PDF Publication Title:

Text from PDF Page: 019

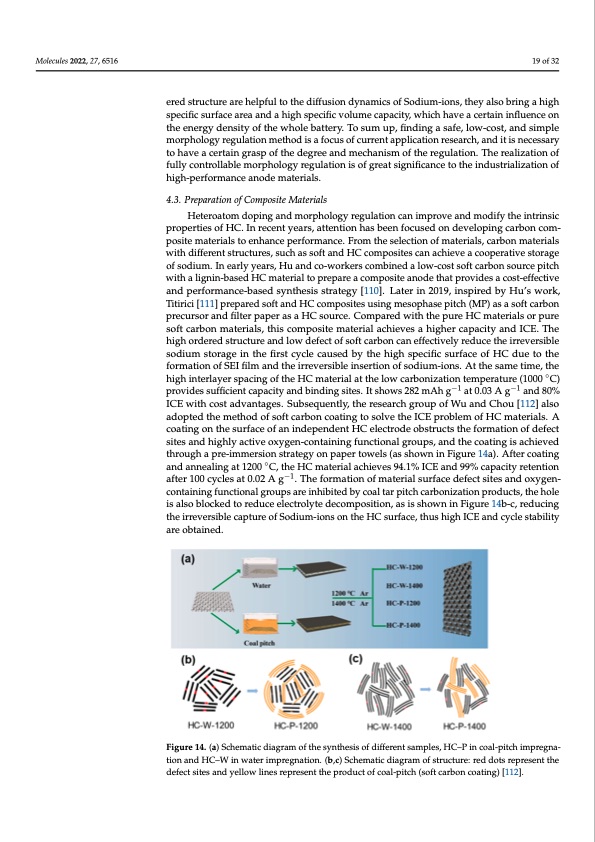

Molecules 2022, 27, 6516 19 of 32 ered structure are helpful to the diffusion dynamics of Sodium-ions, they also bring a high specific surface area and a high specific volume capacity, which have a certain influence on the energy density of the whole battery. To sum up, finding a safe, low-cost, and simple morphology regulation method is a focus of current application research, and it is necessary to have a certain grasp of the degree and mechanism of the regulation. The realization of fully controllable morphology regulation is of great significance to the industrialization of high-performance anode materials. 4.3. Preparation of Composite Materials Heteroatom doping and morphology regulation can improve and modify the intrinsic properties of HC. In recent years, attention has been focused on developing carbon com- posite materials to enhance performance. From the selection of materials, carbon materials with different structures, such as soft and HC composites can achieve a cooperative storage of sodium. In early years, Hu and co-workers combined a low-cost soft carbon source pitch with a lignin-based HC material to prepare a composite anode that provides a cost-effective and performance-based synthesis strategy [110]. Later in 2019, inspired by Hu’s work, Titirici [111] prepared soft and HC composites using mesophase pitch (MP) as a soft carbon precursor and filter paper as a HC source. Compared with the pure HC materials or pure soft carbon materials, this composite material achieves a higher capacity and ICE. The sodium storage in the first cycle caused by the high specific surface of HC due to the Molecules 2022, 27, x FOR PEER REVIEW 21 of 34 high ordered structure and low defect of soft carbon can effectively reduce the irreversible formation of SEI film and the irreversible insertion of sodium-ions. At the same time, the specific surface of HC due to the formation of SEI film and the irreversible insertion of ◦ high interlayer spacing of the HC material at the low carbonization temperature (1000 sodium-ions. At the same time, the high interlayer spacing of the HC material at the low provides sufficient capacity and binding sites. It shows 282 mAh g−1 at 0.03 A g−1 and 80% carbonization temperature (1000 °C) provides sufficient capacity and binding sites. It C) ICE with cost advantages. Subsequently, the research group of Wu and Chou [112] also shows 282 mAh g−1 at 0.03 A g−1 and 80% ICE with cost advantages. Subsequently, the adopted the method of soft carbon coating to solve the ICE problem of HC materials. A research group of Wu and Chou [112] also adopted the method of soft carbon coating to coating on the surface of an independent HC electrode obstructs the formation of defect solve the ICE problem of HC materials. A coating on the surface of an independent HC sites and highly active oxygen-containing functional groups, and the coating is achieved electrode obstructs the formation of defect sites and highly active oxygen-containing through a pre-immersion strategy on paper towels (as shown in Figure 14a). After coating functional groups, and the coating is achieved through a pre-immersion strategy on pa- and annealing at 1200 ◦C, the HC material achieves 94.1% ICE and 99% capacity retention per towels (as shown in Figure 14a). After coating and annealing at 1200 °C, the HC ma- after100cyclesat0.02Ag−1.Theformationofmaterialsurfacedefectsitesa−n1doxygen- terial achieves 94.1% ICE and 99% capacity retention after 100 cycles at 0.02 A g . The Figure 14. (a) Schematic diagram of the synthesis of different samples, HC–P in coal-pitch im- Figure 14. (a) Schematic diagram of the synthesis of different samples, HC–P in coal-pitch impregna- pregnation and HC–W in water impregnation. (b,c) Schematic diagram of structure: red dots rep- tion and HC–W in water impregnation. (b,c) Schematic diagram of structure: red dots represent the containing functional groups are inhibited by coal tar pitch carbonization products, the hole formation of material surface defect sites and oxygen-containing functional groups are inshailbsiotebdlobcykecdoatol traerdpuictechelceacrtbrolnyitzeatdioencopmropdousicttiso,nt,haeshisolsehioswanlsionbFliogcukreed1t4ob-rce,druecdeucing ethlecitrroelyvteersdibecleomcapotsuirtieoonf, aSsodisiushmo-wionsinoFnigthuereH1C4bs-uc,rfraecdeu,ctihnugsthiegihrrIeCvEerasinbdleccyacpletusrteability oarfeSodbituamin-eidon. s on the HC surface, thus high ICE and cycle stability are obtained. resent the defect sites and yellow lines represent the product of coal-pitch (soft carbon coating) defect sites and yellow lines represent the product of coal-pitch (soft carbon coating) [112]. [112]. As for other carbon materials, Lai’s group [113] directed carbon nanofibers to verti- cally penetrate through graphene sheets, constructing a robust carbon nanofiber inter- penetrated graphene architecture. The carbon fiber inhibits the stacking of the graphene layers, and the three-dimensional structure provides fast sodium transport paths,PDF Image | Hard Carbons as Anodes in Sodium-Ion Batteries

PDF Search Title:

Hard Carbons as Anodes in Sodium-Ion BatteriesOriginal File Name Searched:

molecules-27-06516-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |