PDF Publication Title:

Text from PDF Page: 005

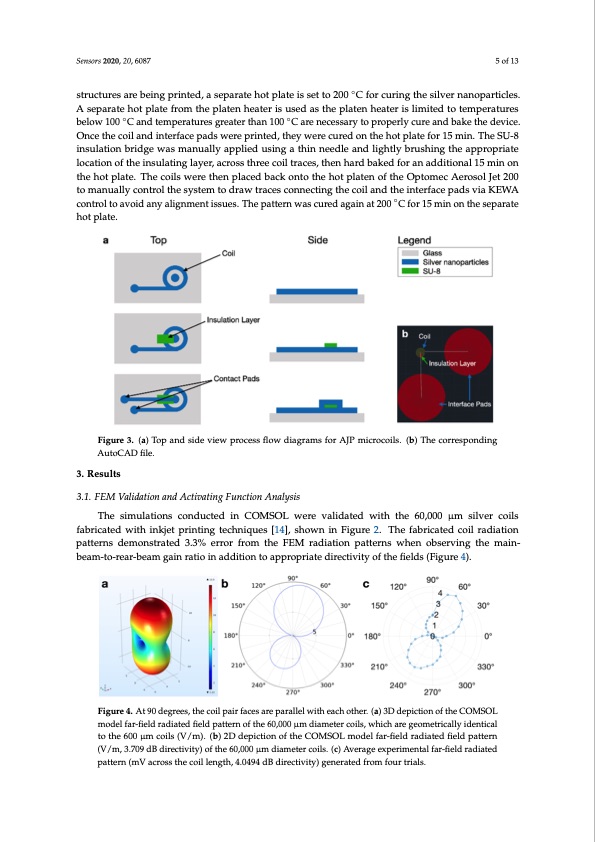

Sensors 2020, 20, 6087 5 of 13 structures are being printed, a separate hot plate is set to 200 ◦C for curing the silver nanoparticles. A separate hot plate from the platen heater is used as the platen heater is limited to temperatures below 100 ◦C and temperatures greater than 100 ◦C are necessary to properly cure and bake the device. Once the coil and interface pads were printed, they were cured on the hot plate for 15 min. The SU-8 insulation bridge was manually applied using a thin needle and lightly brushing the appropriate location of the insulating layer, across three coil traces, then hard baked for an additional 15 min on the hot plate. The coils were then placed back onto the hot platen of the Optomec Aerosol Jet 200 to manually control the system to draw traces connecting the coil and the interface pads via KEWA control to avoid any alignment issues. The pattern was cured again at 200 ◦C for 15 min on the separate hot plate. Figure 3. (a) Top and side view process flow diagrams for AJP microcoils. (b) The corresponding AutoCAD file. 3. Results 3.1. FEM Validation and Activating Function Analysis The simulations conducted in COMSOL were validated with the 60,000 μm silver coils fabricated with inkjet printing techniques [14], shown in Figure 2. The fabricated coil radiation patterns demonstrated 3.3% error from the FEM radiation patterns when observing the main- beam-to-rear-beam gain ratio in addition to appropriate directivity of the fields (Figure 4). Figure 4. At 90 degrees, the coil pair faces are parallel with each other. (a) 3D depiction of the COMSOL model far-field radiated field pattern of the 60,000 μm diameter coils, which are geometrically identical to the 600 μm coils (V/m). (b) 2D depiction of the COMSOL model far-field radiated field pattern (V/m, 3.709 dB directivity) of the 60,000 μm diameter coils. (c) Average experimental far-field radiated pattern (mV across the coil length, 4.0494 dB directivity) generated from four trials.PDF Image | Silver-Nanoparticle Microcoil via Aerosol Jet Printing

PDF Search Title:

Silver-Nanoparticle Microcoil via Aerosol Jet PrintingOriginal File Name Searched:

sensors-20-06087-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |