PDF Publication Title:

Text from PDF Page: 033

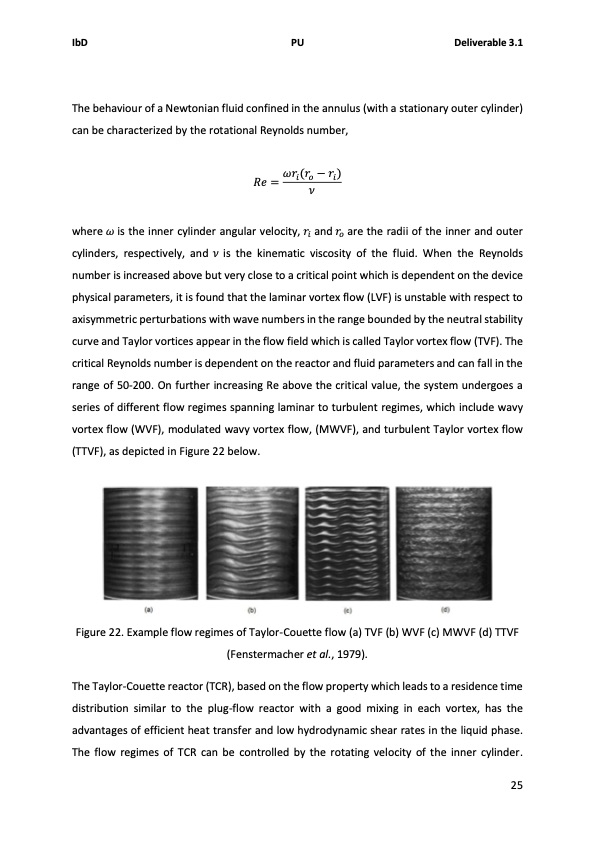

IbD PU Deliverable 3.1 The behaviour of a Newtonian fluid confined in the annulus (with a stationary outer cylinder) can be characterized by the rotational Reynolds number, 𝑅𝑒 = 𝜔𝑟𝑖(𝑟𝑜 − 𝑟𝑖) 𝜈 where 𝜔 is the inner cylinder angular velocity, 𝑟𝑖 and 𝑟𝑜 are the radii of the inner and outer cylinders, respectively, and 𝜈 is the kinematic viscosity of the fluid. When the Reynolds number is increased above but very close to a critical point which is dependent on the device physical parameters, it is found that the laminar vortex flow (LVF) is unstable with respect to axisymmetric perturbations with wave numbers in the range bounded by the neutral stability curve and Taylor vortices appear in the flow field which is called Taylor vortex flow (TVF). The critical Reynolds number is dependent on the reactor and fluid parameters and can fall in the range of 50-200. On further increasing Re above the critical value, the system undergoes a series of different flow regimes spanning laminar to turbulent regimes, which include wavy vortex flow (WVF), modulated wavy vortex flow, (MWVF), and turbulent Taylor vortex flow (TTVF), as depicted in Figure 22 below. Figure 22. Example flow regimes of Taylor-Couette flow (a) TVF (b) WVF (c) MWVF (d) TTVF (Fenstermacher et al., 1979). The Taylor-Couette reactor (TCR), based on the flow property which leads to a residence time distribution similar to the plug-flow reactor with a good mixing in each vortex, has the advantages of efficient heat transfer and low hydrodynamic shear rates in the liquid phase. The flow regimes of TCR can be controlled by the rotating velocity of the inner cylinder. 25PDF Image | Solids handling for intensified process technology

PDF Search Title:

Solids handling for intensified process technologyOriginal File Name Searched:

solids-handling-sdr.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |