PDF Publication Title:

Text from PDF Page: 051

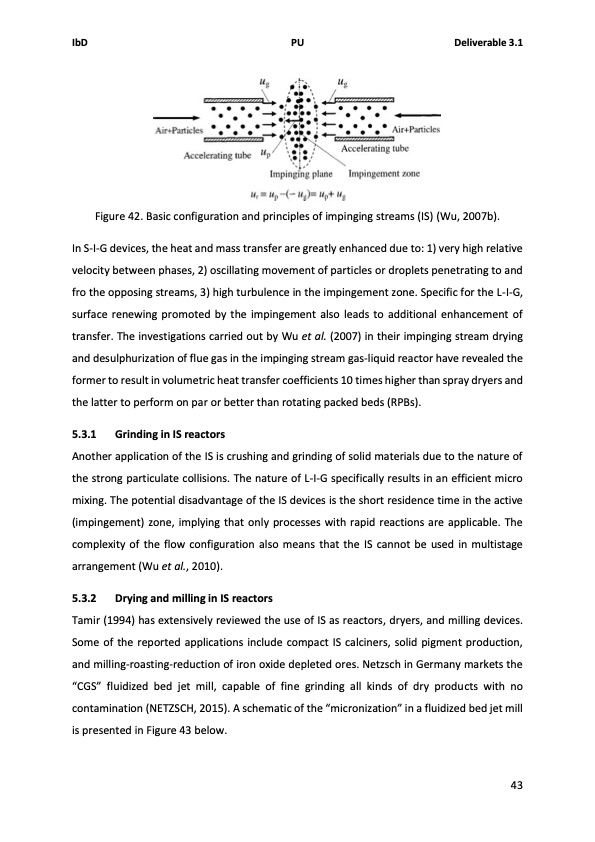

IbD PU Deliverable 3.1 Figure 42. Basic configuration and principles of impinging streams (IS) (Wu, 2007b). In S-I-G devices, the heat and mass transfer are greatly enhanced due to: 1) very high relative velocity between phases, 2) oscillating movement of particles or droplets penetrating to and fro the opposing streams, 3) high turbulence in the impingement zone. Specific for the L-I-G, surface renewing promoted by the impingement also leads to additional enhancement of transfer. The investigations carried out by Wu et al. (2007) in their impinging stream drying and desulphurization of flue gas in the impinging stream gas-liquid reactor have revealed the former to result in volumetric heat transfer coefficients 10 times higher than spray dryers and the latter to perform on par or better than rotating packed beds (RPBs). 5.3.1 Grinding in IS reactors Another application of the IS is crushing and grinding of solid materials due to the nature of the strong particulate collisions. The nature of L-I-G specifically results in an efficient micro mixing. The potential disadvantage of the IS devices is the short residence time in the active (impingement) zone, implying that only processes with rapid reactions are applicable. The complexity of the flow configuration also means that the IS cannot be used in multistage arrangement (Wu et al., 2010). 5.3.2 Drying and milling in IS reactors Tamir (1994) has extensively reviewed the use of IS as reactors, dryers, and milling devices. Some of the reported applications include compact IS calciners, solid pigment production, and milling-roasting-reduction of iron oxide depleted ores. Netzsch in Germany markets the “CGS” fluidized bed jet mill, capable of fine grinding all kinds of dry products with no contamination (NETZSCH, 2015). A schematic of the “micronization” in a fluidized bed jet mill is presented in Figure 43 below. 43PDF Image | Solids handling for intensified process technology

PDF Search Title:

Solids handling for intensified process technologyOriginal File Name Searched:

solids-handling-sdr.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |