PDF Publication Title:

Text from PDF Page: 008

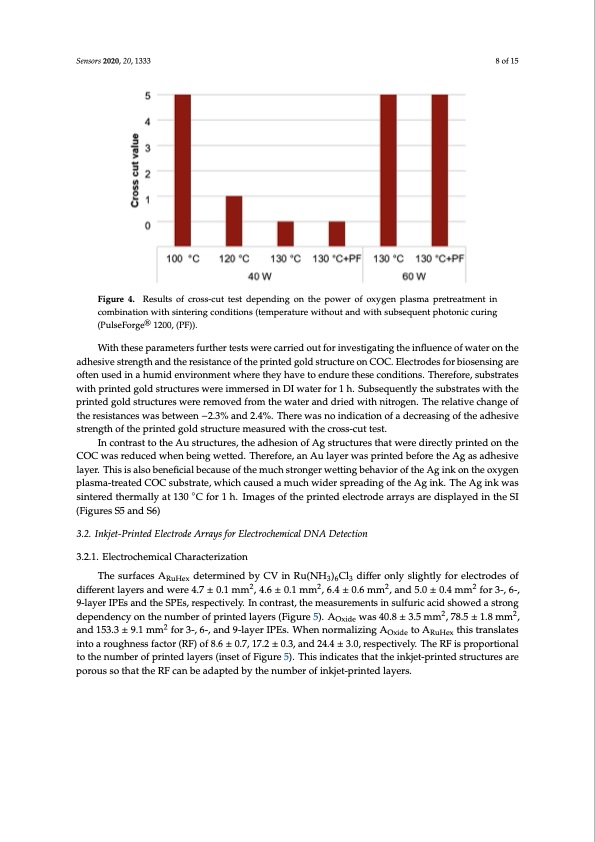

Sensors 2020, 20, 1333 8 of 15 Sensors 2019, 19, x FOR PEER REVIEW 8 of 15 Figure 4. Results of cross-cut test depending on the power of oxygen plasma pretreatment in Figure 4. Results of cross-cut test depending on the power of oxygen plasma pretreatment in combination with sintering conditions (temperature without and with subsequent photonic curing combination with sintering conditions (temperature without and with subsequent photonic curing (PulseForge® 1200, (PF)). (PulseForge® 1200, (PF)). With these parameters further tests were carried out for investigating the influence of water on the With these parameters further tests were carried out for investigating the influence of water on adhesive strength and the resistance of the printed gold structure on COC. Electrodes for biosensing are the adhesive strength and the resistance of the printed gold structure on COC. Electrodes for often used in a humid environment where they have to endure these conditions. Therefore, substrates biosensing are often used in a humid environment where they have to endure these conditions. with printed gold structures were immersed in DI water for 1 h. Subsequently the substrates with the Therefore, substrates with printed gold structures were immersed in DI water for 1 h. Subsequently printed gold structures were removed from the water and dried with nitrogen. The relative change of the substrates with the printed gold structures were removed from the water and dried with nitrogen. the resistances was between −2.3% and 2.4%. There was no indication of a decreasing of the adhesive The relative change of the resistances was between –2.3% and 2.4%. There was no indication of a strength of the printed gold structure measured with the cross-cut test. decreasing of the adhesive strength of the printed gold structure measured with the cross-cut test. In contrast to the Au structures, the adhesion of Ag structures that were directly printed on the In contrast to the Au structures, the adhesion of Ag structures that were directly printed on the COC was reduced when being wetted. Therefore, an Au layer was printed before the Ag as adhesive COC was reduced when being wetted. Therefore, an Au layer was printed before the Ag as adhesive layer. This is also beneficial because of the much stronger wetting behavior of the Ag ink on the oxygen layer. This is also beneficial because of the much stronger wetting behavior of the Ag ink on the plasma-treated COC substrate, which caused a much wider spreading of the Ag ink. The Ag ink was oxygen plasma-treated COC substrate, which caused a much wider spreading of the Ag ink. The Ag sintered thermally at 130 ◦C for 1 h. Images of the printed electrode arrays are displayed in the SI ink was sintered thermally at 130 °C for 1 h. Images of the printed electrode arrays are displayed in (Figures S5 and S6) the SI (Figure S5 and S6) 3.2. Inkjet-Printed Electrode Arrays for Electrochemical DNA Detection 3.2. Inkjet-Printed Electrode Arrays for Electrochemical DNA Detection 3.2.1. Electrochemical Characterization The surfaces ARuHex determined by CV in Ru(NH3)6Cl3 differ only slightly for electrodes of 2222 3.2.1. Electrochemical Characterization diffeTrehnet lsauyrefarsceasndARwuHeerxed4e.7te±rm0i.n1emdmby, 4C.6V±in0.1Rum(NmH,36)6.C4 l±3 d0.i6ffmermon,lyansdli5g.h0tl±y 0f.o4rmemlectrforde3s-, o6f-, 2222 d9i-flafeyrernItPlEasyearnsdatnhdeSwPeErse,4re.7sp±e0c.t1ivmelmy.I,n4c.6on±tr0a.1stm,tmhe,m6e.4as±u0re.6mmenmts,inansdul5fu.0ri±ca0c.4idmsmhowfoerd3a-,s6tr-o,n9g- 22 ldaeyperenIPdEesncayndonthteheSPnEusm, rbeesrpoecftpivrienlyte.dInlacyoenrtsra(sFti,gtuhreem5)e.aAsuremewntassi4n0s.8ul±fu3r.i5c macmid s,h7o8w.5e±d1a.8stmromng, 222 daenpde1n5d3e.n3c±y 9o.n1 tmhemnufmorb3e-r, o6f-,parnindte9d-lalayyeerrIsP(EFisg. uWreh5e)n. AnoOxrimde waliazsin40g.8A± 3.5 mtomA, 78.5 ±th1.i8s mtramns,lanteds Oxide RuHex 1in5t3o.3a±ro9u.1ghmnmessfofarc3to-,r6(R-,Fa)nodf 89.-6la±ye0r.7I,P1E7s.2. W± h0.e3n, annodrm24a.l4iz±in3g.0A, rOexsidpeetcotiAveRluyH.exTthheisRtFraisnpslraotpesoritniotonal rtoutghheneusmsfbaecrtorf(pRrFin)toefd8l.a6y±er0s.7(,in1s7e.2to±f0F.3ig,uarned52).4.T4h±is3i.0n,driecsaptesctihvaetlyth.eThinekRjeFt-ipsrpinrtoepdosrtriuonctaulrteostahre 2 npuomrobuesrsofthpartinthtedRlFaycaenrsb(einasdeatpotefdFbigyutrhee5n)u.mThbiesrionfdiinckajtets-ptrhiantetdhelaiynekrjse.t-printedstructuresare porous so that the RF can be adapted by the number of inkjet-printed layers. OxidePDF Image | Inkjet-Printing Nanoparticle Gold Silver Ink Cyclic Olefin

PDF Search Title:

Inkjet-Printing Nanoparticle Gold Silver Ink Cyclic OlefinOriginal File Name Searched:

sensors-20-01333-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |