PDF Publication Title:

Text from PDF Page: 059

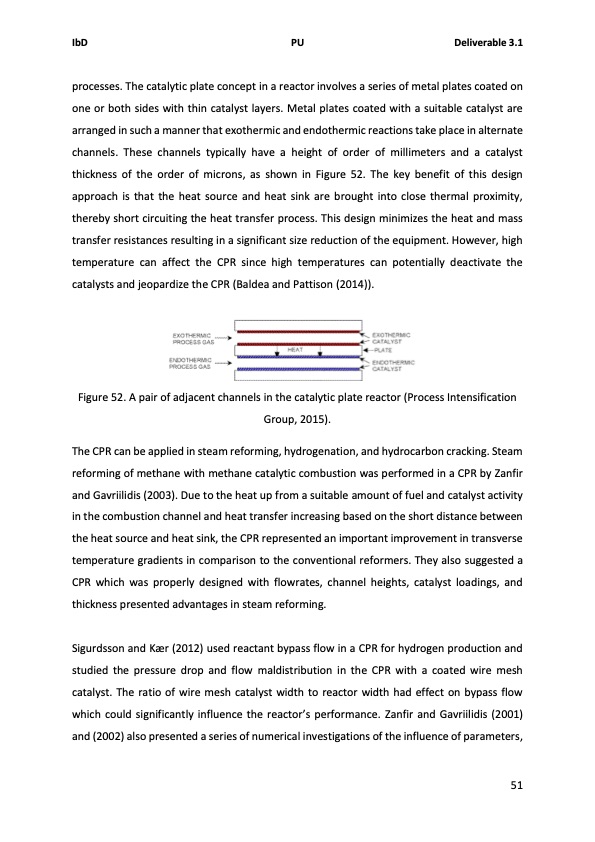

IbD PU Deliverable 3.1 processes. The catalytic plate concept in a reactor involves a series of metal plates coated on one or both sides with thin catalyst layers. Metal plates coated with a suitable catalyst are arranged in such a manner that exothermic and endothermic reactions take place in alternate channels. These channels typically have a height of order of millimeters and a catalyst thickness of the order of microns, as shown in Figure 52. The key benefit of this design approach is that the heat source and heat sink are brought into close thermal proximity, thereby short circuiting the heat transfer process. This design minimizes the heat and mass transfer resistances resulting in a significant size reduction of the equipment. However, high temperature can affect the CPR since high temperatures can potentially deactivate the catalysts and jeopardize the CPR (Baldea and Pattison (2014)). Figure 52. A pair of adjacent channels in the catalytic plate reactor (Process Intensification Group, 2015). The CPR can be applied in steam reforming, hydrogenation, and hydrocarbon cracking. Steam reforming of methane with methane catalytic combustion was performed in a CPR by Zanfir and Gavriilidis (2003). Due to the heat up from a suitable amount of fuel and catalyst activity in the combustion channel and heat transfer increasing based on the short distance between the heat source and heat sink, the CPR represented an important improvement in transverse temperature gradients in comparison to the conventional reformers. They also suggested a CPR which was properly designed with flowrates, channel heights, catalyst loadings, and thickness presented advantages in steam reforming. Sigurdsson and Kær (2012) used reactant bypass flow in a CPR for hydrogen production and studied the pressure drop and flow maldistribution in the CPR with a coated wire mesh catalyst. The ratio of wire mesh catalyst width to reactor width had effect on bypass flow which could significantly influence the reactor’s performance. Zanfir and Gavriilidis (2001) and (2002) also presented a series of numerical investigations of the influence of parameters, 51PDF Image | Solids handling for intensified process technology

PDF Search Title:

Solids handling for intensified process technologyOriginal File Name Searched:

solids-handling-sdr.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |