar and displayed no visible coffee stain effect. ahta1t3103°0C,Cw,hwichhicihsitshtehehihgihgehsetsptrporcoecsessasbalbeletetmempepreartautruereofofththeeuusesdedCCOOCC..FFoorreeaacchhmeaanvalluea and 375 μm (15 px). Due to the wetting behavior of the Au ink on the COC, the actual width of the 3.1.2. Electrical CharacterizationPDF Image | Inkjet-Printing Nanoparticle Gold Silver Ink Cyclic Olefin

PDF Search Title:

Inkjet-Printing Nanoparticle Gold Silver Ink Cyclic OlefinOriginal File Name Searched:

sensors-20-01333-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |