PDF Publication Title:

Text from PDF Page: 007

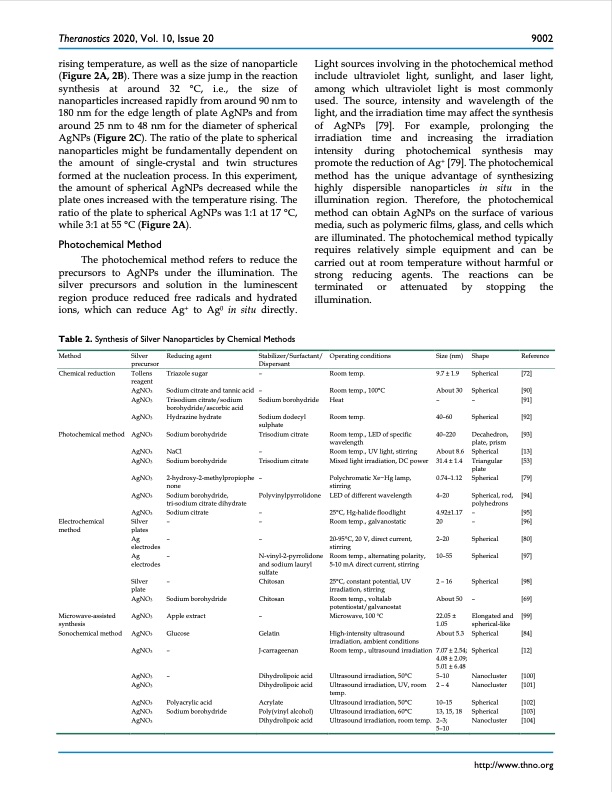

Theranostics 2020, Vol. 10, Issue 20 rising temperature, as well as the size of nanoparticle (Figure 2A, 2B). There was a size jump in the reaction synthesis at around 32 °C, i.e., the size of nanoparticles increased rapidly from around 90 nm to 180 nm for the edge length of plate AgNPs and from around 25 nm to 48 nm for the diameter of spherical AgNPs(Figure2C).Theratiooftheplatetospherical nanoparticles might be fundamentally dependent on the amount of single-crystal and twin structures formed at the nucleation process. In this experiment, the amount of spherical AgNPs decreased while the plate ones increased with the temperature rising. The ratio of the plate to spherical AgNPs was 1:1 at 17 °C, while 3:1 at 55 °C (Figure 2A). Photochemical Method The photochemical method refers to reduce the precursors to AgNPs under the illumination. The silver precursors and solution in the luminescent region produce reduced free radicals and hydrated ions, which can reduce Ag+ to Ag0 in situ directly. Table 2. Synthesis of Silver Nanoparticles by Chemical Methods 9002 Light sources involving in the photochemical method include ultraviolet light, sunlight, and laser light, among which ultraviolet light is most commonly used. The source, intensity and wavelength of the light, and the irradiation time may affect the synthesis of AgNPs [79]. For example, prolonging the irradiation time and increasing the irradiation intensity during photochemical synthesis may promote the reduction of Ag+ [79]. The photochemical method has the unique advantage of synthesizing highly dispersible nanoparticles in situ in the illumination region. Therefore, the photochemical method can obtain AgNPs on the surface of various media, such as polymeric films, glass, and cells which are illuminated. The photochemical method typically requires relatively simple equipment and can be carried out at room temperature without harmful or strong reducing agents. The reactions can be terminated illumination. or attenuated by stopping the Method Chemical reduction Photochemical method Electrochemical method Microwave-assisted synthesis Sonochemical method Silver precursor Tollens reagent AgNO3 AgNO3 AgNO3 AgNO3 AgNO3 AgNO3 AgNO3 AgNO3 AgNO3 Silver plates Ag electrodes Ag electrodes Silver plate AgNO3 AgNO3 AgNO3 AgNO3 AgNO3 AgNO3 AgNO3 AgNO3 AgNO3 Reducing agent Triazole sugar Sodium citrate and tannic acid Trisodium citrate/sodium borohydride/ascorbic acid Hydrazine hydrate Sodium borohydride NaCl Sodium borohydride 2-hydroxy-2-methylpropiophe none Sodium borohydride, tri-sodium citrate dihydrate Sodium citrate – – – – Sodium borohydride Apple extract Glucose – – Polyacrylic acid Sodium borohydride Stabilizer/Surfactant/ Dispersant – – Sodium borohydride Sodium dodecyl sulphate Trisodium citrate – Trisodium citrate – Polyvinylpyrrolidone – – – N-vinyl-2-pyrrolidone and sodium lauryl sulfate Chitosan Chitosan – Gelatin J-carrageenan Dihydrolipoic acid Dihydrolipoic acid Acrylate Poly(vinyl alcohol) Dihydrolipoic acid Operating conditions Room temp. Room temp., 100°C Heat Room temp. Room temp., LED of specific wavelength Room temp., UV light, stirring Mixed light irradiation, DC power Polychromatic Xe−Hg lamp, stirring LED of different wavelength 25°C, Hg-halide floodlight Room temp., galvanostatic 20-95°C, 20 V, direct current, stirring Room temp., alternating polarity, 5-10 mA direct current, stirring 25°C, constant potential, UV irradiation, stirring Room temp., voltalab potentiostat/galvanostat Microwave, 100 °C High-intensity ultrasound irradiation, ambient conditions Room temp., ultrasound irradiation Ultrasound irradiation, 50°C Ultrasound irradiation, UV, room temp. Ultrasound irradiation, 50°C Ultrasound irradiation, 60°C Ultrasound irradiation, room temp. Size (nm) 9.7 ± 1.9 About 30 – 40–60 40–220 About 8.6 31.4 ± 1.4 0.74–1.12 4–20 4.92±1.17 20 2–20 10–55 2–16 About 50 22.05 ± 1.05 About 5.3 7.07 ± 2.54; 4.08 ± 2.09; 5.01 ± 6.48 5–10 2–4 10–15 13, 15, 18 2–3; 5–10 Shape Reference Spherical [72] Spherical [90] – [91] Spherical [92] Decahedron, [93] plate, prism Spherical [13] Triangular [53] plate Spherical [79] Spherical, rod, [94] polyhedrons – [95] – [96] Spherical [80] Spherical [97] Spherical [98] – [69] Elongated and [99] spherical-like Spherical [84] Spherical [12] Nanocluster [100] Nanocluster [101] Spherical [102] Spherical [103] Nanocluster [104] http://www.thno.orgPDF Image | Silver nanoparticles Synthesis medical applications safety

PDF Search Title:

Silver nanoparticles Synthesis medical applications safetyOriginal File Name Searched:

thnov10p8996.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |