PDF Publication Title:

Text from PDF Page: 040

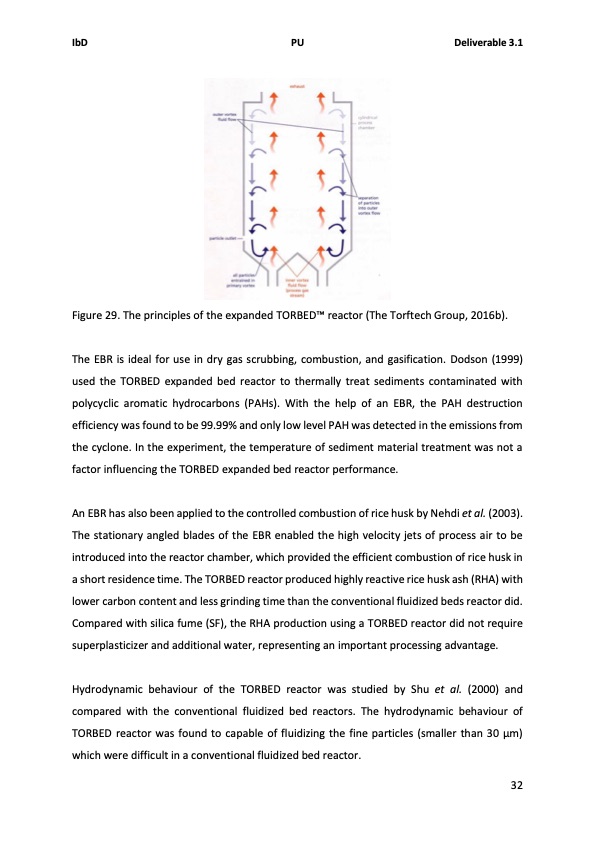

IbD PU Deliverable 3.1 Figure 29. The principles of the expanded TORBEDTM reactor (The Torftech Group, 2016b). The EBR is ideal for use in dry gas scrubbing, combustion, and gasification. Dodson (1999) used the TORBED expanded bed reactor to thermally treat sediments contaminated with polycyclic aromatic hydrocarbons (PAHs). With the help of an EBR, the PAH destruction efficiency was found to be 99.99% and only low level PAH was detected in the emissions from the cyclone. In the experiment, the temperature of sediment material treatment was not a factor influencing the TORBED expanded bed reactor performance. An EBR has also been applied to the controlled combustion of rice husk by Nehdi et al. (2003). The stationary angled blades of the EBR enabled the high velocity jets of process air to be introduced into the reactor chamber, which provided the efficient combustion of rice husk in a short residence time. The TORBED reactor produced highly reactive rice husk ash (RHA) with lower carbon content and less grinding time than the conventional fluidized beds reactor did. Compared with silica fume (SF), the RHA production using a TORBED reactor did not require superplasticizer and additional water, representing an important processing advantage. Hydrodynamic behaviour of the TORBED reactor was studied by Shu et al. (2000) and compared with the conventional fluidized bed reactors. The hydrodynamic behaviour of TORBED reactor was found to capable of fluidizing the fine particles (smaller than 30 μm) which were difficult in a conventional fluidized bed reactor. 32PDF Image | Solids handling for intensified process technology

PDF Search Title:

Solids handling for intensified process technologyOriginal File Name Searched:

solids-handling-sdr.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |