PDF Publication Title:

Text from PDF Page: 101

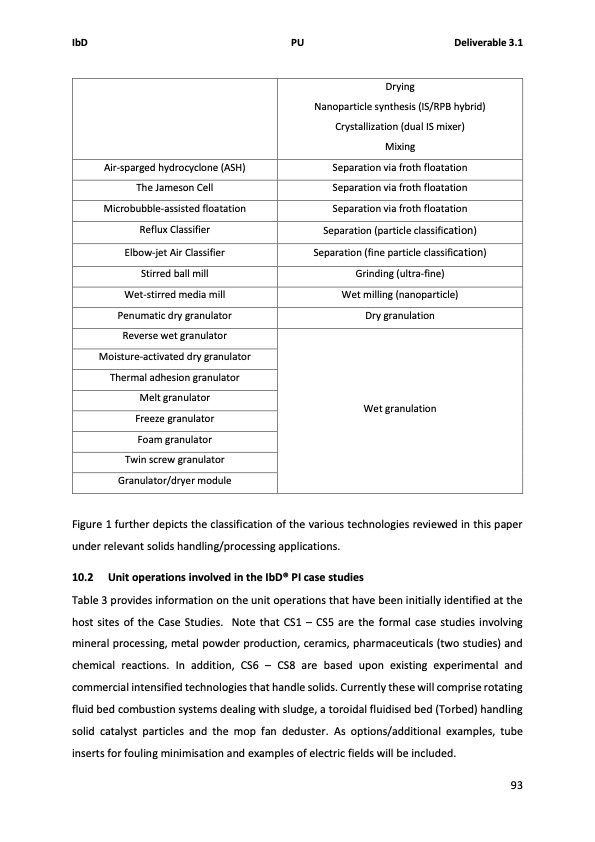

IbD PU Deliverable 3.1 Drying Nanoparticle synthesis (IS/RPB hybrid) Crystallization (dual IS mixer) Mixing Air-sparged hydrocyclone (ASH) The Jameson Cell Microbubble-assisted floatation Reflux Classifier Elbow-jet Air Classifier Stirred ball mill Wet-stirred media mill Penumatic dry granulator Reverse wet granulator Moisture-activated dry granulator Thermal adhesion granulator Melt granulator Freeze granulator Foam granulator Twin screw granulator Granulator/dryer module Separation via froth floatation Separation via froth floatation Separation via froth floatation Separation (particle classification) Separation (fine particle classification) Grinding (ultra-fine) Wet milling (nanoparticle) Dry granulation Wet granulation Figure 1 further depicts the classification of the various technologies reviewed in this paper under relevant solids handling/processing applications. 10.2 Unit operations involved in the IbD® PI case studies Table 3 provides information on the unit operations that have been initially identified at the host sites of the Case Studies. Note that CS1 – CS5 are the formal case studies involving mineral processing, metal powder production, ceramics, pharmaceuticals (two studies) and chemical reactions. In addition, CS6 – CS8 are based upon existing experimental and commercial intensified technologies that handle solids. Currently these will comprise rotating fluid bed combustion systems dealing with sludge, a toroidal fluidised bed (Torbed) handling solid catalyst particles and the mop fan deduster. As options/additional examples, tube inserts for fouling minimisation and examples of electric fields will be included. 93PDF Image | Solids handling for intensified process technology

PDF Search Title:

Solids handling for intensified process technologyOriginal File Name Searched:

solids-handling-sdr.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |