PDF Publication Title:

Text from PDF Page: 094

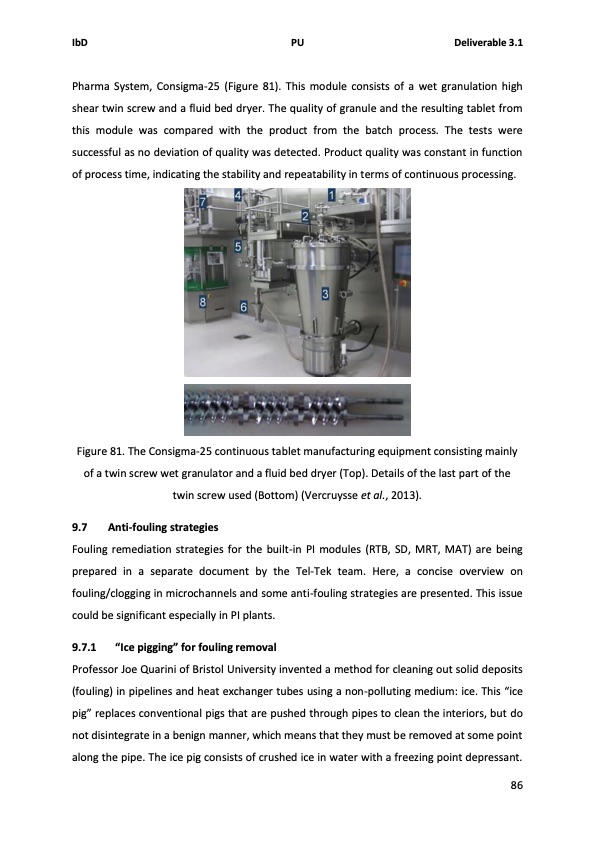

IbD PU Deliverable 3.1 Pharma System, Consigma-25 (Figure 81). This module consists of a wet granulation high shear twin screw and a fluid bed dryer. The quality of granule and the resulting tablet from this module was compared with the product from the batch process. The tests were successful as no deviation of quality was detected. Product quality was constant in function of process time, indicating the stability and repeatability in terms of continuous processing. Figure 81. The Consigma-25 continuous tablet manufacturing equipment consisting mainly of a twin screw wet granulator and a fluid bed dryer (Top). Details of the last part of the twin screw used (Bottom) (Vercruysse et al., 2013). 9.7 Anti-fouling strategies Fouling remediation strategies for the built-in PI modules (RTB, SD, MRT, MAT) are being prepared in a separate document by the Tel-Tek team. Here, a concise overview on fouling/clogging in microchannels and some anti-fouling strategies are presented. This issue could be significant especially in PI plants. 9.7.1 “Ice pigging” for fouling removal Professor Joe Quarini of Bristol University invented a method for cleaning out solid deposits (fouling) in pipelines and heat exchanger tubes using a non-polluting medium: ice. This “ice pig” replaces conventional pigs that are pushed through pipes to clean the interiors, but do not disintegrate in a benign manner, which means that they must be removed at some point along the pipe. The ice pig consists of crushed ice in water with a freezing point depressant. 86PDF Image | Solids handling for intensified process technology

PDF Search Title:

Solids handling for intensified process technologyOriginal File Name Searched:

solids-handling-sdr.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |