PDF Publication Title:

Text from PDF Page: 067

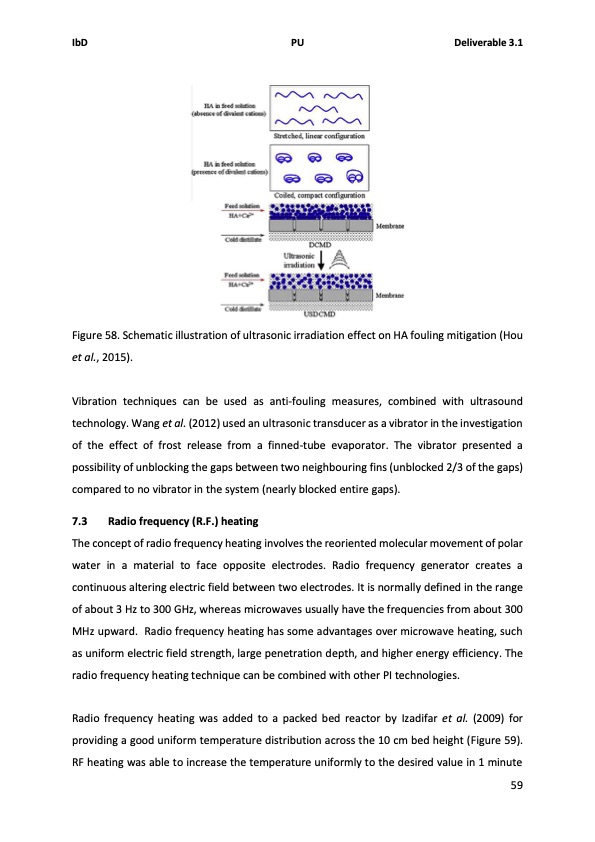

IbD PU Deliverable 3.1 Figure 58. Schematic illustration of ultrasonic irradiation effect on HA fouling mitigation (Hou et al., 2015). Vibration techniques can be used as anti-fouling measures, combined with ultrasound technology. Wang et al. (2012) used an ultrasonic transducer as a vibrator in the investigation of the effect of frost release from a finned-tube evaporator. The vibrator presented a possibility of unblocking the gaps between two neighbouring fins (unblocked 2/3 of the gaps) compared to no vibrator in the system (nearly blocked entire gaps). 7.3 Radio frequency (R.F.) heating The concept of radio frequency heating involves the reoriented molecular movement of polar water in a material to face opposite electrodes. Radio frequency generator creates a continuous altering electric field between two electrodes. It is normally defined in the range of about 3 Hz to 300 GHz, whereas microwaves usually have the frequencies from about 300 MHz upward. Radio frequency heating has some advantages over microwave heating, such as uniform electric field strength, large penetration depth, and higher energy efficiency. The radio frequency heating technique can be combined with other PI technologies. Radio frequency heating was added to a packed bed reactor by Izadifar et al. (2009) for providing a good uniform temperature distribution across the 10 cm bed height (Figure 59). RF heating was able to increase the temperature uniformly to the desired value in 1 minute 59PDF Image | Solids handling for intensified process technology

PDF Search Title:

Solids handling for intensified process technologyOriginal File Name Searched:

solids-handling-sdr.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |