PDF Publication Title:

Text from PDF Page: 005

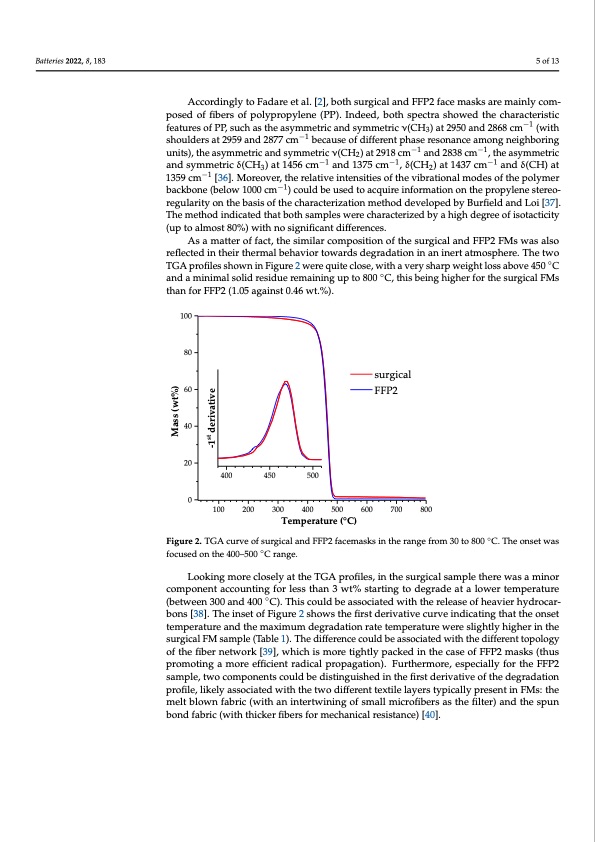

Batteries 2022, 8, 183 5 of 13 Accordingly to Fadare et al. [2], both surgical and FFP2 face masks are mainly com- posed of fibers of polypropylene (PP). Indeed, both spectra showed the characteristic features of PP, such as the asymmetric and symmetric ν(CH3) at 2950 and 2868 cm−1 (with shoulders at 2959 and 2877 cm−1 because of different phase resonance among neighboring units), the asymmetric and symmetric ν(CH2) at 2918 cm−1 and 2838 cm−1, the asymmetric and symmetric δ(CH3) at 1456 cm−1 and 1375 cm−1, δ(CH2) at 1437 cm−1 and δ(CH) at 1359 cm−1 [36]. Moreover, the relative intensities of the vibrational modes of the polymer backbone (below 1000 cm−1) could be used to acquire information on the propylene stereo- regularity on the basis of the characterization method developed by Burfield and Loi [37]. The method indicated that both samples were characterized by a high degree of isotacticity (up to almost 80%) with no significant differences. As a matter of fact, the similar composition of the surgical and FFP2 FMs was also reflected in their thermal behavior towards degradation in an inert atmosphere. The two TGA profiles shown in Figure 2 were quite close, with a very sharp weight loss above 450 ◦C Batteries 2022, 8, x FOR PEER REVIEW ◦ 6 of 15 and a minimal solid residue remaining up to 800 C, this being higher for the surgical FMs than for FFP2 (1.05 against 0.46 wt.%). 100 80 60 40 20 0 400 100 450 500 200 300 400 500 surgical FFP2 600 700 800 Temperature (°C) Figure 2. TGA curve of surgical and FFP2 facemasks in the range from 30 to 800 ◦°C. The onset was Figure 2. TGA curve of surgical and FFP2 facemasks in the range from 30 to 800 C. The onset was focused on the 400–500 ◦°C range. focused on the 400–500 C range. Looking more closely at the TGA profiles, in the surgical sample there was a minor Looking more closely at the TGA profiles, in the surgical sample there was a minor component accounting for less than 3 wt% starting to degrade at a lower temperature ◦ bhoyndsro[c3a8r]b. oTnhse[i3n8s]e.tTohfeFignuserteo2fsFhiogwurseth2eshfiorswtsdtehreivfaitrisvtedceurirvaetivnediccuartvineginthdaictatthinegonthseat tehmepoenrsaetturtemanpdertahteurmeaaxnimduthmedmegarxaimdautmiondreagteratdeamtipoenrartautreetwemerpeesrlaigtuhrtelywhiegrheesrlignhtthlye shuigrghiecralinFMthseasmuprgleic(aTlabFlMe1s)a.mThpeledi(fTfearbelnec1e)c.oTuhleddbieffaesrseoncciaetecdouwldithbethaesdsoifcfeiarteendttwopitohlotghye odfiftfhereefinbtetorpnoeltowgoyrokf[t3h9e],fwibhericnheitswmorokre[3t9ig],hwtlyhipchaciksemdoinrethtieghcatlsyepoafcFkFePd2inmtahseksca(stehuosf pFFroPm2omtinagskasm(tohruesefpfircoiemnottrinadgicalmprorpeageaffticoine)n.tFruardthicearlmporoep, aegspaeticoinal)l.yFfuortthheermFFoPre2, seasmpepcliea,lltywofocromthpeoFnFePn2ts scaomulpdleb,etdwisotincogmuipshoendenintsthceoufilrdstbderdivisatiinvgeuoifshtheeddiengrtahdeatfiorsnt pdreorfiivlaet,ilvikeeolyf tahsesodceigartaedawtioitnhpthroeftiwleo, lidkieffleyraesnstotceixatieledlwayitehrsthtyeptwicaolldyifpferreesnentteixntiFlMe lsa:ytehres (between33000anadnd400400C)°.CT)h.isTchoiusldcobueldassboeciatsesdocwiaitehdthweirtehleathseorfehleasveierofhyhderaovciaer- melt blown fabric (with an intertwining of small microfibers as the filter) and the spun typically present in FMs: the melt blown fabric (with an intertwining of small microfibers bond fabric (with thicker fibers for mechanical resistance) [40]. as the filter) and the spun bond fabric (with thicker fibers for mechanical resistance) [40]. Table 1. Main features calculated from TGA curves of surgical and FFP2 FMs. Feedstock Surgical mask FFP2 mask Tonset (°C) 430 Tmax (°C) 469 468 Residue (wt.%) a 1.05 0.46 426 a Calculated as residual wt% at 800 °C. The pyrolytic conversion of PP-based facemasks led to the production of a small amount of carbon materials and a large hydrocarbon liquid fraction together with a Mass (wt%) -1st derivativePDF Image | From Wastes to Anode Materials for Na-Ion Batteries

PDF Search Title:

From Wastes to Anode Materials for Na-Ion BatteriesOriginal File Name Searched:

batteries-08-00183.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |