PDF Publication Title:

Text from PDF Page: 006

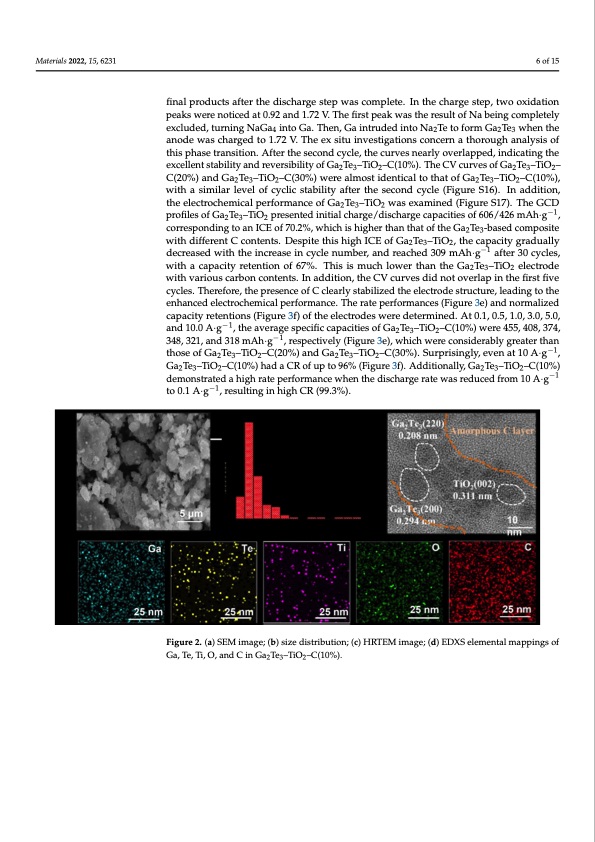

Materials 2022, 15, 6231 6 of 15 final products after the discharge step was complete. In the charge step, two oxidation peaks were noticed at 0.92 and 1.72 V. The first peak was the result of Na being completely excluded, turning NaGa4 into Ga. Then, Ga intruded into Na2Te to form Ga2Te3 when the anode was charged to 1.72 V. The ex situ investigations concern a thorough analysis of this phase transition. After the second cycle, the curves nearly overlapped, indicating the excellent stability and reversibility of Ga2Te3–TiO2–C(10%). The CV curves of Ga2Te3–TiO2– C(20%) and Ga2Te3–TiO2–C(30%) were almost identical to that of Ga2Te3–TiO2–C(10%), with a similar level of cyclic stability after the second cycle (Figure S16). In addition, the electrochemical performance of Ga2Te3–TiO2 was examined (Figure S17). The GCD profiles of Ga2Te3–TiO2 presented initial charge/discharge capacities of 606/426 mAh·g−1, corresponding to an ICE of 70.2%, which is higher than that of the Ga2Te3-based composite with different C contents. Despite this high ICE of Ga2Te3–TiO2, the capacity gradually decreased with the increase in cycle number, and reached 309 mAh·g−1 after 30 cycles, with a capacity retention of 67%. This is much lower than the Ga2Te3–TiO2 electrode with various carbon contents. In addition, the CV curves did not overlap in the first five cycles. Therefore, the presence of C clearly stabilized the electrode structure, leading to the enhanced electrochemical performance. The rate performances (Figure 3e) and normalized capacity retentions (Figure 3f) of the electrodes were determined. At 0.1, 0.5, 1.0, 3.0, 5.0, and 10.0 A·g−1, the average specific capacities of Ga2Te3–TiO2–C(10%) were 455, 408, 374, 348, 321, and 318 mAh·g−1, respectively (Figure 3e), which were considerably greater than Ga2Te3–TiO2–C(10%) had a CR of up to 96% (Figure 3f). Additionally, Ga2Te3–TiO2–C(10%) demonstrated a high rate performance when the discharge rate was reduced from 10 A·g−1 to 0.1 A·g−1, resulting in high CR (99.3%). those of Ga2Te3–TiO2–C(20%) and Ga2Te3–TiO2–C(30%). Surprisingly, even at 10 A·g−1, Materials 2022, 15, x FOR PEER REVIEW 5 of 1 Figure 2. (a) SEM image; (b) size distribution; (c) HRTEM image; (d) EDXS elemental mappings o Figure 2. (a) SEM image; (b) size distribution; (c) HRTEM image; (d) EDXS elemental mappings of Ga, Te, Ti, O, and C in Ga2Te3–TiO2–C(10%). Ga, Te, Ti, O, and C in Ga2Te3–TiO2–C(10%). The Na ion storage characteristics of the Ga2Te3–TiO2–C electrode were studied usin a half-cell form with Na metal as the counter electrode (Figure 3). The GCD voltage pro files of Ga2Te3–TiO2–C(10%), Ga2Te3–TiO2–C(20%), and Ga2Te3–TiO2–C(30%) for SIBs ar shown in Figures 3a and S7. The first discharge/charge capacities of Ga2Te3–TiO2–C(10%) Ga2Te3–TiO2–C(20%), and Ga2Te3–TiO2–C(30%) were 599/414, 550/357, and 462/27 mAh·g−1, respectively, which corresponded to initial coulombic efficiencies (ICEs) o 69.1%, 64.9%, and 60.4%, respectively. The poor reversibility between the first and secon cycles was because of the SEI layer formation in the first cycle. This poor reversion wa well documented in previous studies [58–60]. The large capacity difference between th first and second cycle indicated the large irreversible capacity contribution from the SE layer. However, the reversibility of the electrode (Ga2Te3–TiO2–C (10%) was rapidly en hanced after the second cycle, which could be confirmed by the change in coulombic effi f g - e 9 f d s e I - - ciency (Table S6). According to the EDXS results (Figure S5) and computed theoretical 5PDF Image | Ga2Te3-Based Anodes for Sodium-Ion Batteries

PDF Search Title:

Ga2Te3-Based Anodes for Sodium-Ion BatteriesOriginal File Name Searched:

materials-15-06231.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |