PDF Publication Title:

Text from PDF Page: 004

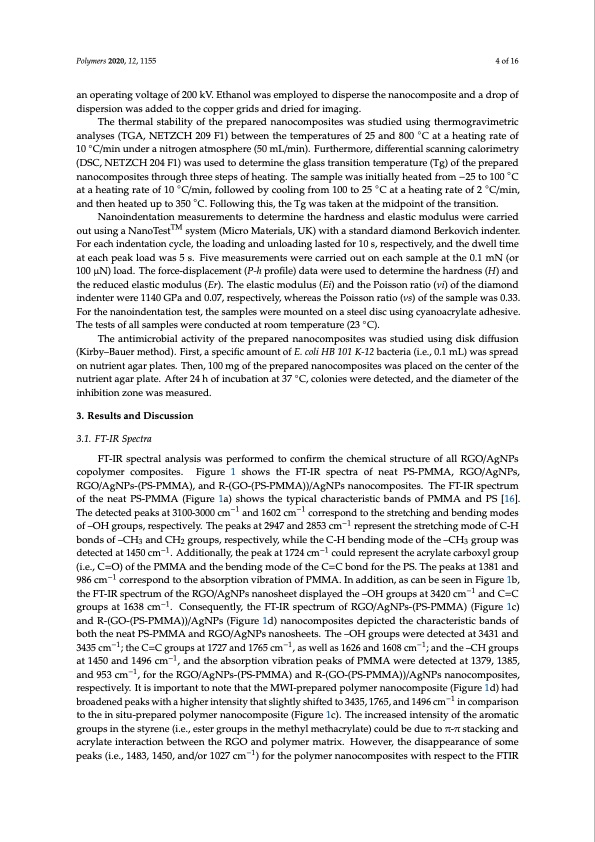

Polymers 2020, 12, 1155 4 of 16 an operating voltage of 200 kV. Ethanol was employed to disperse the nanocomposite and a drop of dispersion was added to the copper grids and dried for imaging. The thermal stability of the prepared nanocomposites was studied using thermogravimetric analyses (TGA, NETZCH 209 F1) between the temperatures of 25 and 800 ◦C at a heating rate of 10 ◦C/min under a nitrogen atmosphere (50 mL/min). Furthermore, differential scanning calorimetry (DSC, NETZCH 204 F1) was used to determine the glass transition temperature (Tg) of the prepared nanocomposites through three steps of heating. The sample was initially heated from −25 to 100 ◦C at a heating rate of 10 ◦C/min, followed by cooling from 100 to 25 ◦C at a heating rate of 2 ◦C/min, and then heated up to 350 ◦C. Following this, the Tg was taken at the midpoint of the transition. Nanoindentation measurements to determine the hardness and elastic modulus were carried out using a NanoTestTM system (Micro Materials, UK) with a standard diamond Berkovich indenter. For each indentation cycle, the loading and unloading lasted for 10 s, respectively, and the dwell time at each peak load was 5 s. Five measurements were carried out on each sample at the 0.1 mN (or 100 μN) load. The force-displacement (P-h profile) data were used to determine the hardness (H) and the reduced elastic modulus (Er). The elastic modulus (Ei) and the Poisson ratio (νi) of the diamond indenter were 1140 GPa and 0.07, respectively, whereas the Poisson ratio (νs) of the sample was 0.33. For the nanoindentation test, the samples were mounted on a steel disc using cyanoacrylate adhesive. The tests of all samples were conducted at room temperature (23 ◦C). The antimicrobial activity of the prepared nanocomposites was studied using disk diffusion (Kirby–Bauer method). First, a specific amount of E. coli HB 101 K-12 bacteria (i.e., 0.1 mL) was spread on nutrient agar plates. Then, 100 mg of the prepared nanocomposites was placed on the center of the nutrient agar plate. After 24 h of incubation at 37 ◦C, colonies were detected, and the diameter of the inhibition zone was measured. 3. Results and Discussion 3.1. FT-IR Spectra FT-IR spectral analysis was performed to confirm the chemical structure of all RGO/AgNPs copolymer composites. Figure 1 shows the FT-IR spectra of neat PS-PMMA, RGO/AgNPs, RGO/AgNPs-(PS-PMMA), and R-(GO-(PS-PMMA))/AgNPs nanocomposites. The FT-IR spectrum of the neat PS-PMMA (Figure 1a) shows the typical characteristic bands of PMMA and PS [16]. The detected peaks at 3100-3000 cm−1 and 1602 cm−1 correspond to the stretching and bending modes of –OH groups, respectively. The peaks at 2947 and 2853 cm−1 represent the stretching mode of C-H bonds of –CH3 and CH2 groups, respectively, while the C-H bending mode of the –CH3 group was detected at 1450 cm−1. Additionally, the peak at 1724 cm−1 could represent the acrylate carboxyl group (i.e., C=O) of the PMMA and the bending mode of the C=C bond for the PS. The peaks at 1381 and 986 cm−1 correspond to the absorption vibration of PMMA. In addition, as can be seen in Figure 1b, the FT-IR spectrum of the RGO/AgNPs nanosheet displayed the –OH groups at 3420 cm−1 and C=C groups at 1638 cm−1. Consequently, the FT-IR spectrum of RGO/AgNPs-(PS-PMMA) (Figure 1c) and R-(GO-(PS-PMMA))/AgNPs (Figure 1d) nanocomposites depicted the characteristic bands of both the neat PS-PMMA and RGO/AgNPs nanosheets. The –OH groups were detected at 3431 and 3435 cm−1; the C=C groups at 1727 and 1765 cm−1, as well as 1626 and 1608 cm−1; and the –CH groups at 1450 and 1496 cm−1, and the absorption vibration peaks of PMMA were detected at 1379, 1385, and 953 cm−1, for the RGO/AgNPs-(PS-PMMA) and R-(GO-(PS-PMMA))/AgNPs nanocomposites, respectively. It is important to note that the MWI-prepared polymer nanocomposite (Figure 1d) had broadened peaks with a higher intensity that slightly shifted to 3435, 1765, and 1496 cm−1 in comparison to the in situ-prepared polymer nanocomposite (Figure 1c). The increased intensity of the aromatic groups in the styrene (i.e., ester groups in the methyl methacrylate) could be due to π-π stacking and acrylate interaction between the RGO and polymer matrix. However, the disappearance of some peaks (i.e., 1483, 1450, and/or 1027 cm−1) for the polymer nanocomposites with respect to the FTIRPDF Image | Microwave Irradiation Synthesis Silver Nanoparticle

PDF Search Title:

Microwave Irradiation Synthesis Silver NanoparticleOriginal File Name Searched:

polymers-12-01155-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |