PDF Publication Title:

Text from PDF Page: 002

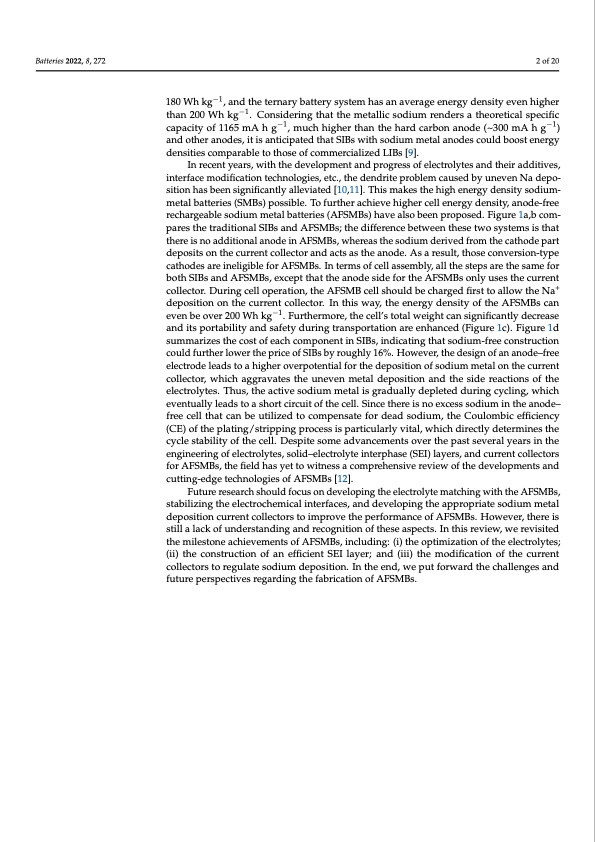

Batteries 2022, 8, 272 2 of 20 180 Wh kg−1, and the ternary battery system has an average energy density even higher than 200 Wh kg−1. Considering that the metallic sodium renders a theoretical specific capacity of 1165 mA h g−1, much higher than the hard carbon anode (~300 mA h g−1) and other anodes, it is anticipated that SIBs with sodium metal anodes could boost energy densities comparable to those of commercialized LIBs [9]. In recent years, with the development and progress of electrolytes and their additives, interface modification technologies, etc., the dendrite problem caused by uneven Na depo- sition has been significantly alleviated [10,11]. This makes the high energy density sodium- metal batteries (SMBs) possible. To further achieve higher cell energy density, anode-free rechargeable sodium metal batteries (AFSMBs) have also been proposed. Figure 1a,b com- pares the traditional SIBs and AFSMBs; the difference between these two systems is that there is no additional anode in AFSMBs, whereas the sodium derived from the cathode part deposits on the current collector and acts as the anode. As a result, those conversion-type cathodes are ineligible for AFSMBs. In terms of cell assembly, all the steps are the same for both SIBs and AFSMBs, except that the anode side for the AFSMBs only uses the current collector. During cell operation, the AFSMB cell should be charged first to allow the Na+ deposition on the current collector. In this way, the energy density of the AFSMBs can even be over 200 Wh kg−1. Furthermore, the cell’s total weight can significantly decrease and its portability and safety during transportation are enhanced (Figure 1c). Figure 1d summarizes the cost of each component in SIBs, indicating that sodium-free construction could further lower the price of SIBs by roughly 16%. However, the design of an anode–free electrode leads to a higher overpotential for the deposition of sodium metal on the current collector, which aggravates the uneven metal deposition and the side reactions of the electrolytes. Thus, the active sodium metal is gradually depleted during cycling, which eventually leads to a short circuit of the cell. Since there is no excess sodium in the anode– free cell that can be utilized to compensate for dead sodium, the Coulombic efficiency (CE) of the plating/stripping process is particularly vital, which directly determines the cycle stability of the cell. Despite some advancements over the past several years in the engineering of electrolytes, solid–electrolyte interphase (SEI) layers, and current collectors for AFSMBs, the field has yet to witness a comprehensive review of the developments and cutting-edge technologies of AFSMBs [12]. Future research should focus on developing the electrolyte matching with the AFSMBs, stabilizing the electrochemical interfaces, and developing the appropriate sodium metal deposition current collectors to improve the performance of AFSMBs. However, there is still a lack of understanding and recognition of these aspects. In this review, we revisited the milestone achievements of AFSMBs, including: (i) the optimization of the electrolytes; (ii) the construction of an efficient SEI layer; and (iii) the modification of the current collectors to regulate sodium deposition. In the end, we put forward the challenges and future perspectives regarding the fabrication of AFSMBs.PDF Image | Anode-Free Rechargeable Sodium-Metal Batteries

PDF Search Title:

Anode-Free Rechargeable Sodium-Metal BatteriesOriginal File Name Searched:

batteries-08-00272.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |