PDF Publication Title:

Text from PDF Page: 008

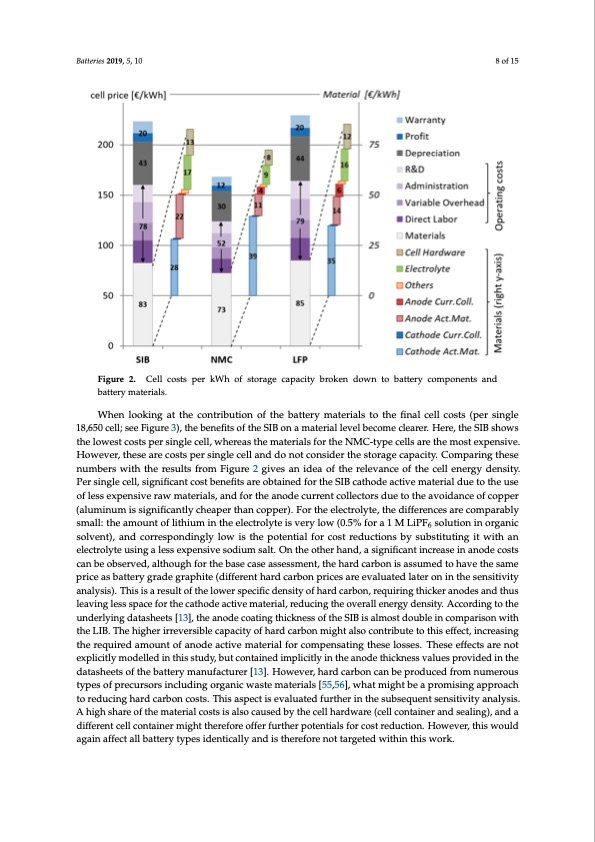

Batteries 2019, 5, 10 8 of 15 Batteries 2019, 5, x FOR PEER REVIEW 8 of 15 Figure 2. Cell costs per kWh of storage capacity broken down to battery components and Figure 2. Cell costs per kWh of storage capacity broken down to battery components and battery materials. When looking at the contribution of the battery materials to the final cell costs (per single 18,650 cell; see Figure 3), the benefits of the SIB on a material level become clearer. Here, the SIB shows the lowest costs per single cell, whereas the materials for the NMC-type cells are the most expensive. However, these are costs per single cell and do not consider the storage capacity. Comparing these numbers with the results from Figure 2 gives an idea of the relevance of the cell energy density. Per single cell, significant cost benefits are obtained for the SIB cathode active material due to the use of less expensive raw materials, and for the anode current collectors due to the avoidance of copper (aluminum is significantly cheaper than copper). For the electrolyte, the differences are comparably small: the amount of lithium in the electrolyte is very low (0.5% for a 1 M LiPF6 solution in organic solvent), and correspondingly low is the potential for cost reductions by substituting it with an electrolyte using a less expensive sodium salt. On the other hand, a significant increase in anode costs can be observed, although for the base case assessment, the hard carbon is assumed to have the same price as battery grade graphite (different hard carbon prices are evaluated later on in the sensitivity analysis). This is a result of the lower specific density of hard carbon, requiring thicker anodes and thus leaving less space for the cathode active material, reducing the overall energy density. According to the underlying datasheets [13], the anode coating thickness of the SIB is almost double in comparison with the LIB. The higher irreversible capacity of hard carbon might also contribute to this effect, increasing the required amount of anode active material for compensating these losses. These effects are not explicitly modelled in this study, but contained implicitly in the anode thickness values provided in the battery materials. datasheets of the battery manufacturer [13]. However, hard carbon can be produced from numerous Figure 3. Contribution of battery components to total material costs per single 18650 round cell types of precursors including organic waste materials [55,56], what might be a promising approach (€/cell; disregarding different energy densities/storage capacities of the individual cells). to reducing hard carbon costs. This aspect is evaluated further in the subsequent sensitivity analysis. A high share of the material costs is also caused by the cell hardware (cell container and sealing), and a When looking at the contribution of the battery materials to the final cell costs (per single different cell container might therefore offer further potentials for cost reduction. However, this would 18,650 cell; see Figure 3), the benefits of the SIB on a material level become clearer. Here, the SIB again affect all battery types identically and is therefore not targeted within this work. shows the lowest costs per single cell, whereas the materials for the NMC-type cells are the most expensive. However, these are costs per single cell and do not consider the storage capacity.PDF Image | Exploring the Economic Potential of Sodium-Ion Batteries

PDF Search Title:

Exploring the Economic Potential of Sodium-Ion BatteriesOriginal File Name Searched:

Exploring_the_Economic_Potential_of_Sodium-Ion_Bat.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |