PDF Publication Title:

Text from PDF Page: 009

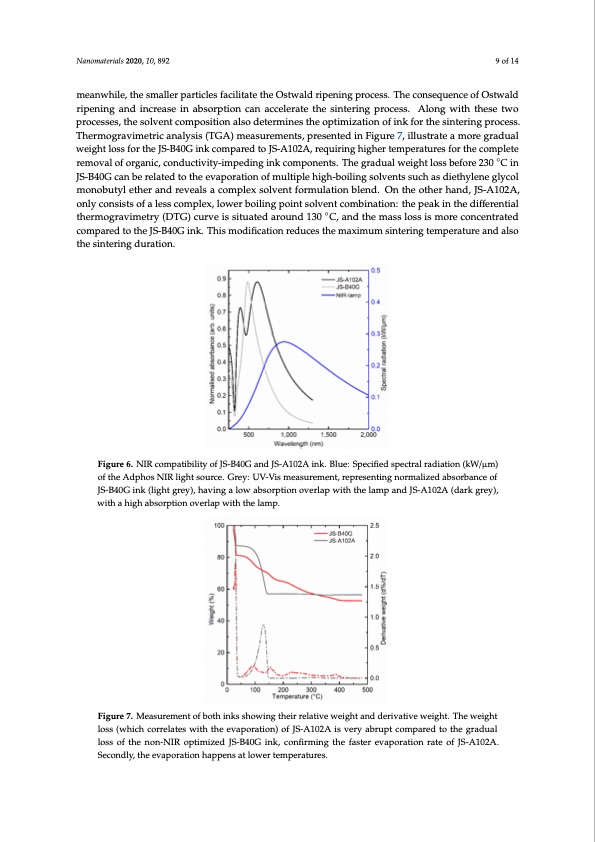

progresses, the surface free energy of all particles will gradually reduce, resulting in less Ostwald ripening. Meanwhile, particle migration (coalescence) becomes the main sintering mechanism. The bigger particles will coalesce and aggregate together randomly, forming necks and eventually completely merge together. Besides these main mechanisms, there are still some particle and ink formulation related properties which could influence the sintering progress. One of these is the effect Nanomaterials 2020, 10, 892 9 of 14 of a polymer capping agent used to stop nanoparticles from agglomerating before sintering. As the thickness of the capping layer is less than a few nm and decompose in the primary stage of the sintering procedure, its effect on sintering is negligible [26,36]. However, the thermal stability of the meanwhile, the smaller particles facilitate the Ostwald ripening process. The consequence of Ostwald capping plays a significant role on the sintering temperature required to form a conductive path. ripening and increase in absorption can accelerate the sintering process. Along with these two NAanomthateriaclso2n0d20i,t1io0,nx wFOhRicPhEEaRffReEcVtsIEtWhe sintering is the type of solvent used in the ink. A low bo9iolifn1g4 processes, the solvent composition also determines the optimization of ink for the sintering process. point solvent evaporates much faster than a high boiling point solvent, resulting in the particles Thermogravimetric analysis (TGA) measurements, presented in Figure 7, illustrate a more gradual comiTnhgecUloVse-rVtIoS emacehasoutrheemr efansttesrhoanwds theartetfhoereJSh-eBl4p0tGheintwk ohaesaritlsiemr daxesimcruibmedambseocrhbanicsempse(aOksatwt 4a8l6d weight loss for the JS-B40G ink compared to JS-A102A, requiring higher temperatures for the complete nm. Dynamic light scattering measurement of the ink batch undertaken by the supplier shows that ripening and coalescence). This has a significant influence on the sintering time. Finally, the last removal of organic, conductivity-impeding ink components. The gradual weight loss before 230 ◦C in tdhescJSri-bBe4d0Gconindkithioans iasnthaevperaargtieclpeasritziec.leSisnicze tohfe6s9iznemof. tWhehsennacanlocpualartinclgesthiseinmtahxeimlouwmerenxmtinrcatniogne JSb-Ba4se0dGocnanthbeeMrielathtedortyo,t6h9enemvadpiaomraettieornpoafrtmiculelstihpalveehtihgehi-rbmoialxinimgusomlvaebnstosrbsuanchceaastd48ie2thnymle, wnehgiclhycol (between 20 and 100 nm), they are subjected to scattering when being photonically sintered. Upon miosninobaucctyorldeatnhceerwanitdhroeuvreeaxlpsearicmoemnpt[l4e1x–s4o5l]v.entformulationblend.Ontheotherhand,JS-A102A, photo incidence, the localized surface plasmon resonance (LSPR) of the silver nanoparticles prevails onilfytchoeInicsnriecsiatdseionfgtatlhilgehspstacrroetsmicolnpealsenixztl,eylosmhwiafetrschbtheoesilmiwnaigtxhpimothiunemtlsoaocblasvloiezrnebtdacnofcimelpdbeinaokafttAiogwnN:aPrtdhsseaapnedhaigkhheienrctewh,eaavdletielffersnergtethnhetial ◦ thaeanrbmdsoomrbgartancvhceimnbgyetbsrecytat(tetDrerTwinGitg)htchtuherevrwaedaiisvaetsilioetnun.gaLtheSdPoRfaropoururimnNdaIrR1il3yl0igdheCtp,esanonuddrscoethn. Hethmoewasesizvselro,sfasthbiseigmAgegorNrepac,rodtniicecllencstirziaected wcoilnlstaalsnot roefdsuoclevethnetsmuasxeidmaunmdatbhseorwbanvceelenogfttheofinikncainddenrtedraudcieattihoen.efFfiegcutroef6Osthwoawlds brioptehniingk compared to the JS-B40G ink. This modification reduces the maximum sintering temperature and also because these particles are more stable. This results in a trade-off system between the sintering theabssionrtberaincge danudrathioenla. mp spectral radiation as a function of the wavelength. mechanism speed and the amount of light, and thus heat absorbance. Based on these parameters, a second commercially available ink was studied, namely, JS-A102A. This ink is stated to be optimized for photonic sintering. JS-A102A has an average particle size of 36 nm, based on a dynamic light scattering measurement (DLS) of the ink batch performed by the supplier. However, the size distribution in this ink is different from JS-B40G ink. DLS data show two Gaussian curves, instead of one for JS-B40G, with maxima at a particle diameter of ± 12 nm and ± 76 nm. The particle size distribution consists of both small and bigger particles, the maximum absorbance wavelength of bigger sized particles matches with the NIR radiation, increasing the absorption and meanwhile, the smaller particles facilitate the Ostwald ripening process. The consequence of Ostwald ripening and increase in absorption can accelerate the sintering process. Along with these two processes, the solvent composition also determines the optimization of ink for the sintering process. Thermogravimetric analysis (TGA) measurements, presented in Figure 7, illustrate a more gradual weight loss for the JS-B40G ink compared to JS-A102A, requiring higher temperatures for the complete removal of organic, conductivity-impeding ink components. The gradual weight loss before 230 °C in JS-B40G can be related to the evaporation of multiple high- boiling solvents such as diethylene glycol monobutyl ether and reveals a complex solvent formulation blend. On the other hand, JS-A102A, only consists of a less complex, lower boiling point Figure 6. NIR compatibility of JS-B40G and JS-A102A ink. Blue: Specified spectral radiation (kW/μm) Figure 6. NIR compatibility of JS-B40G and JS-A102A ink. Blue: Specified spectral radiation (kW/μm) solveonfttchoemAbdipnhaotsioNnI:Rthlieghptesaokuricne.tGheredy:ifUfeVr-eVnitsiamletahseurrmemoegnrat,vriempretsreynt(iDngTnGo)rmcuarlvizedisasbistourabtaendceaorof und of the Adphos NIR light source. Grey: UV-Vis measurement, representing normalized absorbance of 130 °JCS,-Ba4n0dG itnhke (mligahstsglroeyss), hisavminogrea lcoowncaebnsotrapteiodn coovmerplaaprewdithtothtehelamJSp-Ba4n0dGJSi-nAk1.02TAhi(sdamrkogdriefyic)a, tion JS-B40G ink (light grey), having a low absorption overlap with the lamp and JS-A102A (dark grey), reducwesiththaehmigahxaibmsourmptisointoevreinrlgaptewmitphetrhaetularmepa.nd also the sintering duration. with a high absorption overlap with the lamp. FiFgiugruere7.7M. Meeaassuurreemeenttoffboth inks showiingttheeirirrreelalatitviveewweiegihgthatnadndedreivriavtiavteivweewigehigt.hTth. eTwheiwghetight lolsosss(w(whhicichhccorrelates wiitthththeeeveavpaoproartiaotnio)no)f JoSf-AJS1-0A21A02isAveisryvaebrryupabt cruomptpcaoremdptoartehde gtoratdhuealglroasdsual loossf tohfe nthoen-nNoInR-NopItRimoizpetdimJSiz-Be4d0GJS-inBk4,0cGonifnirkm, icnogntfihremfaisntgertehveapfaosratetironevratpeoorfaJtSio-An1r0a2tAe.oSfecJoSn-Adl1y0,2A. the evaporation happens at lower temperatures. Secondly, the evaporation happens at lower temperatures. 3.4. NIR Flash Sintering of JS-A102A InkPDF Image | Nanoparticle Inkjet Inks for Near-Infrared Sintering

PDF Search Title:

Nanoparticle Inkjet Inks for Near-Infrared SinteringOriginal File Name Searched:

nanomaterials-10-00892.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |