PDF Publication Title:

Text from PDF Page: 017

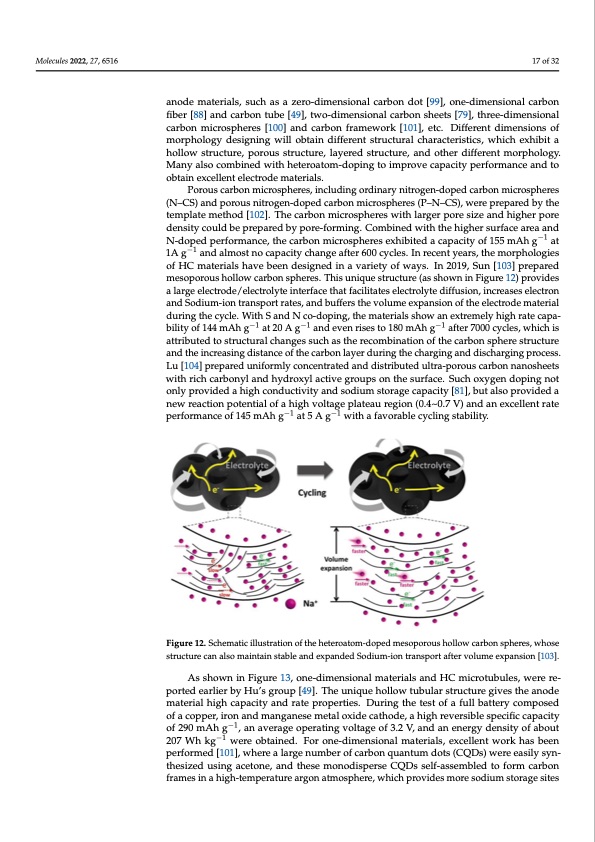

Molecules 2022, 27, 6516 17 of 32 anode materials, such as a zero-dimensional carbon dot [99], one-dimensional carbon fiber [88] and carbon tube [49], two-dimensional carbon sheets [79], three-dimensional carbon microspheres [100] and carbon framework [101], etc. Different dimensions of morphology designing will obtain different structural characteristics, which exhibit a hollow structure, porous structure, layered structure, and other different morphology. Many also combined with heteroatom-doping to improve capacity performance and to obtain excellent electrode materials. Porous carbon microspheres, including ordinary nitrogen-doped carbon microspheres (N–CS) and porous nitrogen-doped carbon microspheres (P–N–CS), were prepared by the template method [102]. The carbon microspheres with larger pore size and higher pore density could be prepared by pore-forming. Combined with the higher surface area and N-doped performance, the carbon microspheres exhibited a capacity of 155 mAh g−1 at 1A g−1 and almost no capacity change after 600 cycles. In recent years, the morphologies of HC materials have been designed in a variety of ways. In 2019, Sun [103] prepared mesoporous hollow carbon spheres. This unique structure (as shown in Figure 12) provides a large electrode/electrolyte interface that facilitates electrolyte diffusion, increases electron and Sodium-ion transport rates, and buffers the volume expansion of the electrode material during the cycle. With S and N co-doping, the materials show an extremely high rate capa- bility of 144 mAh g−1 at 20 A g−1 and even rises to 180 mAh g−1 after 7000 cycles, which is attributed to structural changes such as the recombination of the carbon sphere structure and the increasing distance of the carbon layer during the charging and discharging process. Lu [104] prepared uniformly concentrated and distributed ultra-porous carbon nanosheets with rich carbonyl and hydroxyl active groups on the surface. Such oxygen doping not only provided a high conductivity and sodium storage capacity [81], but also provided a Molecules 2022, 27, x FOR PEER REVIEW 19 of 34 new reaction potential of a high voltage plateau region (0.4~0.7 V) and an excellent rate performance of 145 mAh g−1 at 5 A g−1 with a favorable cycling stability. FFiigurre1122..SScchheemaatticicilillulustsrtaratitoionnooffthtehehehtetreoraotaotmom-d-odpopededmmeseospooprooruousshohlolollwowcacrabrobnonspshpehrerse,sw,hose whose structure can also maintain stable and expanded Sodium-ion transport after volume expan- structure can also maintain stable and expanded Sodium-ion transport after volume expansion [103]. sion [103]. As shown in Figure 13, one-dimensional materials and HC microtubules, were re- As shown in Figure 13, one-dimensional materials and HC microtubules, were re- ported earlier by Hu’s group [49]. The unique hollow tubular structure gives the anode ported earlier by Hu’s group [49]. The unique hollow tubular structure gives the anode material high capacity and rate properties. During the test of a full battery composed material high capacity and rate properties. During the test of a full battery composed of a of a copper, iron and manganese metal oxide cathode, a high reversible specific capacity copper, iron and manganese metal oxide cathode, a high reversible specific capacity of of 290 mAh g−1, an average operating voltage of 3.2 V, and an energy density of about 290 mAh g−1, an average operating voltage of 3.2 V, and an energy density of about 207 207 Wh kg−1 were obtained. For one-dimensional materials, excellent work has been Wh kg−1 were obtained. For one-dimensional materials, excellent work has been per- performed [101], where a large number of carbon quantum dots (CQDs) were easily syn- formed [101], where a large number of carbon quantum dots (CQDs) were easily syn- thesized using acetone, and these monodisperse CQDs self-assembled to form carbon thesized using acetone, and these monodisperse CQDs self-assembled to form carbon frames in a high-temperature argon atmosphere, which provides more sodium storage sites frames in a high-temperature argon atmosphere, which provides more sodium storage sites and improves the infiltration area of electrolyte, and reduces the diffusion length of the Sodium-ions. This anode material can reach a capacity of 90 mAh g−1 at 20 A g−1, and the capacity increases from 130 mAh g−1 to 137 mAh g−1 after 5000 cycles at 5 A g−1.PDF Image | Hard Carbons as Anodes in Sodium-Ion Batteries

PDF Search Title:

Hard Carbons as Anodes in Sodium-Ion BatteriesOriginal File Name Searched:

molecules-27-06516-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |