PDF Publication Title:

Text from PDF Page: 054

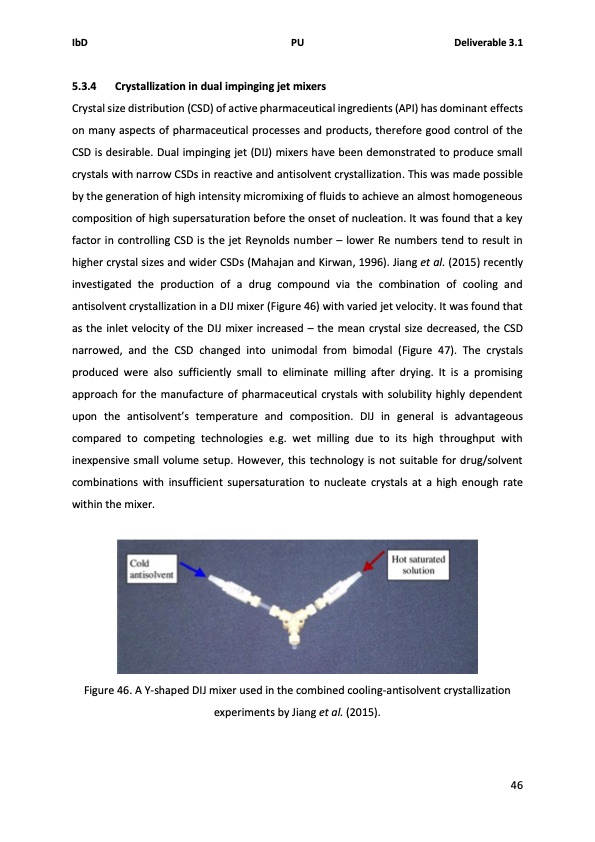

IbD PU Deliverable 3.1 5.3.4 Crystallization in dual impinging jet mixers Crystal size distribution (CSD) of active pharmaceutical ingredients (API) has dominant effects on many aspects of pharmaceutical processes and products, therefore good control of the CSD is desirable. Dual impinging jet (DIJ) mixers have been demonstrated to produce small crystals with narrow CSDs in reactive and antisolvent crystallization. This was made possible by the generation of high intensity micromixing of fluids to achieve an almost homogeneous composition of high supersaturation before the onset of nucleation. It was found that a key factor in controlling CSD is the jet Reynolds number – lower Re numbers tend to result in higher crystal sizes and wider CSDs (Mahajan and Kirwan, 1996). Jiang et al. (2015) recently investigated the production of a drug compound via the combination of cooling and antisolvent crystallization in a DIJ mixer (Figure 46) with varied jet velocity. It was found that as the inlet velocity of the DIJ mixer increased – the mean crystal size decreased, the CSD narrowed, and the CSD changed into unimodal from bimodal (Figure 47). The crystals produced were also sufficiently small to eliminate milling after drying. It is a promising approach for the manufacture of pharmaceutical crystals with solubility highly dependent upon the antisolvent’s temperature and composition. DIJ in general is advantageous compared to competing technologies e.g. wet milling due to its high throughput with inexpensive small volume setup. However, this technology is not suitable for drug/solvent combinations with insufficient supersaturation to nucleate crystals at a high enough rate within the mixer. Figure 46. A Y-shaped DIJ mixer used in the combined cooling-antisolvent crystallization experiments by Jiang et al. (2015). 46PDF Image | Solids handling for intensified process technology

PDF Search Title:

Solids handling for intensified process technologyOriginal File Name Searched:

solids-handling-sdr.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |