PDF Publication Title:

Text from PDF Page: 011

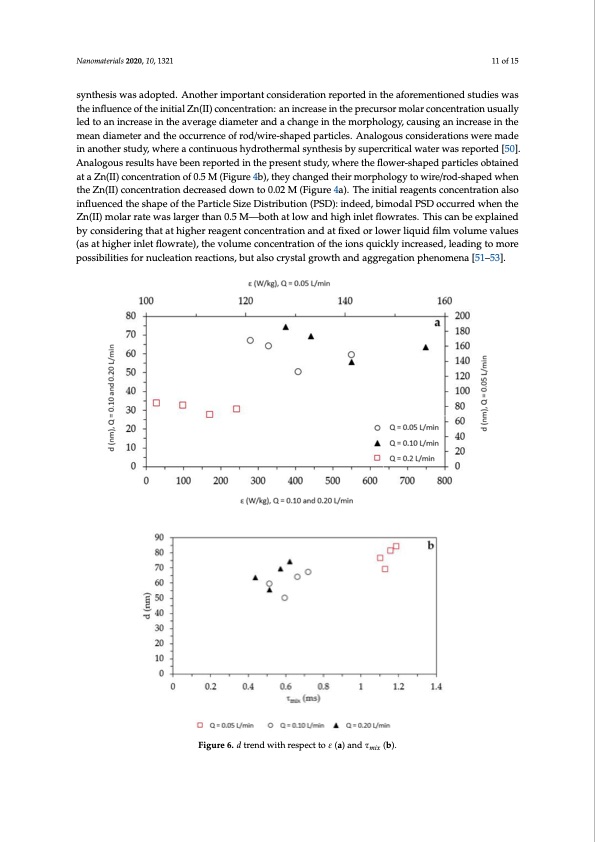

Nanomaterials 2020, 10, 1321 11 of 15 synthesis was adopted. Another important consideration reported in the aforementioned studies was the influence of the initial Zn(II) concentration: an increase in the precursor molar concentration usually led to an increase in the average diameter and a change in the morphology, causing an increase in the mean diameter and the occurrence of rod/wire-shaped particles. Analogous considerations were made in another study, where a continuous hydrothermal synthesis by supercritical water was reported [50]. Analogous results have been reported in the present study, where the flower-shaped particles obtained at a Zn(II) concentration of 0.5 M (Figure 4b), they changed their morphology to wire/rod-shaped when the Zn(II) concentration decreased down to 0.02 M (Figure 4a). The initial reagents concentration also influenced the shape of the Particle Size Distribution (PSD): indeed, bimodal PSD occurred when the Zn(II) molar rate was larger than 0.5 M—both at low and high inlet flowrates. This can be explained by considering that at higher reagent concentration and at fixed or lower liquid film volume values (as at higher inlet flowrate), the volume concentration of the ions quickly increased, leading to more Nanomaterials 2020, 10, x FOR PEER REVIEW 11 of 15 possibilities for nucleation reactions, but also crystal growth and aggregation phenomena [51–53]. Figure 6. d trend with respect to ε (a) and τ (b). Figure 6. d trend with respect to ε (a) and τmixm(bix). The mean particle’s diameter trend with respect to ε and τmix was, of course, analogous, as the latter parameter depends on the former, and showed that the same minimum occurred for ri = 2.5 cm, at all Q values. The order of magnitude of ε and τmix were in line with those obtained in a previous study, working at similar operative conditions (Q = 0.1–0.2 L/min) [34]. It has already been demonstrated that when the mixing time of the SDR is in the order of 0.1–1 ms, the obtained particles can reach dimensions lower than 100 nm, as obtained in the present study [35]. The subsequent runs were performed by fixing the Q to 0.1 L/min and the ri to 2.5 cm, accordingPDF Image | Spinning Disk Reactor Nano Production Intensification

PDF Search Title:

Spinning Disk Reactor Nano Production IntensificationOriginal File Name Searched:

nanomaterials-10-01321.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |