PDF Publication Title:

Text from PDF Page: 003

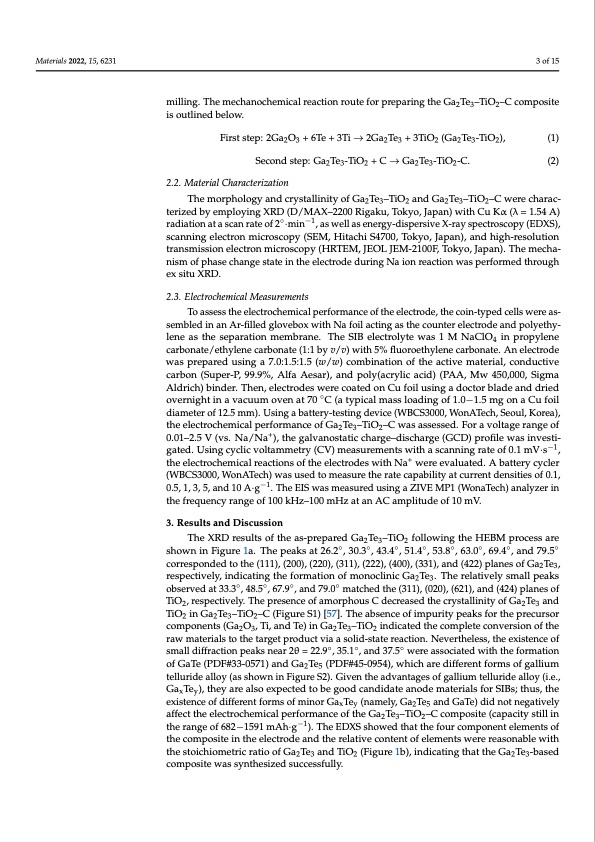

Materials 2022, 15, 6231 3 of 15 milling. The mechanochemical reaction route for preparing the Ga2Te3–TiO2–C composite is outlined below. First step: 2Ga2O3 + 6Te + 3Ti → 2Ga2Te3 + 3TiO2 (Ga2Te3-TiO2), (1) Second step: Ga2Te3-TiO2 + C → Ga2Te3-TiO2-C. (2) 2.2. Material Characterization The morphology and crystallinity of Ga2Te3–TiO2 and Ga2Te3–TiO2–C were charac- terized by employing XRD (D/MAX–2200 Rigaku, Tokyo, Japan) with Cu Kα (λ = 1.54 A) radiation at a scan rate of 2◦·min−1, as well as energy-dispersive X-ray spectroscopy (EDXS), scanning electron microscopy (SEM, Hitachi S4700, Tokyo, Japan), and high-resolution transmission electron microscopy (HRTEM, JEOL JEM-2100F, Tokyo, Japan). The mecha- nism of phase change state in the electrode during Na ion reaction was performed through ex situ XRD. 2.3. Electrochemical Measurements To assess the electrochemical performance of the electrode, the coin-typed cells were as- sembled in an Ar-filled glovebox with Na foil acting as the counter electrode and polyethy- lene as the separation membrane. The SIB electrolyte was 1 M NaClO4 in propylene carbonate/ethylene carbonate (1:1 by v/v) with 5% fluoroethylene carbonate. An electrode was prepared using a 7.0:1.5:1.5 (w/w) combination of the active material, conductive carbon (Super-P, 99.9%, Alfa Aesar), and poly(acrylic acid) (PAA, Mw 450,000, Sigma Aldrich) binder. Then, electrodes were coated on Cu foil using a doctor blade and dried overnight in a vacuum oven at 70 ◦C (a typical mass loading of 1.0−1.5 mg on a Cu foil diameter of 12.5 mm). Using a battery-testing device (WBCS3000, WonATech, Seoul, Korea), the electrochemical performance of Ga2Te3–TiO2–C was assessed. For a voltage range of 0.01–2.5 V (vs. Na/Na+), the galvanostatic charge–discharge (GCD) profile was investi- gated. Using cyclic voltammetry (CV) measurements with a scanning rate of 0.1 mV·s−1, the electrochemical reactions of the electrodes with Na+ were evaluated. A battery cycler (WBCS3000, WonATech) was used to measure the rate capability at current densities of 0.1, 0.5, 1, 3, 5, and 10 A·g−1. The EIS was measured using a ZIVE MP1 (WonaTech) analyzer in the frequency range of 100 kHz–100 mHz at an AC amplitude of 10 mV. 3. Results and Discussion The XRD results of the as-prepared Ga2Te3–TiO2 following the HEBM process are shown in Figure 1a. The peaks at 26.2◦, 30.3◦, 43.4◦, 51.4◦, 53.8◦, 63.0◦, 69.4◦, and 79.5◦ corresponded to the (111), (200), (220), (311), (222), (400), (331), and (422) planes of Ga2Te3, respectively, indicating the formation of monoclinic Ga2Te3. The relatively small peaks observed at 33.3◦, 48.5◦, 67.9◦, and 79.0◦ matched the (311), (020), (621), and (424) planes of TiO2, respectively. The presence of amorphous C decreased the crystallinity of Ga2Te3 and TiO2 in Ga2Te3–TiO2–C (Figure S1) [57]. The absence of impurity peaks for the precursor components (Ga2O3, Ti, and Te) in Ga2Te3–TiO2 indicated the complete conversion of the raw materials to the target product via a solid-state reaction. Nevertheless, the existence of small diffraction peaks near 2θ = 22.9◦, 35.1◦, and 37.5◦ were associated with the formation of GaTe (PDF#33-0571) and Ga2Te5 (PDF#45-0954), which are different forms of gallium telluride alloy (as shown in Figure S2). Given the advantages of gallium telluride alloy (i.e., GaxTey), they are also expected to be good candidate anode materials for SIBs; thus, the existence of different forms of minor GaxTey (namely, Ga2Te5 and GaTe) did not negatively affect the electrochemical performance of the Ga2Te3–TiO2–C composite (capacity still in the range of 682−1591 mAh·g−1). The EDXS showed that the four component elements of the composite in the electrode and the relative content of elements were reasonable with the stoichiometric ratio of Ga2Te3 and TiO2 (Figure 1b), indicating that the Ga2Te3-based composite was synthesized successfully.PDF Image | Ga2Te3-Based Anodes for Sodium-Ion Batteries

PDF Search Title:

Ga2Te3-Based Anodes for Sodium-Ion BatteriesOriginal File Name Searched:

materials-15-06231.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |