PDF Publication Title:

Text from PDF Page: 009

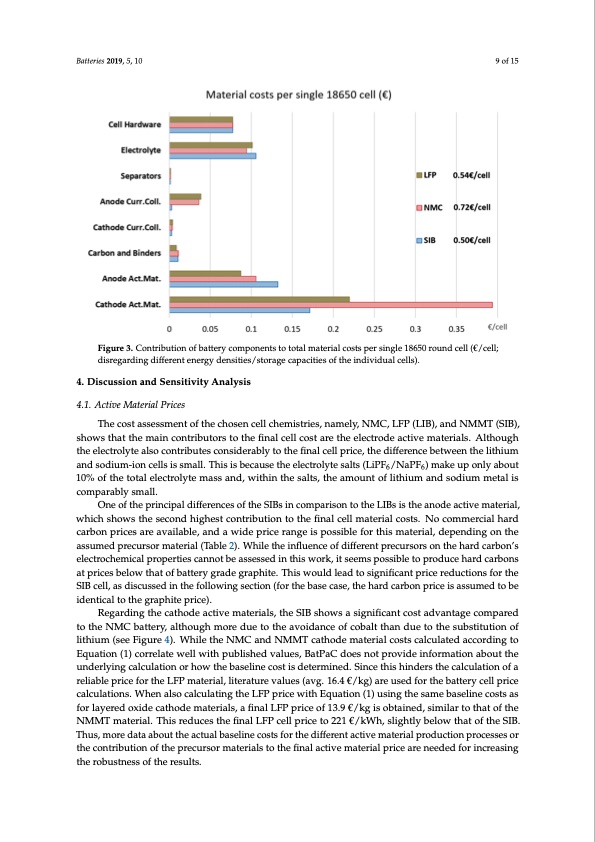

Figure 2. Cell costs per kWh of storage capacity broken down to battery components and battery Batteries 2019, 5, 10 9 of 15 materials. Figure 3. Contribution of battery components to total material costs per single 18650 round cell (€/cell; Figure 3. Contribution of battery components to total material costs per single 18650 round cell disregarding different energy densities/storage capacities of the individual cells). (€/cell; disregarding different energy densities/storage capacities of the individual cells). 4. Discussion and Sensitivity Analysis When looking at the contribution of the battery materials to the final cell costs (per single 4.18.,6A5c0tivcelMl;aseteriFailgPurrieces3),thebenefitsoftheSIBonamateriallevelbecomeclearer.Here,theSIB shows the lowest costs per single cell, whereas the materials for the NMC-type cells are the most The cost assessment of the chosen cell chemistries, namely, NMC, LFP (LIB), and NMMT (SIB), expensive. However, these are costs per single cell and do not consider the storage capacity. shows that the main contributors to the final cell cost are the electrode active materials. Although the electrolyte also contributes considerably to the final cell price, the difference between the lithium and sodium-ion cells is small. This is because the electrolyte salts (LiPF6/NaPF6) make up only about 10% of the total electrolyte mass and, within the salts, the amount of lithium and sodium metal is comparably small. One of the principal differences of the SIBs in comparison to the LIBs is the anode active material, which shows the second highest contribution to the final cell material costs. No commercial hard carbon prices are available, and a wide price range is possible for this material, depending on the assumed precursor material (Table 2). While the influence of different precursors on the hard carbon’s electrochemical properties cannot be assessed in this work, it seems possible to produce hard carbons at prices below that of battery grade graphite. This would lead to significant price reductions for the SIB cell, as discussed in the following section (for the base case, the hard carbon price is assumed to be identical to the graphite price). Regarding the cathode active materials, the SIB shows a significant cost advantage compared to the NMC battery, although more due to the avoidance of cobalt than due to the substitution of lithium (see Figure 4). While the NMC and NMMT cathode material costs calculated according to Equation (1) correlate well with published values, BatPaC does not provide information about the underlying calculation or how the baseline cost is determined. Since this hinders the calculation of a reliable price for the LFP material, literature values (avg. 16.4 €/kg) are used for the battery cell price calculations. When also calculating the LFP price with Equation (1) using the same baseline costs as for layered oxide cathode materials, a final LFP price of 13.9 €/kg is obtained, similar to that of the NMMT material. This reduces the final LFP cell price to 221 €/kWh, slightly below that of the SIB. Thus, more data about the actual baseline costs for the different active material production processes or the contribution of the precursor materials to the final active material price are needed for increasing the robustness of the results.PDF Image | Exploring the Economic Potential of Sodium-Ion Batteries

PDF Search Title:

Exploring the Economic Potential of Sodium-Ion BatteriesOriginal File Name Searched:

Exploring_the_Economic_Potential_of_Sodium-Ion_Bat.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |