PDF Publication Title:

Text from PDF Page: 088

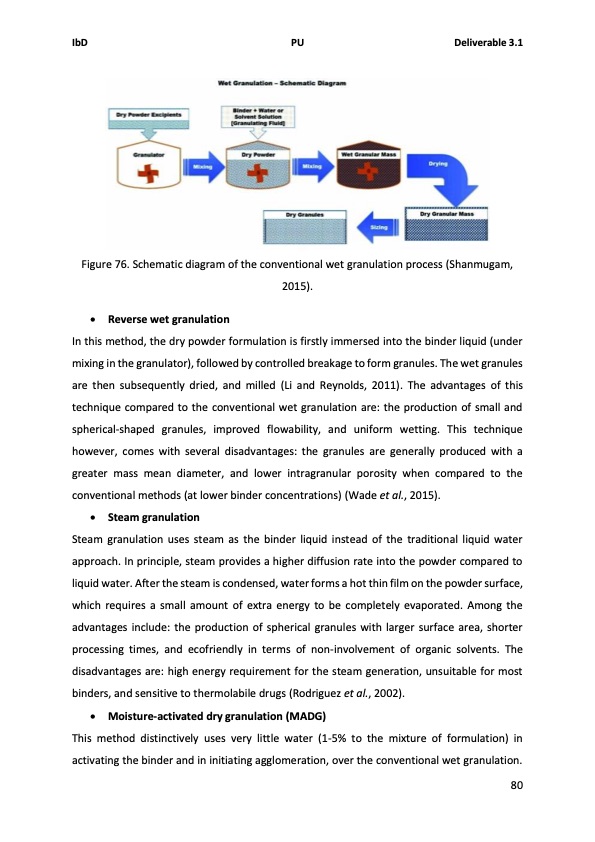

IbD PU Deliverable 3.1 Figure 76. Schematic diagram of the conventional wet granulation process (Shanmugam, 2015). Reverse wet granulation In this method, the dry powder formulation is firstly immersed into the binder liquid (under mixing in the granulator), followed by controlled breakage to form granules. The wet granules are then subsequently dried, and milled (Li and Reynolds, 2011). The advantages of this technique compared to the conventional wet granulation are: the production of small and spherical-shaped granules, improved flowability, and uniform wetting. This technique however, comes with several disadvantages: the granules are generally produced with a greater mass mean diameter, and lower intragranular porosity when compared to the conventional methods (at lower binder concentrations) (Wade et al., 2015). Steam granulation Steam granulation uses steam as the binder liquid instead of the traditional liquid water approach. In principle, steam provides a higher diffusion rate into the powder compared to liquid water. After the steam is condensed, water forms a hot thin film on the powder surface, which requires a small amount of extra energy to be completely evaporated. Among the advantages include: the production of spherical granules with larger surface area, shorter processing times, and ecofriendly in terms of non-involvement of organic solvents. The disadvantages are: high energy requirement for the steam generation, unsuitable for most binders, and sensitive to thermolabile drugs (Rodriguez et al., 2002). Moisture-activated dry granulation (MADG) This method distinctively uses very little water (1-5% to the mixture of formulation) in activating the binder and in initiating agglomeration, over the conventional wet granulation. 80PDF Image | Solids handling for intensified process technology

PDF Search Title:

Solids handling for intensified process technologyOriginal File Name Searched:

solids-handling-sdr.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |